Asynchronous motors of the AIR series - technical characteristics

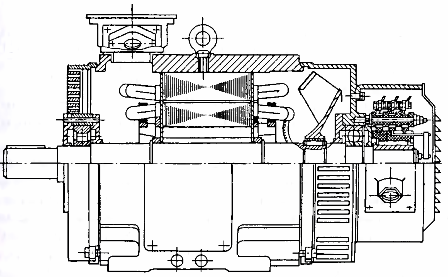

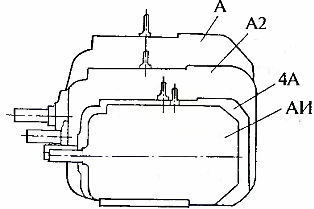

A series of asynchronous electric motors AI - asynchronous electric motors Interelectro (Fig. 1) was created by a team of specialists from the countries participating in Interelectro. In fig. 2 shows for comparison the dimensions of asynchronous electric motors of the A, A2, 4A, AI series. The AI series provides the basic version as well as mods and specialized versions. Electric motors of the AI series have a power range from 0.025 to 400 kW and a range of rotation axis heights from 45 to 355 mm.

A series of asynchronous electric motors AI - asynchronous electric motors Interelectro (Fig. 1) was created by a team of specialists from the countries participating in Interelectro. In fig. 2 shows for comparison the dimensions of asynchronous electric motors of the A, A2, 4A, AI series. The AI series provides the basic version as well as mods and specialized versions. Electric motors of the AI series have a power range from 0.025 to 400 kW and a range of rotation axis heights from 45 to 355 mm.

In the electric motors of the AI series, two possibilities for connecting the rows of powers and heights of the axis of rotation are adopted: P and C (respectively, the series of electric motors are called AIR and AIS).

The first variant corresponds to the connection previously adopted in the USSR, the second - to the SENE-LEC / CENELEK standards (document 2B / 64). The SENELEC / CENELEK standards are the European Electrotechnical Committee for Standardization standards that regulate the connection of power series and installation dimensions.

Almost all European and American companies located abroad are led by them. Therefore, for the domestic market, electric motors of the AI series have the P (AIR) version, for export - the C (AIS) version. In the P version (AIR series), the power of the electric motors at the same height of the rotation axis is usually one step higher than the power in the C version (AIS series).

Rice. 1. AI series phase rotor electric motor

Rice. 2. Comparison of sizes of A, A2, 4A and AI series (The first unified series of general-purpose induction motors A, AO was mastered in 1949. In 1961, the second unified series of electric motors A2, AO2 was mastered. Since 1975 .it has been replaced by the 4A, 4AN series).

In the AI series, three types of designations are adopted: basic, basic and full. The main designation is a combination of symbolic elements that determine the series, its power, rotation frequency (series designation, the ability to connect the power with the mounting dimensions, the height of the axis of rotation, the mounting dimensions of the length of the frame and the length of the magnetic circuit of the stator, the number of poles), for example: AIR200 Mb (series AI, connection according to version P, height of the axis of rotation 200 mm, body length according to the installation dimensions M, number of poles 6 ).

The basic designation is a combination of the basic designation of the electric motor with the designation of the type of protection and cooling, electrical and structural modifications, specialized design and performance according to environmental conditions, for example: AIRBS100M4NPT2 (AIR100M4 is the basic designation, B is a closed version with natural cooling without blowing, C is with increased sliding, H — low noise, P — with increased accuracy of installation dimensions, T — for tropical climate, 2 — placement category).

Full designation — a combination of the basic designation with additional electrical and design features, for example: AIRBS100M4NPT2 220/380 V, 60IM218I, KZ -N -3, F -100, (AIRBS100M4NPT2 — basic designation, 220/380 V — voltage, 60 — mains frequency, IM2181 — version according to the mounting method and on the end of the shaft, KZ -N -3 — version of the output device and the number of connectors, F100 — version of the flange shield).

Letters from the Russian and Latin alphabets can be used in the designation. According to the type of protection and cooling, the design has the following designations: closed with external blowing of the case with a built-in fan — not indicated, closed with natural cooling — B (V), protected — N (N), open — L (L), built-in — V (V), closed blown — P (R), with an attached fan from a separate electric motor — F (F).

The electrical modification has the following designations: with increased slip — C (C), with increased starting moment — P (R), with variable speed — X (X), with a phase rotor — K (K), single-phase with a working capacitor — E ( E), single-phase with starting and working capacitor — UE (YE), for short-term operation — KR (KR).

The height of the axis of rotation is indicated by numbers from 45 to 355 mm (45, 50, 56.63, 71, 80, 90, 100, 112, 132, 160, 180, 200, 225, 250, 280, 315, 355 mm) .

Installation dimensions along the length of the frame and the stator core are indicated by the letters of the Latin alphabet: the first length of the core — A, the second length of the core — B, the third length of the core — C, the first length of the frame — S , the second length of the frame — M, the third length of the frame — L, the first length of the bed with a core of the first length is SA, the first length of the bed with a core of the second length is SB, the third length of the bed with a core of the first length is LA, the third length of the bed with the cores of the second length is LB.

The number of poles is indicated by numbers: 2,4, 6, 8, 10, 12; two-speed electric motors — 4/2, 6/4, 8/4, 8/6; three-speed electric motors — 6/4/2, 8/6/4, 8/4/2.

Design modifications have the following designations: with temperature protection — B (V), low noise — N (N), with increased accuracy of installation dimensions — P (R), with high accuracy of installation dimensions — P2 (P2), with built-in electromagnetic brake — E (E).

The stator cores of electric motors with a height of the rotation axis of 45 — 132 mm are fixed by welding, and with the heights of the rotation axis of 160 — 355 mm — with the help of clamps. The stator core of the AI series electric motors is assembled from electrical steel 0.5 mm thickness, unalloyed, low- and medium-alloyed with electro-insulating varnish coating.

The winding of the stator of electric motors with an axis rotation height of 45 — 250 mm is loose, of round wire, fits into the semi-closed slots of the stator.For electric motors with a rotation axis height of 280 — 355 mm, the stator winding is made of rigid coils of rectangular wire, which are placed in semi-open slots of the stator.

The stator winding of electric motors with a rotation axis height of 45-132 mm is single-layer, concentric or for two-pole shaking electric motors. Electric motors with rotation axes 160-250 mm are made with a single- or double-layer winding. For electric motors with heights of the axis of rotation 45 — 63 mm, an insulation system with heat resistance class B is adopted, with heights of the axis of rotation 71 — 250 mm — classes B and F, with heights of the axis of rotation 280 — 355 mm — class F .

The short-circuited windings of the rotors of electric motors at all heights of the rotation axis are made by filling the rotor core with aluminum. At the same time, short connecting rings with ventilation blades are cast, and for some heights of the axis of rotation - with pins for attaching balance weights. To reduce magnetic noise and reduce additional moments, the rotor slots of the electric motors at a number of heights of the axis of rotation are made with a bevel of one tooth pitch.

Electric motors at all heights of the axis of rotation have rolling bearings. AIR and AIS series electric motors produce two types of bearing assembly design: the first is common, the second is with design change device and lubricant. To reduce noise and vibrations in the bearing blocks of electric motors with a rotation height of 45 — 132 mm, spring washers are used for axial compression of the bearings.

Air motors — basic technical characteristics

Electrical motor

Power

kWh

Revolutions per minute

Current at

380V, A

KPD,%

Coef.

powerful

Ip / In

Weight, kg

AIR 56 A2

0,18

3000

0,55

65

0,78

5

3,5

AIR 56 B2

0,25

3000

0,73

66

0,79

5

3,8

AIR 56 A4

0,12

1500

0,5

57

0,66

5

3,6

AIR 56 B4

0,18

1500

0,7

60

0,68

5

4,2

AIR 63 A2

0,37

3000

0,9

72

0,84

5

5,2

AIR 63 B2

0,55

3000

1,3

75

0,81

5

6,1

AIR 63 A4

0,25

1500

0,9

65

0,67

5

5,1

AIR 63 B4

0,37

1500

1,2

68

0,7

5

6

AIR 63 A6

0,18

1000

0,8

56

0,62

4

4,8

AIR 63 B6

0,25

1000

1,0

59

0,62

4

5,6

AIR 71 A2

0,75

3000

1,3

79

0,8

6

8,7

AIR 71 B2

1,1

3000

2,6

79,5

0,8

6

9,5

AIR 71 A4

0,55

1500

1,7

71

0,71

5

8,1

AIR 71 B4

0,75

1500

1,9

72

0,75

5

9,4

AIR 71 A6

0,37

1000

1,4

65

0,63

4,5

8,6

AIR 71 B6

0,55

1000

1,8

69

0,68

4,5

9,9

AIR 80 A2

1,5

3000

3,6

82

0,85

6,5

13,3

AIR 80 B2

2,2

3000

5,0

83

0,87

6,4

15,0

AIR 80 A4

1,1

1500

3,1

76,5

0,77

5,0

12,8

AIR 80 B4

1,5

1500

3,9

78,5

0,80

5,3

14,7

AIR 80 A6

0,75

1000

2,3

71

0,71

4,0

12,5

AIR 80 V6

1,1

1000

3,2

75

0,71

4,5

16,2

AIR 80 A8

0,27

750

1,5

58

0,59

3,5

14,7

AIR 80 V8

0,55

750

2,2

58

0,60

3,5

15,9

AIR 90 L2

3

3000

6,5

84,5

0,85

7,0

20,0

AIR 90 L6

1,5

1000

4,2

76

0,70

5,0

20,6

AIR 90 LA8

0,75

750

2,4

70

0,71

4,0

19,5

AIR 90 LB8

1,1

750

3,3

74

0,72

4,5

22,3

AIR 100 S2

4

3000

8,4

87

0,88

7,5

30,0

AIR 100 L2

5,5

3000

11,0

88

0,88

7,5

32,0

AIR 100 S4

3

1500

7,2

82

0,82

7,0

34,0

AIR 100 L4

4

1500

9,3

85

0,84

7,0

29,2

AIR 100 L6

2,2

1000

5,9

81,5

0,74

6,0

27,0

AIR 100 L8

1.5

750

4,5

76,5

0,70

3,7

26,0

AIR 112 M2

7.5 / 7.6 kW

3000

14,7

87,5

0,88

7,5

48

AIR 112 M4

5.5kw

1500

11,3

85,5

0,86

7

45

AIR 112 MA6

3 kW

1000

7,4

81

0,76

6

43

AIR 112 MV6

4 kW

1000

9,1

82

0,81

6

48

AIR 112 MA8

2.2 kW

750

6,16

76,5

0,71

6

43

AIR 112 MV8

3 kW

750

7,8

79

0,74

6

48

AIR 132 M2

11 kW

3000

21,1

88

0,9

7,5

78

AIR 132 S4

7.5 / 7.6 kW

1500

15,1

87,5

0,86

7,5

70

AIR 132 M4

11 kW

1500

22,2

88,5

0,85

7,5

84

AIR 132 S6

5.5kw

1000

12,3

85

0,8

7

69

AIR 132 M6

7.5 / 7.6 kW

1000

16,5

85,5

0,81

7

82

AIR 132 S8

4 kW

750

10,5

83

0,7

6

69

AIR 132 M8

5.5kw

750

13,6

83

0,74

6

82

AIR 160 S2

15 kW

3000

30

88

0,86

7,5

116

AIR 160 M2

18.5 kW

3000

35

90

0,88

7,5

130

AIR 160 S4

15 kW

1500

29

89

0,87

7

120

AIR 160 M4

18.5 kW

1500

35

90

0,89

7

142

AIR 160 S6

11 kW

1000

23

87

0,82

6,5

125

AIR 160 M6

15 kW

1000

31

89

0,82

7

150

AIR 160 M8

11 kW

750

26

87

0,68

6

150

AIR 180 S2

22 kW

3000

41,5

90,5

0,89

7

150

AIR 180 M2

30 kW

3000

55,4

91,5

0,9

7,5

170

AIR 180 S4

22 kW

1500

42,5

90,5

0,87

7

160

AIR 180 M4

30 kW

1500

57

92

0,87

7

190

AIR 180 M6

18 kW

1000

36,9

89,5

0,85

6,5

160

AIR 180 M8

15 kW

750

31,3

89

0,82

5,5

172

AIR 200 M2

37 kW

3000

71

91

0,87

7

230