Reactive Power Compensation Controllers

Specialists in many fields have been dealing with the issue of industrial process automation for a long time. And year after year, the supporting infrastructure of many enterprises is gradually moving from manual to automatic management. Enterprise automation and electrification systems are affected and this topic is hard to overstate.

Specialists in many fields have been dealing with the issue of industrial process automation for a long time. And year after year, the supporting infrastructure of many enterprises is gradually moving from manual to automatic management. Enterprise automation and electrification systems are affected and this topic is hard to overstate.

The energy consumption of a powerful enterprise is always related to energy costs, which must be minimized as much as possible. Innovation helps solve this problem. Power systems need to be modernized and improving the quality of electricity will lead to a reduction in production costs.

Means of control and operational management of power supply systems measure the parameters of the systems, change their characteristics, optimize the operation mode of the equipment, increase its service life and minimize the percentage of accidents and rejections.This is achieved by rationalizing the distribution and consumption of energy resources in the enterprise.

Primarily for the majority of loads in factories and workshops, their inductive nature is inherent. Electric motors for metal cutting machines, fluorescent lighting systems, power supplies for various equipment. All these devices load wires and cables with a current up to 2 times stronger than the rated current, and these are heating losses that increase 4 times. In addition, the power transformers must be more powerful and this is an additional cost.

Usually, the problem is solved by connecting capacitors in parallel with inductive loads to bring the nature of the consumption closer to the active one. But it is not always profitable to equip every device with capacitors, so the battery of capacitors is connected to a power supply that powers several consumers at the same time. And users can operate independently, turning on and off at specific times, sometimes unpredictably, so the task arises of automating the connection of the exact set of capacitors needed at a given time to compensate for the current inductive load.

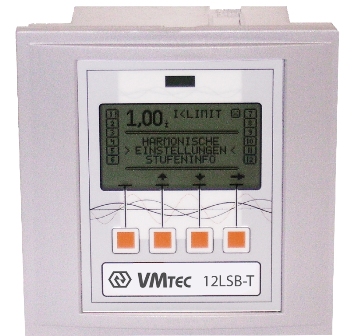

Reactive power compensation controllers successfully cope with this task. Installing reactive power compensation consisting of several capacitors, the capacities of which allow you to choose any combination, allows you to smoothly change the total connected compensation capacity at any time.The microprocessor based controller monitors the inductive component of the current in real time and at the appropriate time connects or disconnects the appropriate capacitance, the required number of capacitors.

The most modern controllers have a number of additional functions. In particular, the controller can measure the parameters of the capacitors, their temperature, whether there is an overvoltage, whether there are harmonics, and if the parameters exceed the critical values, the capacitor at risk will be shut down. Priority when connecting will have the capacitors with the largest working resource, that is, those that work less. The parameters of the condenser unit are measured and transferred for computer processing. That is, the controller can be integrated into the information network of the enterprise.

Regulators are constantly being improved, their algorithms are optimized and the efficiency of installations increases. More recently, instantaneous access controllers were popular, when according to the current value of the power factor, a capacitor bank with the necessary capacity was immediately connected to bring the power factor to unit or up to a predetermined value. This algorithm has low accuracy of keeping the mean power factor and is fraught with overcompensation.

More modern controllers track not the instantaneous value of the power factor, but its average value over a certain period of time, and the connection time of the capacitors also varies depending on the operating conditions of the equipment. As a result, the load power factor is maintained at a constant set level at all times and the meter records this.

Modern controllers have the ability to easily switch, if necessary, from the average value measurement mode to the instantaneous power factor measurement mode, that is, the user decides for himself what he wants from the reactive power compensation installation.

The capacitor steps are adjusted according to the amount of reactive power added or subtracted, you can set any value for the power per step. Power changes and adjusts automatically. Controllers can work with thyristor contactors or with conventional electromagnetic.

It is best to use thyristor contactors with controllers, as electronic switches are much more durable than electromagnetic switches, which need to be replaced frequently. There are no moving parts in them, so wear resistance is not a problem, and the switching speed is very high.

These advantages make it possible to collect such compensation schemes of thyristor contactors that the capacitors will be connected to the network strictly at the moment when the voltage in the capacitor is equal to the network voltage, that is, the current during switching will be almost zero.

The advantage of thyristor contactors in terms of speed and accuracy of operation is due to the fact that, in addition to the switch, they also include an electronic unit that allows safe switching of power steps up to 100 kVar, while there will be no interference in the network.

Thus, reactive power compensation controllers in combination with electronic contactors will allow switching capacitor stages at a speed of tens of times per second, and even rapidly changing reactive loads, such as powerful crane motors or welding machines, will not overload the enterprise network, wires they will not overheat, resource transformers will increase and the quality of consumed electricity will be high.