Power transformer design

A transformer is an electrical machine that converts alternating current of one voltage to alternating current of another voltage.

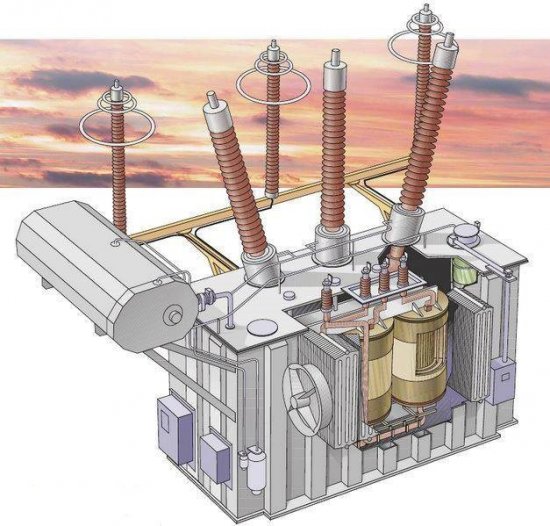

The main structural elements of power transformers: body, core, windings, cooling device, bushings and protective devices (expander, exhaust pipe and gas relay).

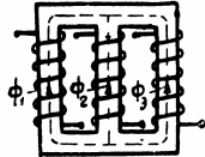

The windings of the transformer are arranged so that the magnetic flux created by the primary winding penetrates most of the secondary windings. This requirement is ensured by the construction of the steel core, which is a closed magnetic circuit. Depending on the mutual arrangement of the windings and the magnetic system, there are two main types of transformers: rod and armature.

In a rod transformer, the windings are located on the core rods, which are connected by yokes that close the magnetic circuit. The rod type is used for power supplies and a number of special transformers. An armored transformer uses a branched magnetic circuit that covers the winding, as if "armoring" it.The armor-like core structure is particularly used for small single-phase transformers.

Three-phase rod transformer:

The magnetic circuit of the transformer, called the core, is assembled from sheets of alloy steel. In order not to close the sheets, they are pre-coated with a thin layer of varnish or glued with paper.

The core consists of rods carrying coils and a yoke that closes the magnetic circuit. The cross-section of the core should be as close as possible to the shape of the coils.

In rectangular windings, the cross-section of the core is made rectangular. With round — the core has a multi-level section. If the core has a large cross-section, then longitudinal air channels are made to remove heat, dividing the core into separate packages.

Sheets are pulled together with pins or rivets. Individual sheets must not be connected to each other, as eddy currents may occur in the contact plane. To prevent the sheets from closing through the pins and rivets, insulating tubes are placed on them. The nuts and rivet heads are isolated from the core press plates with electrical cardboard washers.

Two types of windings are used in transformers: disc and cylindrical.

With a disk-shaped winding design, the primary and secondary windings are divided into a series of flat disk-shaped windings that alternate in series on the transformer core.

In a cylindrical winding, the primary and secondary windings are arranged concentrically to each other. The low voltage winding is usually placed closer to the core as it is easier to insulate it from the steel.

When making windings, a distinction must be made between the insulation of individual wires, the insulation between layers and windings, the insulation between the primary and secondary (secondary) windings, and the insulation of the windings relative to the core.

The windings of the transformer are made of copper wire covered with insulation. To insulate the winding wires, paper, sometimes cotton silk yarn, varnish (enamel) foil or several layers of insulation are used, for example, a layer of varnish and a layer of silk yarn, a layer of paper and a layer of cotton yarn, etc.

Paper separators are used as insulation between the layers. The windings are insulated with washers or electrical cardboard gaskets wrapped with oil-soaked tape, paper or canvas.

The ends of the transformer windings are brought out with the help of bushings, which isolate them from the grounded body (tank).

Transformer device:

There are two basic ways to connect the windings of a three-phase transformer: delta connection and star connection. When the windings are delta-connected, the phase voltage is equal to the line voltage, and the phase current is 1.73 times less than the line current. When the windings are star-connected, the phase voltage is 1.73 times less than the line voltage, and the phase current is equal to the line.

The method of connecting the windings in a three-phase transformer is of great importance, since the phase angle of the secondary voltage relative to the primary depends on it. The phase shift between the primary and secondary winding voltage also depends on the winding direction of the coils. For more details see here: Schemes and groups for connecting windings of power transformers

Where transformers are designed for joint parallel work, it is necessary that the instantaneous potentials of the phases of these transformers are the same. Transformers that have the same phase shift between the line voltages of the high and low voltage windings are assigned to the same group of winding connections, which are assigned a number in accordance with the hour designation.

To isolate the winding from the core and to isolate the high-voltage winding from the low-voltage winding, hard cylinders pressed from baked paper or cylinders made of electrical cardboard, so-called soft cylinders, are used.

In transformer construction, a special mineral (petroleum) oil is widely used, which is called transformer… The tanks are filled with transformer oil and a core with windings is immersed in it. This design is adopted for high power power transformers, for high power rectifier transformers, for high power pulse transformers.

Transformer oil, from which moisture and impurities have been removed, that is, dried and purified, is a good insulator between the windings and the metal case. In addition, transformer oil, which has a higher thermal conductivity than air, conducts heat well from the active parts of the transformer to the external surfaces of the tank.

As the power of the transformer increases, the losses grow faster than its geometric dimensions, which leads to the need to increase its cooling surface. See the details here: Cooling systems for power transformers

In practice, devices are used that convert alternating voltage, in which the primary and secondary windings are electrically connected. These devices are called autotransformers.

An autotransformer differs from a conventional transformer in that its primary and secondary windings are connected not only inductively (as in a conventional transformer), but also electrically.