Electric gas cleaning - the physical basis of the operation of electrostatic precipitators

If you pass a dusty gas through the zone of action of a strong electric field, then theoretically dust particles acquire an electric charge and will begin to accelerate, moving along the lines of force of the electric field to the electrodes, followed by deposition on them.

However, under the conditions of a uniform electric field, it will not be possible to obtain impact ionization with the generation of mass ions, since in this case the destruction of the gap between the electrodes will certainly occur.

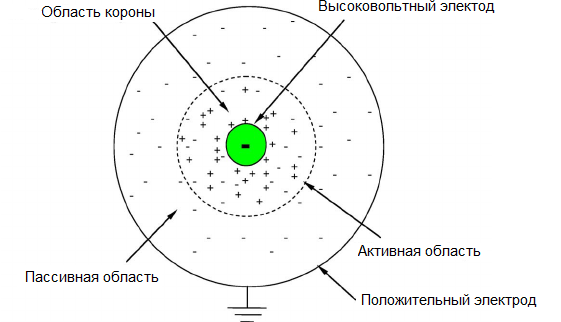

But if the electric field is inhomogeneous, then the impact ionization will not lead to the breakdown of the gap. This can be achieved, for example, by applying hollow cylindrical capacitor, near the central electrode, on which the electric field stress E will be much greater than near the outer cylindrical electrode.

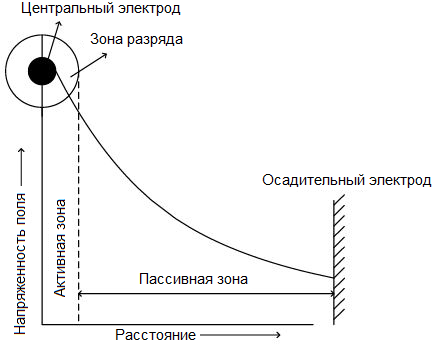

Near the central electrode, the electric field strength will be maximum, while moving away from it to the outer electrode, the strength E will first quickly and significantly decrease, and then continue to decrease, but more slowly.

By increasing the voltage applied to the electrodes, we first obtain a constant saturation current, and by further increasing the voltage, we will be able to observe an increase in the electric field strength at the central electrode to a critical value and the beginning of shock ionization near it.

As the voltage is further increased, the impact ionization will spread over an increasingly large area in the cylinder and the current in the gap between the electrodes will increase.

As a result, a corona discharge will occur, therefore ion generation will be sufficient to charge dust particles, although the final breaking of the gap will never happen.

To obtain a corona discharge in order to charge dust particles in a gas, not only a cylindrical capacitor is suitable, but also a different configuration of electrodes that can provide an inhomogeneous electric field between them.

For example, widespread electrofilters, in which an inhomogeneous electric field is produced using a series of discharge electrodes mounted between parallel plates.

The determination of the critical stress and the critical stress at which corona occurs is made due to the corresponding analytical dependencies.

In an inhomogeneous electric field, two regions with different degrees of inhomogeneity are formed between the electrodes. The corona region promotes the generation of opposite-sign ions and free electrons near the thin electrode.

Free electrons, along with negative ions, rush to the positive outer electrode, where they give it their negative charge.

The corona here is distinguished by a significant volume, and the main space between the electrodes is filled with free electrons and negatively charged ions.

In tubular electrostatic precipitators, the gas to be dedusted is passed through vertical tubes 20 to 30 cm in diameter, with 2 — 4 mm electrodes stretched along the central axes of the tubes. The tube is a collecting electrode, as the trapped dust settles on its inner surface.

A plate precipitator has a row of discharge electrodes centered between the plates, and the dust settles on the plates. When a dusty gas passes through such a precipitator, ions are absorbed on the dust particles and thus the particles are quickly charged. During charging, the dust particles are accelerated as they move towards the collecting electrode.

Determinants of the velocity of dust movement in the outer zone corona discharge are the interaction of the electric field with the particle charge and the aerodynamic wind force.

The force that causes dust particles to move toward the collecting electrode— Coulomb force of interaction of the charge of the particles with the electric field of the electrodes… As the particle moves toward the collecting electrode, the active coulomb force is balanced by the head drag force. The drift velocity of a particle to the collecting electrode can be calculated by equating these two forces.

The quality of particle deposition on the electrode is affected by such factors as: particle size, their speed, conductivity, humidity, temperature, quality of the electrode surface, etc.But the most important thing is the electrical resistance of the dust. The biggest resistance dust is divided into groups:

Dust with a specific electrical resistance of less than 104 Ohm * cm

When such a particle comes into contact with a positively charged collecting electrode, it immediately loses its negative charge, instantly acquiring a positive charge on the electrode. In this case, the particle can immediately be easily carried away from the electrode, and the cleaning efficiency will drop.

Dust with a specific electrical resistance of 104 to 1010 Ohm * cm.

Such dust settles well on the electrode, is easily shaken out of the pipe, the filter works very efficiently.

Dust with a specific electrical resistance of more than 1010 Ohm * cm.

Dust is not easily captured by the electrostatic precipitator. The precipitated particles are ejected very slowly, the layer of negatively charged particles on the electrode becomes thicker. The charged layer prevents the deposition of newly arriving particles. Cleaning efficiency decreases.

Dust with the highest electrical resistance — magnesite, gypsum, oxides of lead, zinc, etc. The higher the temperature, the more intensely the dust resistance increases first (due to evaporation of moisture), and then the resistance drops. By moistening the gas and adding to it some reagents (or particles of soot, coke), you can reduce the resistance of the dust.

Entering the filter, some of the dust may be picked up by the gas and carried away again, this depends on the gas velocity and the diameter of the collecting electrode. Secondary entrainment can be reduced by immediately rinsing the already entrapped dust with water.

Current-voltage characteristic of the filter is determined by some technological factors.The higher the temperature, the higher the corona current; however, the stable operating voltage of the filter decreases due to a decrease in the breakdown voltage. Higher humidity means lower corona current. Higher gas velocity means lower current.

The cleaner the gas — the higher the corona current, the dustier the gas — the lower the corona current. The bottom line is that the ions move more than 1000 times faster than the dust, so when the particles are charged, the corona current decreases and the more dust there is in the filter, the lower the corona current.

For extremely dusty conditions (Z1 25 to 35 g / m23) the corona current can drop to almost zero and the filter will stop working. This is called crown locking.

A locked corona results in a lack of ions to provide sufficient charge to the dust particles. Although the crown rarely locks completely, the electrostatic precipitator does not perform well in dusty environments.

In metallurgy, plate electrofilters are most often used, characterized by high efficiency, removing up to 99.9% of dust with low energy consumption.

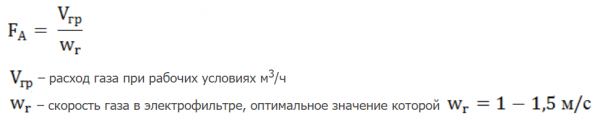

When calculating an electrofilter, its performance, efficiency of operation, energy consumption to create a corona, as well as the current of the electrodes are calculated. The performance of the filter is found by the area of its active section:

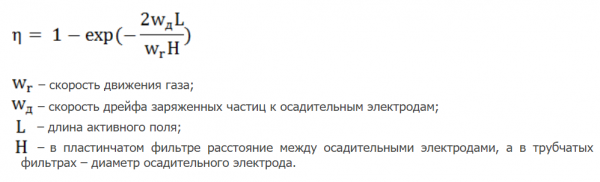

Knowing the area of the active section of the electrofilter, an appropriate filter design is selected using special tables. To find the filter efficiency, use the formula:

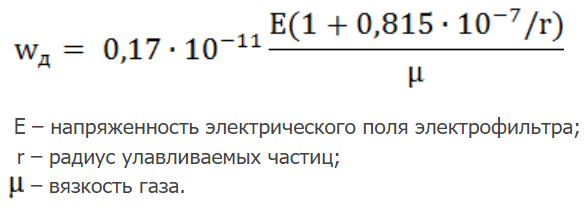

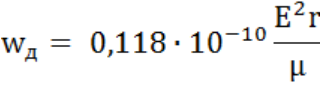

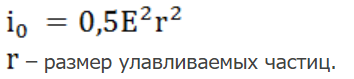

If the size of the dust particles is commensurate with the mean free path of the gas molecules (about 10-7m), then the speed of their deviation can be found by the formula:

The drift velocity of large aerosol particles is found by the formula:

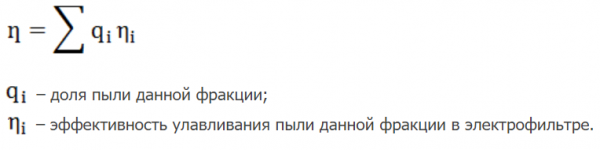

The efficiency of the filter for each dust fraction is produced separately, after which the overall efficiency of the electrostatic precipitator is established:

The operating intensity of the electric field in the filter depends on its construction, the distance between the electrodes, the radius of the corona electrodes and the mobility of ions. The usual operating voltage range for an electrofilter is from 15 * 104 to 30 * 104 V / m.

Friction losses are usually not calculated, but simply assumed to be 200 Pa. The energy consumption to create a corona is found by the formula:

The current when collecting metallurgical dust is established as follows:

The interelectrode distance of the electrofilter depends on its design. The length of the collecting electrodes is chosen depending on the required degree of dust collection.

Electrostatic precipitators are generally not used to capture dust from clean dielectrics and clean conductors. The problem is that highly conductive particles are easily charged, but they are also quickly ejected at the collecting electrode and are therefore immediately removed from the gas stream.

Dielectric particles settle on the collecting electrode, reduce its charge and lead to the formation of reverse corona, which prevents the filter from working properly. The normal operating dust content for the electrostatic precipitator is below 60 g / m23, and the maximum temperature at which electrostatic precipitators are used is +400 ° C.

See also on this topic:

Electrostatic filters — device, principle of operation, areas of application