How desalination plants work and operate

One of the most effective methods of seawater desalination is reverse osmosis. Since the 1970s, reverse osmosis has been used to purify water for a variety of purposes, including the production of fresh water from salty seawater.

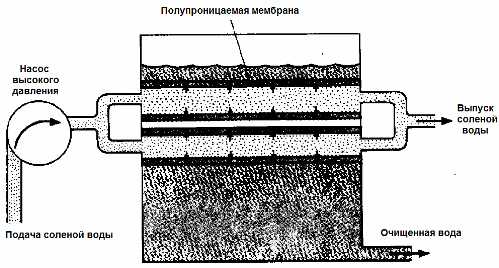

This technology involves a special type of filtration (ultrafiltration) of pressurized seawater through semi-permeable (reverse osmosis) membranes. These membranes transport seawater molecules through their micropores under pressure, but retain salt ions and other impurities. The pressure in such seawater desalination plants varies from 25 to 50 atm.

In industry today, reverse osmosis membranes for desalination plants are produced from cellulose acetate or polyamide in the form of rolls and fibers. In addition to membranes, reverse osmosis desalination plants include in their designs: high pressure pumps, fine water filters, chemical treatment systems, chemical scrubbers and filter module units.

Desalination tubes are made of porous material, lined inside with cellulose acetate film. This film also acts as a reverse osmosis membrane. Several of these pipes are installed in parallel in a desalination plant.

Seawater is pumped through the pipes (at a pressure of up to 100 bar) in a continuous flow. At the exit, two streams are obtained - demineralized water (the so-called permeate) and a concentrate with salts, which usually goes as production waste.

The volume of fresh water received in the installation for a certain period of time is proportional to the pressure generated by the pump. The characteristics of the diaphragms determine the maximum allowable working pressure.

If the pressure turns out to be too high, the membrane will simply clog with impurities or allow many dissolved salts to pass through; in extreme cases, the membrane can rupture. If the pressure is low, the desalination process will slow down.

The quality of seawater desalination and the operating speed of the membrane are related to various factors. First of all, with the total salt content in the incoming water, its salt composition, water temperature and operating pressure.

For example, if you desalinate ordinary salt water from a well at a pressure of 50 bar, then from 1 square meter of reverse osmosis membrane will be given to obtain about 0.7 tons of fresh water per day. Therefore, more powerful desalination plants (for tens and hundreds of cubic meters of water per day) use several pipes.

Reverse osmosis desalination plants have a number of advantages.Electricity costs are relatively low, the units are compact and easy to install and operate, and finally the operation of the unit is easy to automate. Control of the desalination plant can be fully automatic or semi-automatic.

During the operation of the unit, it is important to reduce the formation of salt deposits in the pipes; For this purpose, sedimental inhibitors are used. To remove deposits from the membranes, the aforementioned chemical washing device is used. The consumption of concentrate and permeate during water treatment is controlled by flow meters. The outlet water is assessed for salinity and pH level—with flow-through salinity meters and pH meters.