Polymer electrical insulating materials and their use

The word "polymer" comes from "monomer", replacing the prefix "mono" with the prefix "poly", meaning "many". The fact is that in the process of chemical synthesis, polymers are obtained from monomers: polyethylene — from ethylene, polystyrene — from styrene, polyvinyl chloride (PVC, polyvinyl chloride) — from vinyl chloride (vinyl chloride), etc.

So take it rubbers and rubbers, synthetic resins and textolites, varnishes and adhesives, fibers and plastics, sealants, putties, etc. Polymers are widely used as electrical insulating materials. These will be discussed further.

All polymeric materials used as electrical insulating materials can be easily divided into four types according to their characteristic physical characteristics: thermoplastics, thermosets, laminates, and plastics (plastics). Let's look at each type of polymer separately.

Thermoplastics

"Thermo" — heat, "layer" — sculpted.The bottom line is that even when heated, the structure of thermoplastics remains unchanged, it simply transforms their solid state into a soft, plastic one and is easy to process and recycle.

Exclusive representatives of thermoplastics: polyvinyl chloride, polyethylene, polystyrene, polypropylene, polyformaldehyde, polyamides, polyacrylates, fluoroplastics, etc.

From thermoplastic, when it has passed under the action of high temperature into a viscous flow state, you can mold products or similarly process thermoplastic waste. Thermoplastics are easily cast and extruded. In this case, there are no transformation reactions of thermoplastics, they can be repeatedly processed and shaped.

A typical representative of a thermoplastic product is PVC insulation tape. If you warm it a little, it will soften, but after cooling it will become quite thick again. PVC insulation tape has always been popular among electrical work professionals.

Reactoplasts

In contrast to pure thermoplastics, thermosetting plastics are polymers that, by thermal action, first pass into a viscous plastic state, and then into a solid insoluble and insoluble state.

If you try to remelt the hardened thermosetting plastic, it will no longer become the same viscosity, and if you continue to heat, it will irreversibly collapse. This happens because the processing of thermoreactives is accompanied by an irreversible chemical reaction, and if the product is formed, its further reformation is impossible.

Thermosetting plastics include: amino plastics, silicone plastics, phenolic plastics, epoxy plastics, urethane plastics, aniline plastics and others.Polyester and epoxy, carbide and phenol-formaldehyde resins are the basis of the most common thermosetting plastics. In general, thermosetting plastics are harder than thermoplastics and their products often contain fillers such as carbon black, chalk, fiberglass, etc.

An example of a special heat-set product is a heat-shrink tube or a heat-shrink sleeve. The radiation-treated polymer will shrink when heated, but you won't be able to peel it back. Such tubes are used to insulate electrical products and wires.

Laminated plastics

Laminates include a variety of materials, including fiber fillers and polymers impregnated with fillers and adhesives that turn individual sheets into dense multi-layered plastics.

Sheet electrical insulating materials are mainly made of laminated plastics, as it is convenient to make sheets of the required thickness and size, the required surface shape from them.

Bright representatives of laminated plastics - textolite, getinax, wood-laminated plastics, asbestos-laminated plastics, etc.

Getinax is based on bakelite and paper. A layer of Bakelite varnish is applied to the paper, then the paper is rolled in several layers, then sent under a high-pressure press at elevated temperatures.

The effect of heat on Bakelite transforms it into a new — insoluble and insoluble state — resulting in a durable, high-hardness sheet material with excellent electrical insulating properties. At the same time, the material is well cut, drilled, cut — easy to process.

Getinax is used to manufacture parts of various electrical products that need reliable insulation, for example insulating racks and washers. Replacing paper with fabric, we no longer get getinax, but textolite — a more durable, wear-resistant laminated plastic.

Textolite surpasses some metals in terms of frictional stability, it is no coincidence that gears of mechanisms are sometimes made from it. Fiberglass laminate is an even more durable material — the glass fabric makes it heat resistant.

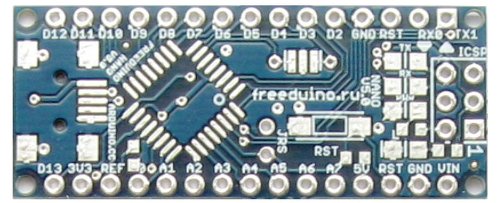

Fiberglass foil and getinax foil are traditionally used for the production of printed circuit boards of various electronic devices: on one or both sides oxidized copper foil is applied to such fiberglass (it is included in the process of forming laminated plastic at the pressing stage) with glue ).

For special applications, the foil can be nickel-plated or chrome-plated. When the PCB pattern is transferred to the foil layer, the unnecessary foil outside the pattern is etched away (eg with ferric chloride), leaving copper traces. The tracks are then insulated with solder mask, and the radio components are mounted on the board (soldered to the tracks).

Plastics

The next type of electrical insulating polymers are plastics (plastics, plastics). They are made of natural and synthetic polymers that determine their properties. In addition to the base polymer, plasticizer, filler, dye and stabilizer are added to the plastic.

The dielectric properties of the plastic, its heat resistance and moisture absorption are strongly influenced by the filler, which can be mineral or organic, powdered or fibrous, sheet or layered.

Examples of powder fillers: mica, carbon black, wood flour, graphite, quartz flour, talc, metal powder, etc. Examples of fibrous fillers: glass fibers, asbestos, cotton wool, paper shavings, sawdust, etc. Laminated: fiberglass, asbestos cloth, paper, cotton cloth, wood veneer, etc.

To give elasticity to the plastic, a plasticizer is added to it. Plasticizer increases elongation, decreases tensile strength. To get the desired color, the right decorative effect, dye is added. A stabilizer is needed so that the plastic retains its properties throughout the life of the product and is not degraded by heat or sunlight.

Often, plastics are produced only from polymer without adding anything: plexiglass, vinyl plastic (PVC plastic), polystyrene, polyethylene, etc. Often, plastics are pressed into molds under pressure at high temperatures and thus completely finished products are obtained.

When the product must, according to the designer's plan, contain some other part, for example, a metal nut or sleeve, then the part is simply pressed or embedded at the molding stage.

If the insulating material is needed by the user not in the form of a part, but simply as a consumable, then it is traditionally sold in the form of slabs, rolls or packed in containers.

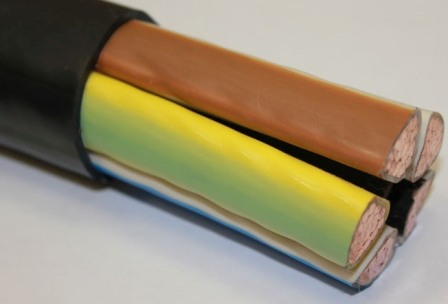

An example of plastic electrical insulation is the sheath of a VVG power cable used for the transmission and distribution of electricity.