Drilling and unfolding holes, tapping

Drilling holes

Holes in various products are drilled with drills, installed in drills, drills, clamps. Twist drills are most often used in plumbing, as they drill easily and provide a clean hole with more accurate dimensions.

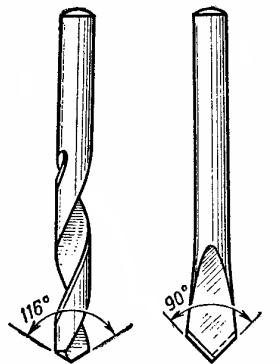

Impact drills are available in standard diameters with a sharpening angle (angle of the tip of the drill) mostly 116О... A drill with this sharpening angle is suitable for drilling in both hard and soft materials.

There is data on sharpening drills for metals of different hardness, but changing the angle of sharpening requires changing the shape of the chip removal grooves. Therefore, it is undesirable to change the angle of sharpening in twist drills, as this leads to rapid wear of the tool.

Planters are sharpened on special machines or manually on sandpaper. Correctness of sharpening is checked using a special template. For a well-sharpened drill, the cutting edges must be the same length and at the same angle to the axis of the drill.The center of the strip must be along the axis of the drill and form an angle of 55 with the cutting edge.O.

The angle of clearance when sharpening with a template is not checked, but it should be equal to 6O on the outer surface of the drill and increase to its axis to 20O... If these sharpening rules are not followed, the drill will hit, go to the side, take chips will heat up badly and quickly and the resulting hole will be irregular.

Drills (left - spiral, right - pen)

In the absence of twist drills of the required diameter or length, washer drills can be used. They are easy to make from carbon tool steel rod. For this purpose, a rod of the required dimensions is heated and flattened at one end in the form of a paddle.

This edge is hardened and then sharpened on sandpaper, so that cutting edges are formed on the tip of the drill at the desired sharpening angle. For drilling steel, the sharpening angle is assumed equal to 120°, for brass - 90°, for aluminum 80°.

To drill a hole, insert the selected drill until the chuck fails and tighten it slightly. Then check that the drill does not hit during rotation and tighten it in the chuck as much as possible.

Before starting drilling, it is necessary to deepen each center of the marked holes by re-punching, and then fix the product in a workbench vise so that it does not bend or move during the drilling process.

The drill, first you need to set perpendicular to the surface of the product, then slowly and carefully drill a small depression, check whether the drill coincides with the center of the punching.

If it has moved away from the center, then it is necessary to make a deeper drilling or to cut two or three radial channels from the center of the recess in the direction where the drill should be fed with a cross knife. In this case, the drill will pick up large chips where the channels are placed and move in the desired direction.

If an eccentricity is obtained this time, then it is necessary to make a new punch, drill a hole with a thin drill, and then with a drill of the required diameter. The pressure on the drill should be such as to ensure even chips. When the drill comes out of the metal, it is necessary to reduce the pressure, because at this point the drill catches large chips and can break.

When drilling deep holes, remove the bit more often and free it from stuck chips. In addition, to reduce the heating of the drill, it is necessary to apply drops of lubricant to the hole with a brush. This will result in a cleaner and more accurate hole.

Use mineral oil or soapy water when drilling steel, ductile iron, red copper, and brass, and soapy water and kerosene when drilling aluminum. Gray cast iron and bronze are drilled dry.

A large hole is drilled in two passages. First, the hole is drilled with a drill with a small diameter, and then with a drill of the required diameter. This method is due to the fact that smaller diameter drill bits are easier to install at the drilling point. In addition, the hole is more correct and more accurate.

Special care should be taken when using an electric drill with thin and long drill bits. In such cases, the worker should take a comfortable and stable position.The drill must be directed so that the axis of the drill coincides with the axis of the future hole.

It is recommended to finish drilling once without removing the drill from the hole and not tilting the drill to the side, as the slightest tilt of the drill will break the drill. In this case, very little power is needed, and if the planter is in a vertical position, then the feed of the drill is carried out by the weight of the own weight of the planter.

When drilling large and shaped holes in sheet metal, a series of small holes are pre-drilled side by side so that they almost reach the marking line. The gaps between these holes are cut with a cross knife, and the unevenness is cut with a file. Holes in cylindrical parts are drilled on a support with a cut recess.

Expanding holes

Reaming is the process of machining holes by flaring. Hole reaming is performed when assembling parts when a slightly larger hole or greater accuracy and cleanliness of its completion is required, for example, for calibrating the bore of bushings.

Manual cylindrical and conical expanders are used in plumbing. Manual spreaders have a large suction (working) part and their tail has a square for inserting a wrench.

Taper reamers are used to remove and straighten taper holes. It is also convenient to use conical reamers to expand the holes in the sheet material, in the chassis of the blocks. The unfolders are made in a set, three pieces in a set (rough, transition and finishing) or two (transition and finishing).

The expansion of the taper holes for countersunk heads of screws, screws and rivets is done by a taper countersink.

During manual operation, the unfolding must be turned with a knob, leaving it in the square hole of the knob.

Before using the unfolder, it is necessary to check all its cutters by touch and, if any irregularities are found, remove them. In order to obtain a hole of accurate dimensions, a hole is pre-drilled with a drill, the diameter of which is smaller than the required diameter of the hole by 0.2 — 0.4 mm, which ensures the supply of material for deployment.

The product is clamped in a vice so that the opening is in a vertical position. Then, the transition swing is left with the lower part in the hole and turned with a knob in the direction of the direction of the tip of the teeth. In order to obtain a hole with more accurate dimensions, a finishing after transient cleaning is used. It is necessary to turn the unfolder with pressure, go through the hole. You cannot rotate the swing in the opposite direction.

Thread cutting

In the repair business, threads are cut mostly by hand. Taps are used for cutting internal threads, and dies and screw boards for cutting external threads.

Locksmith kit:

Internal thread

According to the method of application, the cranes are divided into manual (locksmith) and machine.

Manual taps are produced in sets. The set includes three taps: coarse (first), medium (second) and finishing (third). All three taps are made so that the chip thickness cut by each tap is more or less the same. The third tap is used last to finish and calibrate the threads.

It is very important to choose the correct drill diameter for drilling threaded holes.

For cutting soft metals such as copper or aluminum, the diameter of the hole should be taken a little larger, because when cutting such metals are squeezed, which leads to jamming and chewing of the thread.

The thread is cut as follows: the product is clamped in a vise, and the end of the first tap is inserted into the hole as accurately as possible and pressed onto it with a button.

At the beginning of work, the crank is taken with the right hand, grasping the faucet with the thumb, middle and index finger, and with light pressure you slowly turn the faucet clockwise, keeping its vertical position. As soon as the faucet starts picking up the chips, they switch to a two-handed spin. After making one turn to the right, make a half turn to the left, etc. After passing the hole with the first tap, replace it with the second, and then with the third.

With a cutting length of up to 5 mm, only the first and third taps are released, and for cutting less precise threads it is enough to use the first two taps. When cutting deep holes, unscrew the tap more often and clean it with a brush of shavings and lubricate the cutting area with two or three drops of oil. Bronze and gray cast iron holes are dry cut.

External thread

Dies and screw boards are used for cutting external threads. Dies are circular (split and continuous). They are also called lerks. For work, the matrix is inserted into a special matrix with clamping screws.

Carving with round dies and screw boards is done in the same way as with taps. When cutting with dies, it is important that the diameter of the rod is slightly smaller than the outer diameter of the die cut.

The cutting bolt is fixed in a vise and slightly rounded on top with a file for better adhesion to the die. After lubricating the bolt with oil, put a die on top and, pressing hard on it, simultaneously turn the bench to the right. As soon as the die takes the chips, the die rotates in the same way as when working with a tap, that is, after each full revolution it makes a half revolution back. The thread is cut in one or two passes.