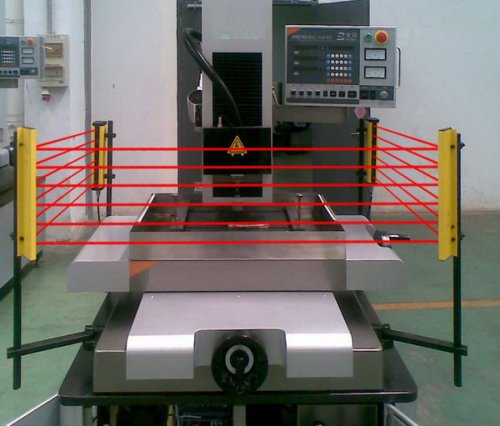

Optical barriers for safety

Optical safety barriers can be successfully used both in access control systems and as protective equipment for personnel in traumatic industries, for example, when working with a press, foundry, laser or other potentially dangerous equipment, including installations with chemically aggressive environments ...

In addition, optical barriers are used as part of systems to automatically control technological processes, such as the passage of pipes or metal sheets on rolling equipment, to avoid slipping or bouncing of large parts moving on a roller conveyor.

Basically, these barriers work as analog sensors consisting of a multi-beam emitter and receiver, capable of determining the size of objects or, in the simplest application, tracking the fact of potentially dangerous deviation of objects from their correct position during transport.

The emitter of the optical protective barrier contains several sources of infrared radiation, the parallel rays of which are directed to the corresponding points of the receiver. A series of parallel beams lying in the same plane are formed by infrared diodes mounted one above the other, the distance between which is usually 10 to 20 mm.

The emitter of the optical protective barrier contains several sources of infrared radiation, the parallel rays of which are directed to the corresponding points of the receiver. A series of parallel beams lying in the same plane are formed by infrared diodes mounted one above the other, the distance between which is usually 10 to 20 mm.

The receiver photodiodes are installed in the receiver in the same way. The entire device is fixed fixedly on the mounting brackets, while being precisely adjusted in height and position so that the rays from the emitter fall precisely on the corresponding photodiodes.

The standard sizes of optical barriers are different, they are produced at a height of 20 cm to 1 meter, and the receiver and the source of the rays can be separated by a distance of up to 10-20 meters from each other, depending on the model and purpose of a particular product .

The barrier is configured in accordance with its purpose. For example, if a person's hand accidentally passes through the barrier, the equipment shielded from its rays can automatically turn off or block only if the duration of penetration is more than 10 milliseconds, and if the duration of the object crossing the barrier is less, not shutdown occurs.

Some barrier models are able to generate an output signal, the value of which will be exactly proportional to the number of rays crossed at a given time — an indispensable possibility for estimating the amount of deviation of a part from a safe position. Also, in response to an output signal of any value in the room, an audible or light alarm can be activated.

In addition to the function of generating output signals that can be immediately processed controller or computer, optical safety barriers are often equipped with colored LED indicators.For example, if none of the optical barrier's rays are crossed by anything, then the indicator glows green. If at least one of the beams does not reach the receiver, the indicator lights up in red.

Today, when the era of high-precision CNC machines has arrived and robots have replaced humans in many production areas, the worker no longer has to stand behind the machine. In this sense, optical security barriers are truly indispensable, because they become an important factor in the safety and protection of a person who is ultimately assigned the role of administrator or personalization staff.

It is often required that an entire workshop or laboratory, a machine tool or an industrial robot be reliably fenced off with barriers so that a person's accidental entry into the work area does not disrupt the expensive production process, otherwise losses to the enterprise are inevitable.