5 most frequent failures of electromagnetic starters and methods of their elimination

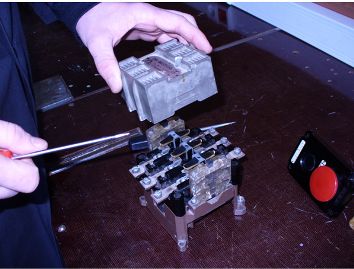

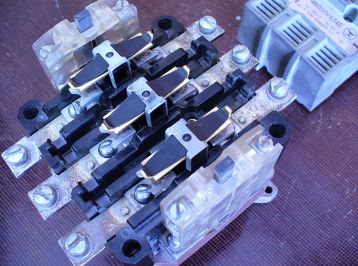

1. Closing time and status of main contacts

The time to close the main contacts magnetic starter can be removed by tightening the sleeve that holds the main contacts to the shaft. If there are traces of oxidation, sagging or hardened metal drops on the contacts, the contacts must be cleaned.

The time to close the main contacts magnetic starter can be removed by tightening the sleeve that holds the main contacts to the shaft. If there are traces of oxidation, sagging or hardened metal drops on the contacts, the contacts must be cleaned.

2. Loud buzzing of the magnetic system of the electromagnetic starter

Loud humming of the magnetic system can damage the starter coils. In normal operation, the starter makes only a faint noise. A loud starter hum indicates a malfunction.

To eliminate the hum, the starter must be disconnected and checked:

a) tightening the screws securing the armature and the core,

b) whether the short circuit embedded in the core sections is not damaged. As the coil flows alternating current, then the magnetic flux changes its direction and becomes zero at some moments of time.In this case, the opposing spring will pull the armature away from the core and armature bounce will occur. A short circuit eliminates this phenomenon.

c) the smoothness of the contact surface of the two halves of the electromagnetic system of the starter and the accuracy of their motors, since in electromagnetic starters the current in the coil strongly depends on the position of the armature. If there is a gap between the armature and the core, the current passing through the coil is greater than the rated current.

To check the accuracy of the contact between the armature and the core of the electromagnetic starter, you can put a sheet of carbon paper and a sheet of thin white paper between them and close the starter by hand. The contact surface must be at least 70% of the cross-section of the magnetic circuit. With a smaller contact surface, this defect can be eliminated by correctly installing the core of the electromagnetic system of the starter. If a common gap has formed, then it is necessary to scrape the surface along the layers of the steel sheet of the magnetic system.

3. Lack of reverse in reversible magnetic starters

The lack of reverse on reversing starters can be remedied by adjusting the mechanical locking rods

4. Gluing the anchor to the starter core

Sticking of the armature to the core occurs as a result of the absence of a non-magnetic spacer or its insufficient thickness. The starter motor may not stop even if the coil voltage is completely removed. Check for presence and thickness of non-magnetic seal or air gap.

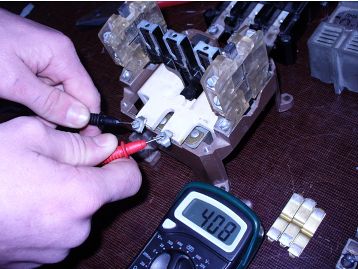

5. Starter does not self-lock when turned on

It is necessary to check the condition of the blocking contacts of the starter. The contacts in the on position must fit snugly together and turn on at the same time as the starter's main contacts. The distances of the auxiliary contacts (the shortest distance between an open moving and stationary contact) must not exceed the permissible values. It is necessary to adjust the auxiliary contacts of the starter. If the auxiliary contact damage becomes less than 2 mm, then the auxiliary contacts must be replaced.

Timely testing and adjustment of electromagnetic starters allows early avoidance of malfunctions and damage.