Computer Cooling Systems: Passive, Active, Liquid, Freon, Water Cooler, Open Evaporation, Cascade, Peltier Cooling

During the operation of the computer, some of its components get very hot, and if the generated heat is not removed quickly enough, then the computer will simply not be able to work due to the violation of the normal characteristics of its main semiconductor components.

Removing heat from the heating parts of the computer is the most important task that the computer cooling system solves, which is a set of specialized tools that function continuously, systematically and harmoniously during the entire time that the computer is actively used.

During the operation of the computer cooling system, the heat generated by the passage of operating currents through the key elements of the computer, especially through the elements of its system unit, is utilized.The amount of heat generated in this case depends on the computing resources of the computer and its current load in relation to all the resources available to the machine.

In any case, the heat is recovered in the atmosphere. In passive cooling, the heat is removed from the heated parts through a radiator directly into the surrounding air by conventional convection and infrared radiation. In active cooling, in addition to convection and infrared radiation, blowing with a fan is used, which increases the intensity of convection (this solution is called a «cooler»).

There are also liquid cooling systems where the heat is first transferred by a heat carrier and then used again in the atmosphere. There are open evaporative systems where heat is removed due to the phase transition of the coolant.

So, according to the principle of removing heat from the heating parts of the computer, there are cooling systems: air cooling, liquid cooling, Freon, open evaporation and combined (based on Peltier elements and water coolers).

Passive air cooling system

Equipment that is not heat loaded does not require special cooling systems at all. Non-heat loaded equipment is one where the heat flux per square centimeter of the heated surface (heat flux density) does not exceed 0.5 mW. Under these conditions, the overheating of the heated surface relative to the surrounding air will not be higher than 0.5 ° C, the usual maximum for such a case is +60 ° C.

But if the thermal parameters of the components in the normal mode of their operation exceed these values (while keeping the heat generation, however, relatively low), then only radiators are installed on such components, that is, devices for passive heat removal, the so-called. passive cooling systems.

When the power of the chip is low, or when the computing capacity requirements of the system are constantly limited, as a rule, only a heatsink is sufficient, even without a fan. The radiator is selected individually in each case.

Basically, the passive cooling system works in the following way. The heat is transferred directly from the heating component (chip) to the heatsink due to the thermal conductivity of the material or with the help of heat pipes (thermosyphon or evaporation chamber are different fundamental solutions with heat pipes).

The function of the radiator is to radiate heat into the surrounding space through infrared radiation and transfer heat simply through the thermal conductivity of the surrounding air, which contributes to the occurrence of natural convection currents. In order to radiate heat over the entire area of the radiator as intensively as possible, the surface of the radiator becomes black.

Especially today (in various equipment, including computers), the passive cooling system is widespread. Such a system is very flexible, as radiators can be easily mounted on most heat-intensive components. The larger the effective area of heat dissipation from the radiator, the more efficient the cooling.

Important factors affecting the cooling efficiency are the speed of the air flow passing through the heatsink and the temperature (especially the temperature difference to the environment).

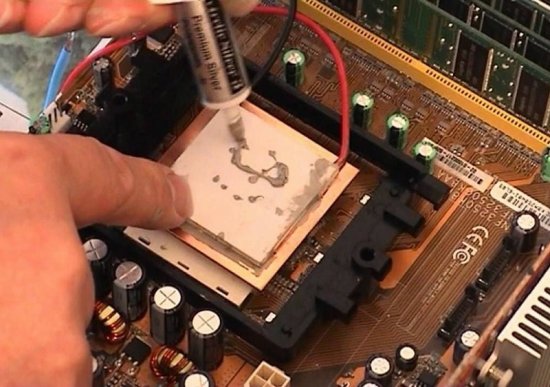

Many people know that before mounting a heatsink on a component, it is necessary to apply thermal paste (eg KPT-8) to the mating surfaces. This is done to increase thermal conductivity in the space between the components.

Initially, the problem is that the surfaces of the radiator and the component it is installed on, after factory production and grinding, still have roughness on the order of 10 microns, and even after polishing, about 5 microns of roughness remain. These irregularities prevent the connecting surfaces from being pressed together as tightly as possible without a gap, resulting in an air gap with low thermal conductivity.

Heatsinks with the largest size and active area are usually mounted on CPUs and GPUs. If it is necessary to assemble a silent computer, then, given the low speed of air passage, special very large radiators are needed, characterized by increased efficiency of heat dissipation.

Active air cooling system

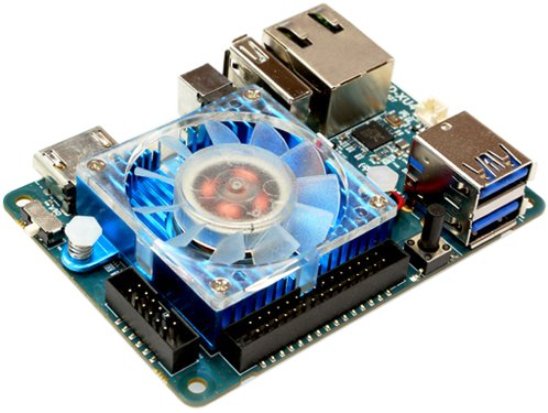

To improve cooling, to make the air flow through the radiator more intense, fans are additionally used. A radiator equipped with a fan is called a cooler. Coolers are installed on the graphics and central processors of the computer. If it is not possible to install a heatsink on some of the components, such as a hard drive, or it is not recommended, then a simple fan blowout without a heatsink is used.That's quite enough.

Liquid cooling system

The liquid cooling system works on the principle of transferring heat from the cooled component to the radiator with the help of a working fluid circulating in the system. Such a liquid is usually distilled water with bactericidal and anti-galvanic additives or antifreeze, oil, other special liquids, and in some cases liquid metal.

Such a system necessarily includes: a pump for circulating the fluid and a radiator (water block, cooling head) to take away the heat from the heating element and transfer it to the working fluid. The heat is then dissipated by a heatsink (active or passive system).

In addition, the liquid cooling system has a reservoir of working fluid, which compensates for its thermal expansion and increases the thermal inertia of the system. The tank is convenient to fill and it is also convenient to drain the working fluid through it. In such a system, the necessary hoses and pipes are required. A liquid flow sensor can be optionally available.

The working fluid has a sufficiently high heat capacity to provide high cooling efficiency at low circulation speed and high thermal conductivity, which minimizes the temperature difference between the evaporating surface and the pipe wall.

Freon cooling system

Extreme overclocking of the processor requires a negative temperature of the cooled element during its continuous operation. Freon installations are required for this. These systems are refrigeration units in which the evaporator is mounted directly on the component from which heat must be removed at a very high rate.

The disadvantages of the freon system, in addition to its complexity, are: the need for thermal insulation, the mandatory struggle with condensate, the difficulty in cooling several components at the same time, the high energy consumption and the high price.

Waterchiller

Waterchiller is a cooling system that combines a Freon unit and liquid cooling. Here, the antifreeze circulating in the system is further cooled in a heat exchanger using a Freon block.

In such a system, a negative temperature is obtained with the help of a freon unit, and the liquid can simultaneously cool several components. A conventional Freon cooling system does not allow this. The disadvantages of a water cooler are the need for thermal insulation of the entire system, as well as the complexity and high cost.

Open evaporative cooling system

Open vapor cooling systems use a working fluid—a refrigerant such as helium, liquid nitrogen, or dry ice. The working fluid is evaporated in an open glass, which is mounted directly on the heating element, which must be cooled very quickly.

This method belongs to amateurs and is mainly used by hobbyists who need extreme overclocking ("overclocking") of the available equipment. Using this method, you can get the lowest temperature, but the glass with the refrigerant will have to be replenished regularly, that is, the system has a time limit and requires constant attention.

Cascade cooling system

A cascade cooling system means the simultaneous sequential inclusion of two or more freons. To achieve lower temperatures, freon with a reduced boiling point is used.If the freon machine is single-stage, then it is necessary to increase the working pressure with powerful compressors.

But there is an alternative — cooling the radiator of a freon block with another similar block. Thus, the operating pressure in the system can be reduced and high power is no longer required from the compressors, conventional compressors can be used. The cascade system, despite its complexity, allows to achieve a lower temperature than with a conventional freon installation, and compared to an open evaporation system, such an installation can work continuously.

Peltier cooling system

In the cooling system with a Peltier element it is mounted with its cold side on the surface to be cooled, while the hot side of the element requires intensive cooling from another system during its operation. The system is relatively compact.