Bearings for electric motors: purpose, application and types

In the 21st century, electric motors are becoming more and more efficient, but the requirements for them are correspondingly stricter. Anyone who follows code knows that it is important to consider the quality and reliability of all engine components, especially the bearings. The design of the bearing greatly affects how reliably the engine works, how quickly it wears out and whether its performance is high.

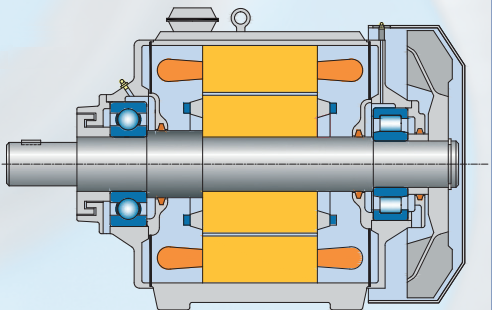

The bearing is one of the main units of any electric motor, because it is through it that the rotor shaft presses the housing and transfers the loads to it. And only thanks to the bearings there is an even and correct permanent air gap between the stator and the rotor when the motor is running under load.

For this reason, it is very important to choose the right bearings: they must be of the right size, type and design to ensure the highest possible efficiency by minimizing frictional losses.

To an inexperienced worker, it may seem that if a bearing fails, there is no serious problem and no repair or maintenance is necessary, since the failure is not so critical. So why spend money on repairs?

On low power engines this may be the case. But it will be true for any engine that it is better to immediately install good bearings of the most suitable type and if possible of sufficient quality to withstand all the working loads under normal operating conditions for the engine in question.

Needless to say about large powerful engines, where even a minor malfunction in the bearing can pull like a snowball, a number of problems and malfunctions in the operation of the connected equipment. This can lead to production interruptions and costly downtime of complex and expensive machinery and equipment.

Therefore, it is critical and necessary for high-powered electric motors to use reliable, high-quality bearings that are easy to install and remove, and highly desirable — with condition monitoring and easy maintenance.

Assume there is an electric motor operating in a direct coupled drive installation. The transmission configuration is longitudinal, so the radial load on the bearing and through the bearing on the motor housing is not so great because the motor drive system has its own support.

But what if the decision is made to retrofit a given motor on belt drive equipment where a pulley is mounted on the motor shaft? In this case, the radial loads on the bearings will increase significantly, and under such conditions, the bearings, which are not designed for such a load, can easily fail.The system will not be able to work normally and stably.

In recent years, the field of bearing development and production has not been spared from progress. The progress is particularly noticeable in the precision processing of bearing materials and bearing manufacturing technology, as well as in the direction of lubrication: the raceways of rings, rollers and balls have better surfaces today, which leads to a reduction in friction and therefore noise and to reducing energy losses.

The best lubricants make bearings really durable and engines more reliable and resistant to premature wear. A striking example is the traction motors of the latest high-speed electric trains.

Electric trains of the latest generation inherently place high demands on the quality and reliability of AC traction motors. And the newest camps excel here.

Severe operating conditions, significant impact and radial loads at the highest shaft speed. Trains run at high speed and service is infrequent. The fact of the high quality of modern bearings is obvious.

Bearings, especially in high-speed motors, suffer the most from electrical erosion. The reason for this destructive phenomenon is that stray currents pass through the bearing. The greater the current and the longer its exposure, the greater the damage to the bearing.

Sometimes electrical arcs cause erosion, resulting in small craters on the raceways and rolling elements, leading to premature bearing failure.

Ceramic rolling elements in the bearings, as well as a dielectric coating applied by plasma spraying, help to solve the problem of erosion. A sealing acrylic resin is applied to the ceramic layer. This is important for traction motors on high-speed trains. The resin protects the bearing from the harmful effects of steam and alkaline detergents used to wash the compositions.

Adequate relubrication is an important factor in extending the life of any bearing. The lubricant must penetrate sufficiently to the rolling elements.

Computational fluid dynamics (CFD) and finite element analysis help optimize lubricant distribution and maintain bearing strength. Of course, this will only help to extend the life of the assembly if the bearing is correctly selected for the operating load conditions of the engine in which it is installed.

Usually, in order to optimize the economic cost of bearing maintenance, the planned maintenance of all equipment is aligned with the maintenance schedule of other parts. To do this, if possible, they extend the lubrication intervals directly to the bearings of electric motors, using effective seals and the best methods of their lubrication.

See also on the website: Operation, maintenance and troubleshooting of electric motor bearings