Thermoelectric materials and methods for their preparation

Thermoelectric materials include chemical compounds and metal alloys, which are more or less pronounced. thermoelectric properties.

Depending on the value of the obtained thermo-EMF, on the melting point, on the mechanical characteristics, as well as on the electrical conductivity, these materials are used in industry for three purposes: for the conversion of heat into electricity, for thermoelectric cooling (heat transfer when passing electric current) and also to measure temperature (in pyrometry). Most of them are: sulfides, carbides, oxides, phosphides, selenides and tellurides.

So in thermoelectric refrigerators they use bismuth telluride... Silicon carbide is more suitable for measuring temperatures and c thermoelectric generators (TEG) A number of materials have been found to be useful: bismuth telluride, germanium telluride, antimony telluride, lead telluride, gadolinium selenide, antimony selenide, bismuth selenide, samarium monosulfide, magnesium silicide, and magnesium stannite.

The useful properties of these materials are based on on two effects — Seebeck and Peltier… The Seebeck effect consists in the appearance of thermo-EMF at the ends of series-connected different wires, the contacts between which are at different temperatures.

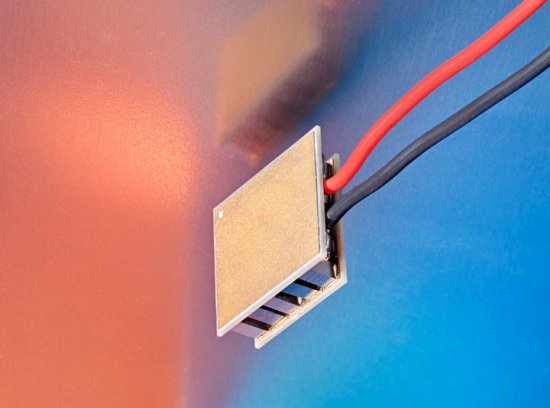

The Peltier effect is the opposite of the Seebeck effect and consists in the transfer of heat energy when an electric current passes through the contact points (junctions) of different conductors, from one conductor to another.

To some extent these effects are one since the cause of the two thermoelectric phenomena is related to a disturbance of the thermal equilibrium in the carrier flow.

Next, let's look at one of the most popular and sought-after thermoelectric materials — bismuth telluride.

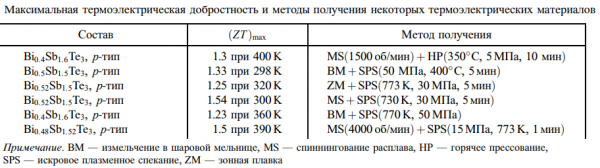

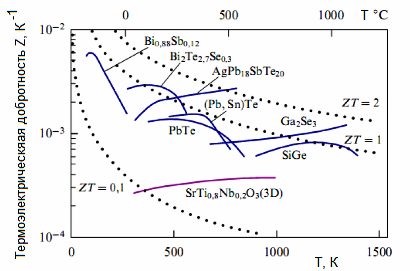

It is generally accepted that materials with an operating temperature range below 300 K are classified as low-temperature thermoelectric materials. A striking example of such a material is simply bismuth telluride Bi2Te3. On its basis, many thermoelectric compounds with different characteristics are obtained.

Bismuth telluride has a rhombohedral crystallographic structure that includes a set of layers—quintets—at right angles to the third-order symmetry axis.

The Bi-Te chemical bond is assumed to be covalent and the Te-Te bond is Waanderwal. In order to obtain a certain type of conductivity (electron or hole), an excess of bismuth, tellurium is introduced into the starting material or the substance is alloyed with impurities such as arsenic, tin, antimony or lead (acceptors) or donors: CuBr, Bi2Te3CuI, B, AgI .

Impurities give a highly anisotropic diffusion, its speed in the direction of the cleavage plane reaches the speed of diffusion in liquids.Under the influence of a temperature gradient and an electric field, movement of impurity ions in bismuth telluride is observed.

To obtain single crystals, they are grown by the directional crystallization (Bridgeman) method, the Czochralski method, or zone melting. Alloys based on bismuth telluride are characterized by pronounced anisotropy of crystal growth: the growth rate along the cleavage plane significantly exceeds the growth rate in the direction perpendicular to this plane.

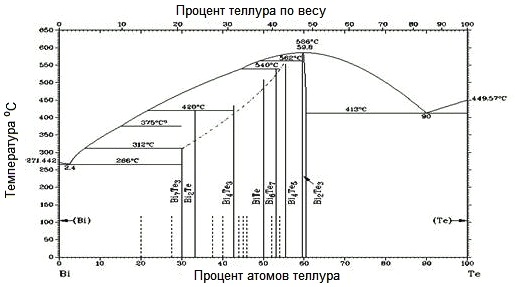

Thermocouples are produced by pressing, extrusion or continuous casting, while thermoelectric films are traditionally produced by vacuum deposition. The phase diagram for bismuth telluride is shown below:

The higher the temperature, the lower the thermoelectric value of the alloy, since the internal conductivity begins to affect. Therefore, at high temperatures, above 500-600 K, this glory cannot be used simply because of the small width of the forbidden zone.

In order for the thermoelectric value of Z to be maximal even at not very high temperatures, alloying is done as well as possible so that the impurity concentration is smaller, which would ensure lower electrical conductivity.

To prevent supercooling of the concentration (reduction of the thermoelectric value) in the process of growing a single crystal, significant temperature gradients (up to 250 K / cm) and a low speed of crystal growth — about 0.07 mm / min — are used.

Bismuth and alloys of bismuth with antimony on crystallization give a rhombohedral lattice that belongs to the dihedral scalenehedron.The unit cell of bismuth is shaped like a rhombohedron with edges 4.74 angstroms long.

The atoms in such a lattice are arranged in double layers, with each atom having three neighbors in a double layer and three in an adjacent layer. The bonds are covalent within the bilayer, and van der Waals bonds between the layers, resulting in a sharp anisotropy of the physical properties of the resulting materials.

Bismuth single crystals are easily grown by zonal recrystallization, Bridgman and Czochralski methods. Antimony with bismuth gives a continuous series of solid solutions.

A bismuth-antimony alloy single crystal is grown taking into account the technological features caused by a significant difference between the solidus and liquidus lines. So the melt can give a mosaic structure due to the transition to a supercooled state at the crystallization front.

To prevent hypothermia, they resort to a large temperature gradient — about 20 K / cm and a low growth rate — no more than 0.3 mm / h.

The peculiarity of the spectrum of current carriers in bismuth is that the conduction and valence bands are quite close. In addition, the change in spectrum parameters is affected by: pressure, magnetic field, impurities, temperature changes and the composition of the alloy itself.

In this way, the parameters of the spectrum of current carriers in the material can be controlled, which makes it possible to obtain a material with optimal properties and maximum thermoelectric value.

See also:Peltier element - how it works and how to check and connect