Ways to increase the current frequency

The most popular method of increasing (or decreasing) the frequency of current today is to use a frequency converter. Frequency converters make it possible to obtain from single-phase or three-phase alternating current with an industrial frequency (50 or 60 Hz) a current with the required frequency, for example from 1 to 800 Hz, to power single-phase or three-phase -phase motors.

Along with electronic frequency converters, in order to increase the current frequency, electric induction frequency converters are also used, in which, for example, an asynchronous motor with a wound rotor works partially in generator mode. There are also umformers — engine generators, which will also be discussed in this article.

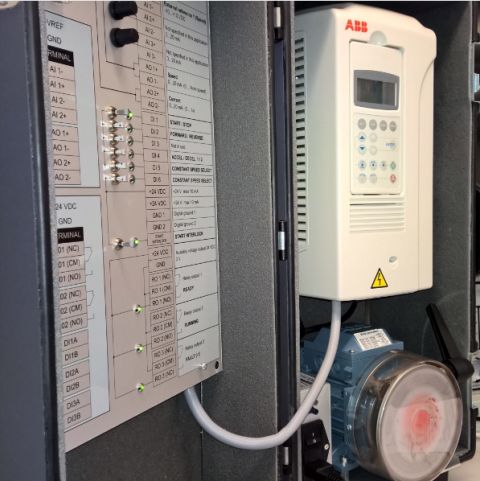

Electronic frequency converters

Electronic frequency converters allow you to smoothly control the speed of synchronous and asynchronous motors due to a smooth increase in the output frequency of the converter to the set value. The simplest approach is provided by setting a constant V / f characteristic, and more advanced solutions use vector control.

Frequency convertersusually include a rectifier that converts power-frequency alternating current to direct current; after the rectifier there is an inverter in its simplest form, based on PWM, which converts a constant voltage into an alternating load current, and the frequency and amplitude are already set by the user, and these parameters can differ from the network parameters of the input up or down.

The output module of an electronic frequency converter is most often a thyristor or transistor bridge consisting of four or six switches that form the necessary current to supply the load, in particular the electric motor. An EMC filter is added to the output to smooth the noise in the output voltage.

As mentioned above, an electronic frequency converter uses thyristors or transistors as switches for its operation. A microprocessor module is used to control the keys, which serves as a controller and at the same time performs a number of diagnostic and protective functions.

Meanwhile, frequency converters are still of two classes: direct-coupled and DC-coupled. When choosing between these two classes, the advantages and disadvantages of both types are weighed and the appropriateness of one or the other to solve an urgent problem is determined.

Direct communication

Direct-coupled converters are distinguished by the fact that they use a controlled rectifier, in which groups of thyristors sequentially, unlocking, switch the load, for example, the windings of the motor, directly to the supply network.

As a result, bits of grid voltage sine wave are obtained at the output, and the equivalent output frequency (for the motor) becomes less than the grid, within 60% of it, that is, from 0 to 36 Hz for a 60 Hz input.

Such characteristics do not allow to change the parameters of the equipment in the industry in a wide range, therefore the demand for these solutions is low. In addition, non-locking thyristors are difficult to control, the cost of the circuits becomes higher and there is a lot of noise at the output, compensators are needed, and as a result, the dimensions are high and the efficiency is low.

DC connection

Much better in this respect are frequency converters with a pronounced direct current connection, where first the alternating mains current is rectified, filtered and then again through a circuit of electronic switches it is converted to alternating current of the required frequency and amplitude. Here the frequency can be much higher. Of course, the double conversion somewhat reduces the efficiency, but the output frequency parameters simply match the user's requirements.

To obtain a pure sine wave on the motor windings, an inverter circuit is used, in which the voltage of the desired shape is obtained thanks to pulse width modulation (PWM)… The electronic switches here are lock-in thyristors or IGBT transistors.

Thyristors withstand large impulse currents, compared to transistors, which is why they are increasingly resorting to thyristor circuits, both in direct communication converters and in converters with an intermediate DC link, the efficiency is up to 98%.

For the sake of fairness, we note that electronic frequency converters for the power network are a non-linear load and generate higher harmonics in it, which deteriorates the power quality.

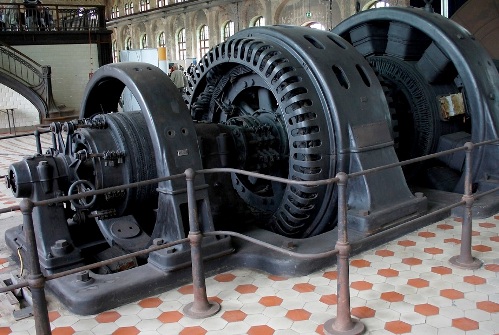

Motor generator (umformer)

In order to convert electricity from one of its forms to another, in particular, to increase the frequency of the current, without the need to resort to electronic solutions, so-called umformers — motor generators — are used. Such machines function as a conductor of electricity, but there is actually no direct conversion of electricity, such as in a transformer or in an electronic frequency converter, as such.

The following options are available here:

-

direct current can be converted into alternating current with a higher voltage and the required frequency;

-

direct current can be obtained from alternating current;

-

direct mechanical conversion of the frequency with its increase or decrease;

-

obtaining a three-phase current with the required frequency from a single-phase current at the mains frequency.

In its canonical form, a motor-generator is an electric motor whose shaft is directly connected to the generator. A stabilizing device is installed at the output of the generator to improve the frequency and amplitude parameters of the generated electricity.

In some models of umformers, the armature contains coils and a motor and generator which galvanically isolated, and whose wires are connected to the collector and to the output rings, respectively.

In other versions, there are common windings for both currents, for example, there is no collector with slip rings to convert the number of phases, but simply taps are made from the stator winding for each of the output phases.So an induction machine converts single-phase current to three-phase current (basically identical with increasing frequency).

So, the motor-generator allows you to transform the type of current, voltage, frequency, number of phases. Until the 70s, converters of this type were used in the military equipment of the USSR, where they powered, in particular, lamp devices. The single-phase and three-phase converters are supplied with a constant voltage of 27 volts, and the output is an alternating voltage of 127 volts 50 hertz single-phase or 36 volts 400 hertz three-phase.

The power of such transformers reaches 4.5 kVA. Similar machines are used in electric locomotives, where a direct voltage of 50 volts is converted to an alternating voltage of 220 volts with a frequency of up to 425 hertz to power fluorescent lamps and 127 volts 50 hertz to power passenger shavers. The first computers were often used by umformers to power them.

To this day, umformers can be found here and there: in trolleybuses, in trams, in electric trains, where they are installed to obtain a low voltage for powering control circuits. But now they have already been almost completely displaced by semiconductor solutions ( thyristors and transistors).

Motor-generator converters are valuable for a number of advantages. First, it is a reliable galvanic isolation of the output and input power circuits. Second, the output is the purest sine wave with no distortion, no noise. The device is very simple in design and therefore maintenance is quite resourceful.

This is an easy way to get three phase voltage. The inertia of the rotor smoothes the current spikes when the load parameters change abruptly.And of course, it's very easy to restore electricity here.

Not without its flaws. Umformers have moving parts and therefore their resource is limited. Mass, weight, abundance of materials and, as a result, a high price. Noisy work, vibrations. The need for frequent lubrication of bearings, cleaning of collectors, replacement of brushes. The efficiency is within 70%.

Despite the disadvantages, mechanical motor generators are still used in the electric power industry to convert large powers. In the future, motor generators may help match 60 and 50 Hz grids or provide grids with increased power quality requirements. Powering the rotor windings of the machine in this case is possible from a low-power solid-state frequency converter.