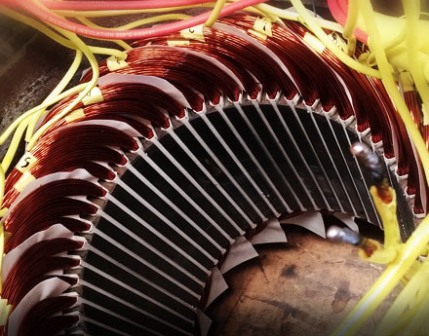

Low voltage motor fault class

Readers are offered the following list of the most common defects in electric motors:

Readers are offered the following list of the most common defects in electric motors:

-

operation of the electric motor in two phases;

-

turn-by-turn closure;

-

overload and overheating of the stator of the electric motor;

-

rotor imbalance;

-

breaking or loosening the fastening of the bars in the squirrel cage;

-

incorrect arrangement of shafts;

-

uneven air gap between the stator and the rotor;

-

damage to the stator windings or insulation;

-

loosening of the fastening of the stator winding, defects in the connectors, damage to the bearings.

In turn, the experts added their own list of problems with electric motors, including:

-

increased noise level;

-

motor shaft stop;

-

redirection of output wires,

-

closure between sheets of active steel;

-

damage to lead wires;

-

open circuit connections;

-

housing short circuit;

-

aging of the insulation;

-

mismatch of rotor and stator;

-

capacitor breakage;

-

coil assembly errors and a number of others.

The squirrel cage induction motor is still the most common power element today. According to some reports, the number of engines operating in the country's economy reaches tens of millions. However, electric motor failures cause disruptions in technological processes, which causes significant damage to the economy due to product shortages, downtime, lost profits, etc. etc.

In addition, a large amount of materials (winding, electrical steel, insulating material), electricity, working time is spent on the repair, restoration of electric motors. For the most part, electric motors are in difficult working conditions: they are improperly loaded, work for a short time, with long interruptions, the voltage is unstable, with variable asymmetry, dust, humidity, aggressive gases, significant temperature fluctuations plus low qualification of service personnel — all this negatively affects their work.

According to some reports, with an average (estimated) service life of 15 years (operating time 40 thousand hours), about 20% of electric motors fail annually. The average damage from the failure of one electric motor today exceeds the amount of 6,000 rubles. The amount of damages includes costs: direct costs related to the repair and replacement of electric motors, and technological costs related to losses from fires and downtime of technological equipment, lost profit, etc.

The most common defects in electric motors:

1. Overloading and overheating of the stator of the electric motor — 31%;

2. Turn-to-turn closing-15%;

3. Bearing damage — 12%;

4. Damage to the stator windings or insulation — 11%;

5.Uneven air gap between the stator and the rotor — 9%;

6. Operation of an electric motor on two phages — 8%;

7. Breakage or loosening of the bars in the squirrel cage — 5%;

8. Loosening of the fastening of the stator winding — 4%;

9. Rotor imbalance — 3%;

10. Shaft displacement — 2%.

The operational reliability of electric motors determines the efficiency of the use of all technical means used in production and affects the most important economic indicators of production. The practically observed insufficient reliability of electric machines leads to large additional costs for premature repairs and unplanned downtime of the equipment. Currently, one of the most important characteristics of the operation of an electric drive is its reliability, as well as a quantitative assessment of this indicator.

Asynchronous and synchronous electric drives make up at least 73% of the total number of electric drives, they consume more than half of the electricity produced in the country. According to existing forecasts, asynchronous and synchronous motors will remain the main converters of electrical energy into mechanical energy for several decades.

Such widespread use of alternating current electric machines, which are the basis of the electric drive of most industrial, technological and utility processes, shows this. that technical progress largely depends on the quality of the asynchronous and synchronous motors used and the reliability of their operation in operation.

Series E.V.