Digital measuring devices: advantages and disadvantages, principle of operation

Digital measurement is one of the most revolutionary ways to measure various physical quantities throughout the history of mankind. We can say that in general, since the advent of digital technology, the importance of this type of device has largely determined the future of our entire existence.

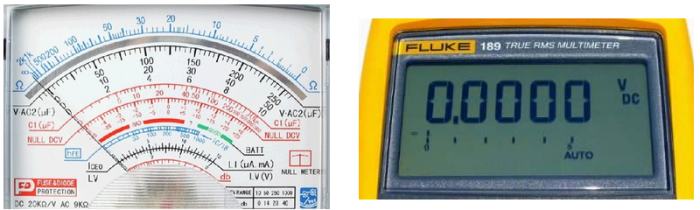

All measuring devices are divided into analog and digital.

Digital meters have a high response speed and a high class of accuracy. They are used to measure a wide range of electrical and non-electrical quantities.

Unlike digital analog devices, they do not store measured data and are not compatible with digital microprocessor devices. For this reason, it is necessary to record every measurement made with it, which can be tedious and time-consuming.

The main disadvantage of digital meters is that they need an external power source or battery charging after a certain time.Also, the accuracy, speed, and efficiency of digital devices make them more expensive than analog devices.

Digital measuring devices — devices in which the measured input analog value X is automatically compared empirically with discrete values of the known (sample) value N and the measurement results are given in digital form (How are analog, discrete, and digital signals different?).

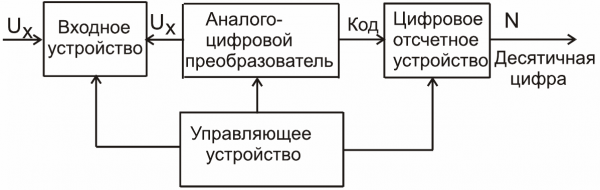

Block diagram of a digital voltmeter

When performing comparative operations in digital measuring instruments, the level and time of the values of the continuous measured quantities are quantized. The measurement result (numerical equivalent of the measured value) is formed after performing digital coding operations and is presented in a selected code (decimal for display or binary for further processing).

Digital light meter

Comparison operations in digital measuring devices are performed by special comparison devices. Usually, the final result of the measurement in such devices is obtained after storage and certain processing of the results of separate operations for comparing the analog value X with different discrete values of the sample value N (comparison of known fractions of X with N of the same value can also be do).

The numerical equivalent of X is presented to the measuring device by means of output devices in a form convenient for perception (digital display) and, if necessary, in a form convenient for input into an electronic computer (computer) or into an automatic control system (digital controllers, programmable logic controllers, intelligent relays, frequency converters).In the second case, the devices are most often called digital sensors.

Digital nonometer

In general, digital measuring devices contain analog-to-digital converters, a unit for generating a reference value N or a set of predefined values of N, comparators, logic devices, and output devices.

Automatic digital measuring devices must have a device that controls the operation of their functional units. In addition to the necessary functional blocks, the device may contain additional, for example, converters of continuous values X to intermediate continuous values.

Such converters are used in measuring instruments where the intermediate X can be more easily measured than the original. The conversion of X to electrical quantities is often resorted to when measuring various non-electrical quantities, in turn electrical ones are often represented by equivalent time intervals, and so on.

See also:

Analog to Digital Converters (ADC) are devices that accept input analog signals and, accordingly, their output digital signals, suitable for working with computers and other digital devices, i.e. usually the physical signal is first converted to analog (similar to the original signal) and then the analog signal is converted to digital.

Digital meters use a variety of automatic measurement methods and measurement circuits. A separate n determines the specificity primarily of the comparison methods.

X and N can be compared by balancing and matching methods. In the first method, the change in the values of N is controlled until the equality (with discreteness error) of the values of X in N or the effects produced by them is ensured. According to the second method, all values of N are compared simultaneously with X, and the value of X is determined by the value that matches it (with discreteness error) n.

In the matching method, several comparators are usually used simultaneously, or X has the ability to act on a common device that reads the N value that matches it.

A distinction is made between trace, sweep, and bitwise balancing methods, as well as count trace or read trace matching methods, periodic counting, or periodic counting of comparison results.

Digital multimeter

The first digital measuring instruments in history were spatial coding systems.

In these devices (sensors), in accordance with the measurement scheme, the measured value is converted with the help of an analog converter into a linear movement or an angle of rotation.

In addition, in the analog-to-digital converter, the resulting displacement or rotation angle is encoded using a special code mask, which is applied to special code disks, drums, rulers, plates, cathode-ray tubes, etc.

Masks create symbols (0 or 1) of the number N code in the form of conductive and non-conductive, transparent and opaque, magnetic and non-magnetic regions, etc. From these areas, special readers remove the entered code.

The most common method of removing ambiguity errors is based on the use of special cyclic codes, where adjacent numbers differ in only one bit, i.e. the read error cannot exceed the quantization step. This is achieved due to the fact that when each number is changed by one in the cyclic code, only one character is changed (for example, the Gray code is used).

Digital encoder

Depending on the implementation of the encoder, spatial encoding transducers can be divided into contact, magnetic, inductive, capacitive and photoelectric transducers (see — How encoders work and work).

Examples of digital meters: