How to determine the location of a short circuit in the windings of AC electrical machines

In the windings of alternating current electric machines, the following short circuits are possible: between the turns of one coil, between coils or groups of coils of the same phase, between coils of different phases.

The main sign by which you can find a short circuit in the windings of an AC motor is short-circuit heating. To do this, you need to feel the winding of the electric motor after switching off. The coil feel should only be done with the coil off!

To detect a fault in the phase rotor of an induction motor, the rotor is decelerated and the stator is connected to the grid. In the event of a short-circuit of a significant part of the rotor winding or if the motor has a large power, braking at rated voltage becomes impossible, as it causes a large current in the stator and tripping of the motor protection. In such cases it is recommended that the test be carried out at reduced voltage.

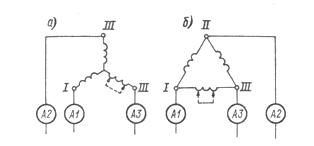

Figure 1.Explanation of signs of short circuit in windings when connected in star a) and delta (b)

In some cases, the shorted part of the motor winding can be immediately identified by its appearance — charred insulation.

It should be borne in mind that in the presence of parallel branches in the winding, a short circuit in one of the phases of the phase (with a significant number of closed turns) can cause heating of the other branch, which does not have a short circuit, since the latter turns out to be closed from the turns of the defective winding branch.

The phase that has a short circuit can be found by the asymmetry of the current consumed by the network. When connecting the winding of an electric motor with a star (Fig. 1, a) in a short-circuited phase, the current (A3) will be greater than in the other two phases. When connecting the winding of an electric motor with a triangle (Fig. 1, b) in two phases of the network to which the defective phase is connected, the currents (A1 and A3) will be higher than in the third phase (A2).

The attempt to determine the defective phase is recommended to be carried out at a reduced voltage (1/3 — 1/4 of the nominal), in the case of an asynchronous motor with a wound rotor, the winding of the latter can be open, and in the case of an asynchronous motor with squirrel-cage rotor or in the case of a synchronous motor, the rotor may spin or be locked. When conducting an experiment with a synchronous motor at rest, its excitation winding should be short-circuited or by discharge resistance.

In the experiment with a stationary synchronous machine, the currents in its phases will differ even if the machine is in good working order, which is explained by the magnetic asymmetry of its rotor. When rotating the rotor, these currents will change, but with a good winding, the limits of their changes will be the same.

A short-circuited phase can also be determined by the value of its resistance to direct current, measured by a bridge or by the ammeter-voltmeter method, the short-circuited phase will have a lower resistance. If it is not possible to separate the phases, three phase resistances are measured.

In the case of connecting the phases of the electric motor with a star (Fig. 1, a), the greatest will be the resistance between the lines, measured at the ends of the phases without short circuits, the other two resistances will be equal to each other and will be more smaller than the first. In the case of a phase connection electric motor with a triangle (Fig. 1, b) the smallest resistance will be at the ends of the phase that has a short circuit, the other two measurements will give large resistance values and both will be the same.

Groups of coils or coils that have a short circuit can be found when the entire coil is supplied with alternating current or only the defective phase by heating or by the value of the voltage drop across their ends. Short-circuited coils or windings will be very hot and have a lower voltage drop (when measuring voltage, it is convenient to use sharp probes that pierce the insulation of the connecting wires). In this case, as above, the defective coils can be found by the DC resistance value.

Short circuits in the winding of the generator can be found by the value of the induced EMF in the phases of the winding, in its groups of windings or in coils. To do this, the generator is put into operation, give it a slight excitation and measure the phase voltages; if the windings are delta connected, the phases must be disconnected. The closed phase will have a lower voltage. To find a coil group or coil that is shorted, measure the voltage across their ends. For high voltage machine, the experiment can be done with residual voltage.

In cases where it is necessary to determine whether there is a defect in the stator or rotor winding, proceed as follows.

The stator winding is turned on at reduced voltage (1/3 — 1/4 of nominal) with the rotor open and the voltage on the rotor rings is measured by slowly rotating the rotor. If the voltages of the rotor rings (in pairs) are not equal to each other and vary depending on the position of the rotor relative to the stator, this indicates a short circuit in the stator winding.

In the case of a short circuit in the rotor winding (with stator failure), the voltage between the rotor rings will be uneven and will not vary depending on the position of the rotor.

The experiment can be done by feeding the rotor and measuring the stator clamp voltage, in which case the opposite picture will be obtained. The voltage supplied to the rotor should be 1/3 — 1/4 of the nominal voltage of the rotor rings, i.e. the voltage of the rings with a stationary rotor and stator switched on at nominal voltage.

After determining which of the windings (rotor or stator) has a turn-to-turn connection, the faulty phase, winding group, or winding is determined by the methods discussed above.

In difficult cases (when a large number of windings are closed) or when for some reason a short circuit cannot be detected, they resort to the method of dividing the winding into parts. To do this, the coil is first split in half and the connection between these parts is checked with a megohmmeter. One of these parts is then split into two parts again and each is checked for connection to the first half and so on until coils are found that have a connection.

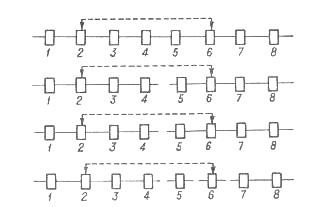

For greater clarity, fig. 2 schematically shows this method of detecting a fault in a phase having eight winding groups when there is a connection between coils 2 and 6 of the winding groups. The division of the coil into parts is shown in sequential order.

The method of sequential division into equal parts allows you to deal with a smaller number of wiring than when dividing the entire coil into groups of coils.

Rice. 2 Finding a short circuit between the coils of one phase

If a short circuit occurs between two phases, then the junction is located similarly to the previous one, dividing the windings into phases. The windings of one of the phases having a connection are divided into two parts, and with a megohmmeter they check the presence of connections of each such half with the second phase . Then the part that is connected to the other phase is again divided into two parts and each of them is checked again, and so on.

The method of series separation of parts is used when finding short circuits in windings with parallel branches.In this case, it is necessary to divide the faulty phases into parallel branches and first determine which branches have a connection, and only then apply this method to them.

Since short circuits between phases or groups of windings are more often found in the front parts of the windings or connecting wires, it is sometimes possible to immediately find the point of connection by lifting and moving the front parts while simultaneously checking with a megohmmeter.