Zinc oxide varistors for surge arresters

Zinc oxide varistors are semiconductor products with symmetrical non-linear current-voltage (CVC) characteristics. Such varistors are the most widely used. in surge protectors (SPN), especially for the protection of electrical equipment from lightning and switching surges. About the parameters and characteristics of this equipment — in the article published below.

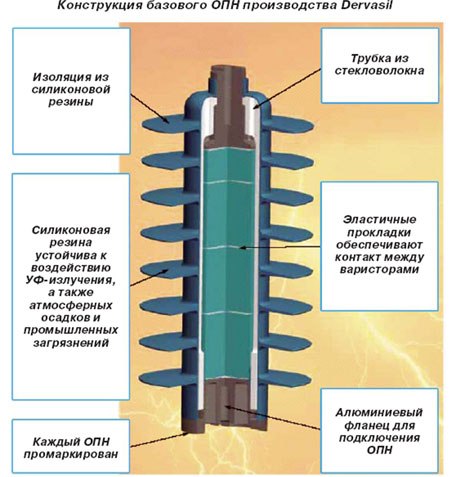

Zinc Oxide Varistor (OZV) is the main working element of the design of a non-linear surge arrester (SPD), therefore, increased stability requirements are imposed on the electrical characteristics of the varistor under various influencing factors.

So varistors must be resistant to aging when exposed to continuous operating voltage, be able to dissipate the released energy during the passage of certain current pulses, and limit the voltage to a safe value in the event of overvoltages.

Research and development in the development of varistors for limiters based on zinc oxide began as early as the 1980s in the Protection Devices Department of the All-Russian Electrotechnical Institute.

main parameters

Surge limiter non-linear — an electrical device designed to protect the insulation of electrical equipment from lightning and switching surges.

The advantage of these devices is that there are no sparks in them. Such devices can limit both lightning and switching surges in electrical installations of any voltage class and are very reliable.

The surge arrester is a column of series-connected single varistors, and its main parameters are simultaneously the parameters of highly nonlinear varistors.

Zinc oxide varistors, which are the main element of surge arresters, have high requirements for the stability of the current-voltage characteristic. Due to the fact that varistors are constantly under voltage, they also have high requirements for thermal stability.

One of the most important parameters is residual stress, which is defined as the maximum voltage value of the limiter (varistor) when current pulses of a given amplitude and shape pass through it.

For clarity, it is customary to work with relative values, i.e. to consider the residual voltages relative to the residual voltage at a given current pulse (for example, at a current pulse of 500 A, 8/20 μs).

Another important parameter that characterizes the ability of an arrester to absorb the switching energy of surges without damage is throughputthe ability of varistors to repeatedly (usually 18-20 times) withstand current pulses of a certain amplitude and duration (usually 2000 μs) without breaking and changing their characteristics.

Throughput is the manufacturer's specified maximum value of a rectangular current pulse of 2000 μs duration (throughput current). The arrester must withstand 18 such influences with the accepted sequence of their application without loss of performance. Surge arresters are divided into classes according to their capacity. The specific pulse energy corresponds to each class.

Finally, an important feature of modern zinc oxide varistors is stability under prolonged exposure to alternating voltage.

During the accelerated aging tests, the varistors should have a decreasing dependence of power losses in the varistors (P) on the exposure time (t) of the alternating voltage at elevated temperature. Such "non-aging" varistors allow a longer service life under the same conditions compared to limiters that use "aging" varistors.

Manufacture of varistors

Varistors have a non-linear current-voltage characteristic due to the semiconducting properties of the material from which they are composed. These properties are determined by the features of the microstructure of the varistor and the chemical composition of its material.

Even a small change in the ratio of the elements that make up the material of the varistor, or the addition of a small amount of new impurities, can lead to a significant change in its current-voltage characteristic and other electrical parameters.

The microstructure and electrical characteristics of varistors are also affected by changes in the varistor manufacturing process. In order to obtain high-quality varistors, the stability of all indicators of the technological process of their production is extremely important.

Zinc oxide varistors are manufactured using ceramic technology. However, there are a number of characteristics due to the fact that in semiconductor ceramics the electrical properties are determined not by the main component of the microstructure (crystallites), but by the intercrystalline boundaries. Therefore, in the production of nonlinear semiconductors using ceramic technology, two main tasks are set.

First, it is necessary to ensure a dense structure of the baked material with minimal porosity. Second, it is necessary to create an intergranular barrier layer.

A barrier layer is a contact between two adjacent crystallites whose surfaces contain localized electronic states created by doping and adsorption. Therefore, varistor technology must meet a number of specific requirements for purity, dispersion of source materials and powder mixing regime. Powders with a basic substance content of at least 99.0 — 99.8% are used as starting materials.

The charge (a mixture of starting materials) consists mainly of zinc oxide with the addition of various metal oxides. Homogenization and mixing of charged materials with distilled water is carried out in dispersing mills and spherical drums.

At a given slip concentration, its viscosity is controlled by a viscometer.Slurry drying and granulation are carried out in a spray dryer, at the optimum operating mode, from which granules of the press powder in the range of 50 - 150 microns are obtained. At this stage, the granule size, moisture content and flowability of the powder are controlled. The varistors are pressed using a hydraulic press.

Presses must meet certain requirements for density, dimensions and plane parallelism. Pressed pieces undergo a preliminary firing to remove the binder and a final firing during which potential barriers and an intermediate phase are formed.

Firing is done in chamber furnaces. After the final firing, the parts are ground, metallization is applied to the end surface, and a special coating is applied to the side surface.