Underground transformer substations

In densely populated areas of modern cities, it is difficult to find space for new substations. Energy consumption is increasing year by year, the amount of power required is increasing, and space is needed to install standard PTS. But the construction space is so limited that they can only be installed next to residential buildings or underground.

Underground transformer substations solve this problem. It is no coincidence that the interest in modular complete transformer substations in concrete buildings is increasing every year. This interest also arises because accidents sometimes occur due to the deterioration of transformer substations by 40-50% and there is only one way out: to reconstruct and replace substations, to install high-quality equipment.

An underground substation can be installed in any suitable place: in a park, under a playground, in a basement, etc. And most importantly, it will be safe for both people and the environment.Such substations, underground and buried, are produced in the form of ready-made concrete modules with already installed equipment, that is, they are completely ready-made network structures.

They are specially designed for installation in dense buildings or strict architectural requirements and limiting the height of electrical networks. Combined solutions with buried, underground and above-ground blocks can also be used.

For underground substations, the project documentation is distinguished by the need to develop additional solutions for installation, docking, waterproofing of blocks, solutions for protecting reinforced concrete from aggressive soils, for sealing cable seals, solutions for inter-block and block sealing, for emergency pumping of water, ventilation solutions, etc. The arrangement of an underground substation is a solution to the issue of energy supply without changing the appearance of the city.

One of the most popular suppliers of underground substations is the Polish company ZPUE. In Russia, underground substations of this plant have already been installed in many cities. The substations of the ZPUE enterprise make it possible to reliably, efficiently and economically solve the problems of regional power supply. These substations have a number of advantages:

-

reliability and ease of use;

-

minimizing operating costs;

-

installation in one day;

-

replaceable blocks;

-

the ability to adapt to individual customer requirements;

-

wide climatic range.

ZPUE underground transformer substations are suitable for working with a cable or cable network, made in a radial or ring pattern.The substation blocks are delivered to the installation site fully assembled and for commissioning it remains only to perform the grounding, connect the cables and the power supply transformers.

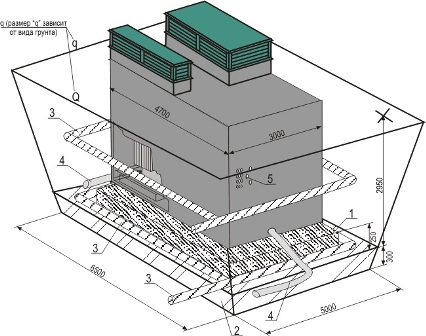

Depending on the required capacity, an underground transformer substation may consist of one or several sealed concrete containers installed underground. An entrance (with ventilation function) and a ventilation duct located above the transformers remain on the surface of the ground.

The exits of the ventilation channel and the hatch are closed with strong bars, on which you can safely walk. Special visors are provided to protect against dirt and rainwater. To go down the stairs to the substation room, it is enough to open the lock and remove the hatch cover. There are doors on the landing leading to a low and medium board. The panels are cooled by ventilation ducts.

There is also a sewage system at the substation: the floor is at a height of 0.3 m from the bottom, there are two channels, they are connected to the existing sewage system. The space between the bottom and the floor serves to collect condensate and water that enters the underground substation during rain through an open hatch.

The transformer is mounted on rails, under the rails there is a sealed pallet, the volume of which allows to hold all the transformer oil. The design of the substation allows it to accommodate two transformers with a capacity of up to 1.6 MVA. To install the transformer, simply remove the hatch grill, dismantle the walls of the transformer chamber and the steps.

Here we talked about a passing substation equipped with two dry transformers with a capacity of 1.6 MVA each, with a transformer compartment and a special subscriber section, as well as with active ventilation. On the high voltage side, TMP24 type gas-insulated switchgear is used. On the low voltage side, ZR-W cells are used, there is an ATS function.

Another example is the underground concrete complete transformer substations (BKTP) of the German company Betonbau of the UW 630-1250 kVA series. They are used as distribution and consumer substations for voltages up to 35 kV.

Inside Betonbau underground substations of the UW 630-1250 kVA series, it is possible to install high-voltage cabinets, insulated with air and SF6 gas, transformers up to 1000 kVA, low-voltage switchboards with a current load of up to 1600 A, compensated switchboards, as well as USM measuring cabinets.

Betonbau underground substations are presented in the following varieties:

-

BKTP UW 3048;

-

BKTP UW 3054;

-

BKTP UW 3060.

These substations in the installed form are completely invisible, for this reason they have found wide application where conventional substations cannot be installed for some reason. The UW substations of the upper model range are 3 meters wide. The length can be from 2.4 m to 6.6 m with a step of 0.6 m. These models can differ in the following characteristics related to the wishes of the customer:

-

water resistance;

-

oil tightness;

-

load capacity;

-

low noise level.

The structure is installed at a depth of 4 meters in the ground, and if an intermediate floor is used, then the height of the above-ground part will be 2.4 meters, and the height of the underground cable part is 0.8 meters.The system is a monolithic body made in the form of a separate casting (bell casting), which gives:

-

high mechanical strength;

-

exceptional density;

-

water resistance;

-

it also has an oil sump function in case of emergency;

-

fire resistance;

-

ease of transportation;

-

corrosion resistance.

The effective ventilation system eliminates the formation of condensation on the walls and also protects against rodents and insects. Even in the event of a short circuit, the products of combustion will not pose a danger to passers-by or service personnel. Hatches and doors of the electric trunk are not dangerous for them neither arcing nor short circuit.

Betonbau branded panels are equipped with technological openings (holes) for the introduction of cables, they are cast from aluminum alloys, it is possible to connect all standard cables widely used in electricity today. At the customer's request, penetrations of other manufacturers can also be installed. The proven technology of hermetically sealed joints allows the production of even larger volumes of underground objects.