Electronic thermal relays for motor overload protection

What are thermal relays for?

Thermal relays are used to protect electric motors from overloading. Since overheating is a consequence of overcurrent, such a relay protects the motor from overcurrent as such and from overheating. That is, the use of a thermal relay is recommended in situations where the currents in the supply network and, accordingly, in the supplied load for some reason can exceed the permissible rating by up to 1.11 — 7 times, and then the relay setting will prevent the destruction of the equipment.

If the equipment is responsible for precise and responsible work, then it must be protected from overheating, otherwise damage will occur. In fact, the thermal relay will compare the effective value of the current flowing with the setting and protect the equipment if the setting is exceeded - after a strictly defined period of time the load circuit will be opened, the equipment will be saved.

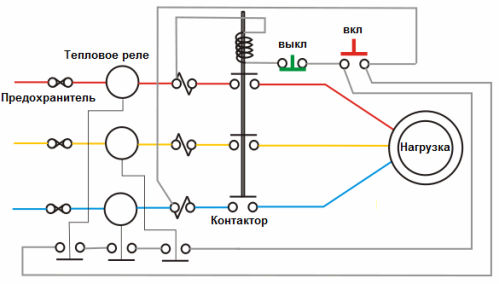

The power circuits are switched by contactors and then the thermal relay only controls the supply to the contactors and high current stability is not required from the relay itself. The relay in the form of an auxiliary unified unit is connected to the contactor, and the power contactor itself switches the load.

Relays usually have normally open and normally closed contacts, the former responsible for powering the signal lamp (for example) and the latter for powering the contactor.

When the temperature of the electrical equipment is within the established permissible limits, the thermal relay keeps the circuit closed, and as soon as an excess occurs, it turns off after a certain period of time, and the higher the ratio of the overload current to the nominal, the faster the relay is triggered, because the higher the current, the faster the wire heats up, and overheating of any part of the protected equipment must not be allowed.

Thermal relay parameters

At high overload values (several times), characteristic of a short circuit, the opening is carried out by a circuit breaker with an electromagnetic release or a fuse. In general, the causes of overload can be different, for example, a regular hard start of an electric motor or frequent on-off operations. Then the trigger will be false.

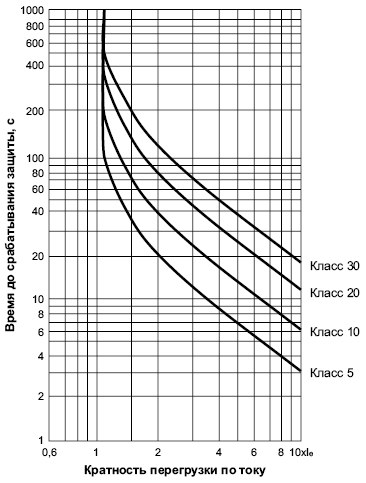

To exclude false alarms, the setting is set without reserves, the difference is only in the classes of the relays themselves from 5 to 40, indicating the response time: class 5 — 3 seconds with a tenfold overload, class 10 — 6 seconds with a tenfold overload, etc. ., determined at an ambient temperature of 20 ° C, with symmetrical three-phase operation, for overloading in a cold state. The setting shows the overload current and the class shows the maximum trip time in seconds.

An important characteristic of the thermal relay is the limit values of multiple long-term overloads — about an hour. This is the condition under which the relay is guaranteed to operate or fail to operate. So, if the threshold is set as 1.14 ± 0.06, then at 1.2 the relay is guaranteed to work, and at 1.06 it will definitely not work.

This parameter is extremely important, it determines the accuracy and reliability of the protection and also helps to prevent false alarms. The highest quality relays are temperature compensated to ensure constant operation at all ambient temperatures.

In accordance with the characteristics of the protected equipment, the response time of the thermal relay is also selected, taking into account the permissible overload speed. Large multiples—up to 10 times—require a more thorough approach. For example, class 10 is considered universal and is suitable for easy-start electric motors.

For heavy starts, class 20, class 30 or class 40 are more suitable. Class 5 — if high accuracy is required, for example, if the load is of low inertia.As a rule, manufacturers of thermal relays in the accompanying documentation indicate the most suitable equipment for which the class of this protective characteristic is currently the best.

The actual relay actuation time is important here, it must match the standard dependence. The best thermal relays with an overload of 3 to 7.2 times have a maximum trip time deviation from the standard of no more than 20% down and up. With an increase in temperature, for example due to preheating with rated current, the shutdown time is 2.5 to 4 times shorter than the standard at 20 ° C.

Disadvantages of simple thermal relays

Three-phase thermal relays are more versatile, they monitor currents in all three phases and are applicable to single-phase circuits, for alternating and direct current.

But if the phases are loaded highly asymmetrically? Then the temperature in one of the phases will rise faster and the equipment will dangerously overheat, because the effective value of the current of the three phases will not allow detection of danger. As a result, the tripping time and critical current of the thermal relay setting will actually be lower than the actual situation.

To solve the problem faster, a more modern thermal relay is needed, with integrated protection against phase current asymmetry. In such relays, in case of unbalance or in case of phase loss, the response time and current will change accordingly and the protection will remain reliable.

Thermal relays are usually made on the basis of bimetallic disconnectors. When heated by current, the plate bends and activates the shutdown mechanism, the relay is activated - it switches to the "off" state.When the plate cools, the mechanism will return to its original "on" state. The simplicity of the design of conventional relays impresses with their low cost and good noise insulation. But for thinner equipment, more accurate thermal relays — electronic ones — are needed.

Electronic thermal relays

Electronic non-volatile thermal relays, such as the Siemens 3RB20 and 3RB21 series, are equipped with built-in measuring systems for currents up to 630 A. These relays are independent of current and are able to protect loads in any mode, even with heavy starting, and with open or unbalanced phases.

In case of current overload, with a break in one of the phases or with an imbalance, the current, for example in the motor, increases and becomes higher than the setting. An integrated current transformer registers the current, and the electronics process the currently measured value, and if it exceeds the set value, a tripping pulse is transmitted to the circuit breaker, which disconnects the load by opening the external contactor. The relay itself is mounted on the contactor. The tripping time is strictly related to the ratio of the tripping current to the setting current.

The Siemens 3RB21 electronic thermal relay is not only able to protect against overheating due to phase asymmetry, overcurrent or phase loss, but also has an internal earth fault detection system (except for star-delta combinations). For example, incomplete earth faults due to insulation damage or moisture will be immediately detected and the load circuit will open.

When the relay is activated, the indicator will illuminate, signaling the tripping condition.Automatic reset or manual reset is possible. Automatic reset occurs after a set time, after which the relay will close the contactor again.