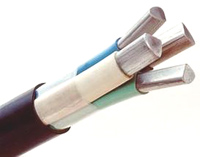

Repair of power cable terminations

Cable terminals

Different types of end seals are used in switchgear to terminate cables at their connection points.

Terminals for power cables with paper and plastic insulation must be performed in accordance with the technical documentation.

Dry seals with polyvinyl chloride tapes, as well as end seals in the form of rubber gloves, cannot be used in wet and damp premises, which include substations for the city network and outdoor transformer substations.

For disconnection of cables with a voltage of 1 — 10 kV, KVE terminals with an epoxy mixture housing are used, they are easy to install and are fireproof.

End seal KVED

Internal KVED epoxy seal with double-layer pipes. The distance between the pipes at the exit of the epoxy sheath for cables with a voltage of 10 kV should be at least 25 mm. In the KVED termination, two-layer pipes are placed on the insulation of the wires, the outer layer of which is made of polyethylene, and the inner layer is made of polyvinyl chloride.

To increase the tightness of the cut roots, they are poured with an epoxy mixture. To avoid penetration of the impregnating composition of the cable insulation, a step is made between the layers of the pipe (the upper polyethylene layer is cut off) at a distance of at least 20 mm, the place is treated with a special PED-B glue that has good adhesion (adhesion ) to the epoxy resin. This glue is used to lubricate the inner surface of the upper end of the tube, which is placed on top, and a bandage of twisted twine is applied to the tube at this point. The assembled seal is painted with a special enamel.

End seal KVEN

The KVEN end seal differs from the KVED in that, instead of double-layer tubing, nitrite rubber tubing is used to seal the core insulation. These pipes provide less moisture protection than double wall pipes and therefore should not be used in damp environments.

End seal KVB

End fittings for internal installation in steel funnels KBB (internal bituminous end fittings) are widely used. Funnels made of steel fittings are available in oval and round shapes. In these end fittings, 3 — 4 layers of insulating tape (adhesive polyvinyl chloride or varnished cloth with adhesive varnish) are wound on the insulation of the cable cores with 50% overlap, and a conical winding is performed at the place of installation of porcelain bushings for their tight fit. To prevent the bitumen mass from leaking, a tar strip is made at the mouth of the funnel. The funnel nut and cable are painted with enamel. At voltages up to 1 kV, end fittings are installed without porcelain bushings and covers.

Repair of cable terminals

When repairing power cable terminals, it is usually carried out during the routine repair of substation equipment. When repairing the terminals of the power cables, check the correspondence of the distances from the phases to the «ground» with the values specified in PUE... At a voltage of 6 kV, this distance must be at least 90 mm, at 10 kV — 120 mm.

The surface of the ends of the power cables is thoroughly cleaned of dust. During an external inspection, the integrity of the lugs, their compliance with the cross-section of the cable cores and the quality of soldering (welding, crimping) are checked. Detected defects are removed.

On 6 and 10 kV steel funnels, wipe and check the porcelain bushings. If they are chipped or cracked, they are replaced. This work is carried out by cable installers, as it is necessary to dismantle the termination.

If the filling mixture is not enough, it is supplemented. If the phase insulation is broken, it must be restored, after which the cable cores and the body of the funnel are covered with enamel paint.

If the filling mixture is not enough, it is supplemented. If the phase insulation is broken, it must be restored, after which the cable cores and the body of the funnel are covered with enamel paint.

Epoxy end seals are checked and if a leak in the impregnating mixture is found, measures are taken to restore the tightness. Its violation usually occurs as a result of non-compliance with the instructions for degreasing the surface and other technological instructions during the installation of the terminals of the power cables.

To eliminate the leakage of the impregnating composition at the point of entry of the cable into the terminal housing, degrease its lower part in a section of 40-50 mm and the same section of the armor (sheath) of the cable with a rag soaked in acetone or aviation gasoline.The section of the armor (shell) is processed with a hacksaw, knife or file to create a rough surface.

A two-layer coil of cotton tape lubricated with epoxy is applied to the degreased area, then a removable repair form of vinyl plastic, polyethylene, etc. is placed. Tin or cardboard molds are pre-lubricated with a thin layer of grease, transformer oil or other substance to avoid adhesion of the epoxy compound, then poured with the same compound from which the terminal body is made.

If tightness is disturbed at the point where the cable cores exit the terminal body, degrease the flat surface of the body and the exiting sections of the phases 30 mm long. A removable repair mold filled with compound is installed, similar to the previous case.

If tightness is disturbed at the point where the cable cores exit the terminal body, degrease the flat surface of the body and the exiting sections of the phases 30 mm long. A removable repair mold filled with compound is installed, similar to the previous case.

In case of leakage along the cable veins, degrease the damaged surface and apply a double-layer winding of cotton tapes lubricated with epoxy compound. Similarly, leakage of the impregnating composition is eliminated in case of leakage where the tube is adjacent to the cylindrical part of the tip. In this case, a dense bandage of twisted twine covered with an epoxy mixture is additionally applied to the coil.