Burner control units Kromschroder BCU series

Kromschroder burner controls of the BCU series are used in burners operating in continuous or intermittent operation.

In a small case there is a combustion control unit, a transformer, a display to show the modes of operation and errors. On request, the units can also be equipped with a valve check system, a high temperature control circuit.

Kromschroder combustion control units of BCU 4, BCY 370, BCU 560, BCU 565, BCU 570, BCU 580 are used in the metallurgical, food, ceramic, petroleum industries.

Kromschroder BCUs are installed in close proximity to the monitored burner.

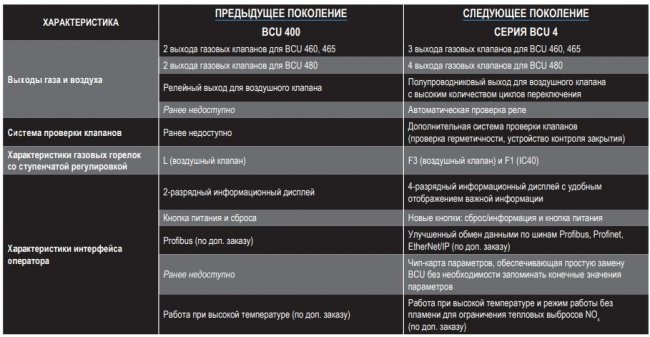

The new generation of controllers has a number of improvements over the old version.

The airflow control function in the controller controls the oven for cooling, blowing and power control. For stepwise or smooth burner power control, the machine has an interface through which an air valve or servo drive can be controlled.

Program status, operating parameters, error codes, flame signal level can be viewed using a four-digit display.

The additional valve control function allows you to check the valves for leaks by interrogating the gas pressure switch or checking that the valve is in the «Closed» position

Additional function of high temperature control mode and low NOx mode. In high temperature control mode, the controller can control the flame indirectly through temperature. In the mode of reducing nitrogen oxide emissions, a significant reduction in the formation of thermal nitrogen oxides is ensured.

The optical adapter allows diagnostic information to be read from the BCU using the BCSoft program. (With the help of the program it is possible to adjust the parameters of the device to bring them into line with the operational requirements. BCSoft saves and archives the parameters of the controller). The parameters are stored on an internal chip card. When replacing an old controller with a new chip, the parameterization card is removed and inserted into the new controller.

The BCU can be connected to PROFIBUS, PROFINET or EtherNet / IP.

Usage examples:

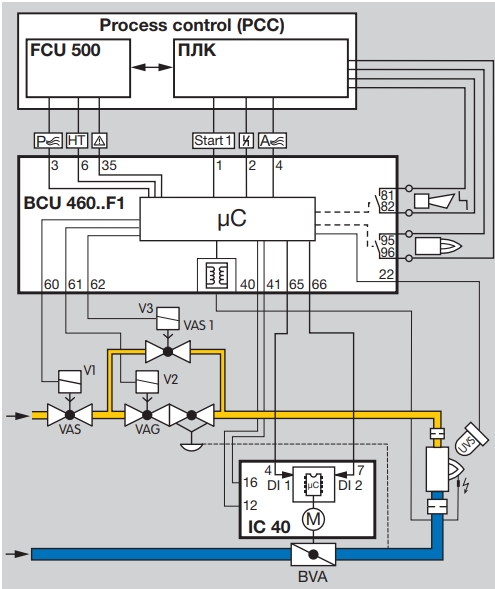

1) Industrial single stage burner

The air-gas mixture is adjusted according to operational requirements using programmable air prediction and air valve operation time. The pressure switch monitors the air flow in the air supply pipe or the flue gas outlet.

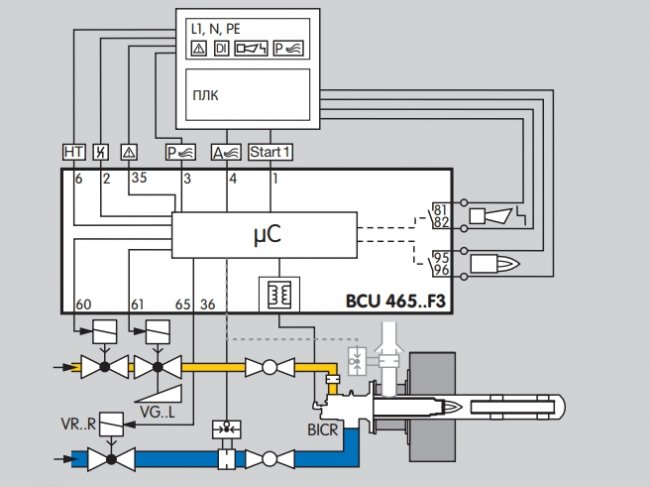

2) Step-by-step control of the burner

BCU starts purging. The DI 2 input is activated via the BCU terminal 66 output and moves the BVA throttle to the pre-purge position.To reach the set temperature, the burner control unit BCU activates input DI 1 via the output of terminal 65 and moves the throttle valve to the ignition position.

How the temperature control flame function works:

In high temperature gas installations (temperature > 750 °C) the flame can be controlled indirectly by temperature. As long as the furnace temperature is less than 750 °C, the flame must be controlled using conventional methods. If the temperature in the furnace rises above the self-ignition temperature of the gas-air mixture (> 750 ° C), the machine switches to high-temperature control mode.

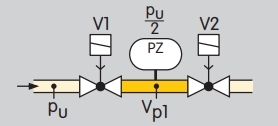

Valve density control function:

This function detects a leak in one of the gas shut-off valves and prevents the burner from starting. The solenoid gas valves V1 and V2 and the piping between the valves are checked. Upon successful completion of the test, the burner ignites.

The following modifications of BCU combustion controllers are most often used.

Code BCU 460-5 / 1LW3GB 84630361, BCU370WFEU0D1-3 code 88600369, BCU560WC0F1U0D1K1-E Code 88670723, BCU570WC1F1u0k2e Code 8

The BCU series controllers are used together with the following Kromschroder equipment: gas valves (VAS series), flame detectors (UVS and UVC series), automatic combustion regulators (PFU, IFW, IFD, IFS series), pressure switches (series DL-E , DL-A and DG).