Permanent magnet magnetic field shielding, alternating magnetic field shielding

To reduce the magnetic field strength of a permanent magnet or a low-frequency alternating magnetic field with alternating currents in a certain region of space, use magnetic shielding… Compared to an electric field, which is quite easily shielded by the application Faraday cells, the magnetic field cannot be completely screened, it can only be weakened to some extent at a certain location.

In practice, for the purposes of scientific research, in medicine, in geology, in some technical fields related to space and nuclear energy, very weak magnetic fields are often shielded, induction which rarely exceeds 1 nT.

We are talking about both permanent magnetic fields and variable magnetic fields over a wide frequency range. Earth's magnetic field induction, for example, does not exceed 50 μT on average; such a field, along with high-frequency noise, is easier to attenuate by magnetic shielding.

When it comes to shielding stray magnetic fields in power electronics and electrical engineering (permanent magnets, transformers, high current circuits), it is often enough to simply localize a significant part of the magnetic field rather than trying to eliminate it completely. Ferromagnetic shield — for shielding permanent and low-frequency magnetic fields

The first and easiest way to protect the magnetic field is the use of a ferromagnetic shield (body) in the form of a cylinder, sheet or sphere. The material of such a shell must have high magnetic permeability and low coercive force.

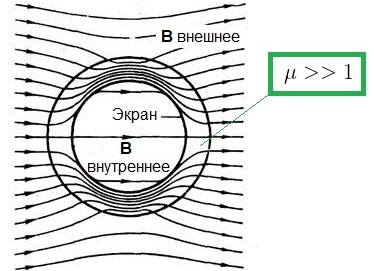

When such a shield is placed in an external magnetic field, the magnetic induction in the ferromagnet of the shield itself turns out to be stronger than inside the shielded area, where the induction will be correspondingly lower.

Let's consider an example of a screen in the form of a hollow cylinder.

The figure shows that the induction lines of the external magnetic field penetrating the wall of the ferromagnetic screen are thickened inside it and directly in the cylinder cavity, therefore the induction lines will be more rarefied. That is, the magnetic field inside the cylinder will remain minimal. For the high-quality performance of the required effect, ferromagnetic materials with high magnetic permeability are used, such as permaloid or mu-metal.

By the way, simply thickening the wall of the screen is not the best way to improve its quality.Much more effective are multilayer ferromagnetic shields with gaps between the layers making up the shield, where the shielding coefficient will be equal to the product of the shielding coefficients for the individual layers — the shielding quality of a multilayer shield will be better than the effect of a continuous layer with thickness equal to the sum of the upper layers.

Thanks to the multi-layered ferromagnetic screens, it is possible to create magnetically shielded rooms for various studies. The outer layers of such screens are made in this case of ferromagnets, which saturate at high values of induction, while their inner layers are of mu metal, permaloid, metglass, etc. — from ferromagnets that saturate at lower values of magnetic induction.

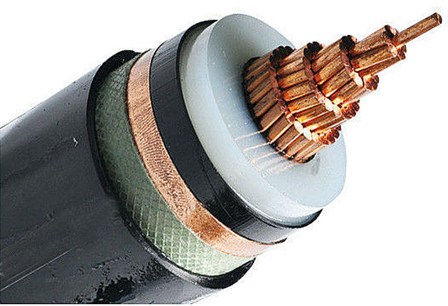

Copper shield — to shield alternating magnetic fields

If it is necessary to shield an alternating magnetic field, then materials with high electrical conductivity are used, such as honey.

In this case, the changing external magnetic field will induce induction currents in the conductive screen, which will cover the space of the protected volume, and the direction of the magnetic fields of these induction currents in the screen will be opposite to the external magnetic field, the protection from which is thus arranged. Therefore, the external magnetic field will be partially compensated.

In addition, the higher the frequency of the currents, the higher the shielding coefficient. Accordingly, for lower frequencies and even more so for constant magnetic fields, ferromagnetic screens are most suitable.

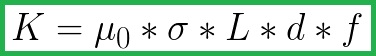

The sieving coefficient K, depending on the frequency of the alternating magnetic field f, the size of the screen L, the conductivity of the sieve material and its thickness d, can be approximately found by the formula:

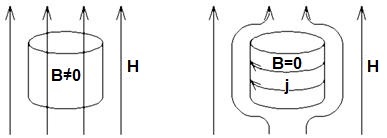

Application of superconducting screens

As you know, a superconductor is able to completely shift the magnetic field away from itself. This phenomenon is known as Meissner effect… According to Lenz's rule, any change in the magnetic field in the superconductor generates induction currents which, with their magnetic fields, compensate for the change in the magnetic field in the superconductor.

If we compare it with an ordinary conductor, then in a superconductor the induction currents do not weaken and therefore are able to exert a compensating magnetic effect for an infinitely (theoretically) long time.

The disadvantages of the method can be considered its high cost, the presence of a residual magnetic field inside the screen that was there before the transition of the material to a superconducting state, as well as the sensitivity of the superconductor to temperature. In this case, the critical magnetic induction for superconductors can reach tens of tesla.

Shielding method with active compensation

In order to reduce the external magnetic field, an additional magnetic field equal in magnitude but opposite in direction to the external magnetic field from which a certain area is to be shielded can be specifically created.

This is achieved through implementation special compensating coils (Helmholtz coils) — a pair of identical coaxially arranged current-carrying coils that are separated by a distance of the coil radius. A fairly uniform magnetic field is obtained between such coils.

To achieve compensation for the entire volume of a given area, you need at least six such coils (three pairs), which are placed in accordance with a specific task.

Typical applications for such a compensation system are protection against low-frequency disturbances generated by electrical networks (50 Hz), as well as shielding of the earth's magnetic field.

Typically, systems of this type work in conjunction with magnetic field sensors. Unlike magnetic shields, which reduce the magnetic field along with the noise in the entire volume bounded by the shield, active protection using compensation coils allows to eliminate magnetic disturbances only in the local area to which it is tuned.

Regardless of the design of the anti-magnetic interference system, each of them needs anti-vibration protection, since the vibrations of the screen and sensor contribute to the generation of additional magnetic interference from the vibrating screen itself.