Repair of belt drives

Malfunctions in the belt drive and methods of their elimination

Damage to the belt drive can lead to damage not only to the transmission itself, but also to the electric motor. The main malfunctions of belt drives are as follows.

Damage to the belt drive can lead to damage not only to the transmission itself, but also to the electric motor. The main malfunctions of belt drives are as follows.

Improper belt tension... Too much belt tension will cause the bearings to overheat. This malfunction is eliminated by loosening the belt tension (if the electric motor is mounted on a slider) or by re-sewing. If the tension is too weak, the slippage of the belt increases and its leakage occurs, which increases the energy loss in the transmission. At the same time, the fastening of the entire electric motor and its individual parts is also weakened, the bearings overheat and wear out quickly.

A loose belt should be tightened with a tension roller by moving the machine to a slide or changing.It is not possible to sprinkle rosin on the belt (to increase friction), because the rosin dust, falling into the bearing and mixing with the oil, forms a thick mass that causes rapid wear of the bearings.

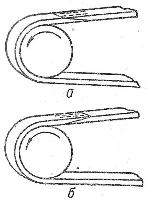

Rice. 1. Sewing the belt: a — correct, b — incorrect

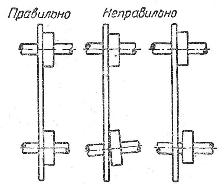

Rice. 2. Checking the correct installation of the rollers

Improper stitching of the belt, as a result of which shocks occur when the seam is applied to the roller (Fig. 1, b). The belt must be sewn as shown in fig. 1, a.

Improper position of the belt on the pulleys... Driven and driven pulleys must be placed exactly opposite each other so that their axes are parallel. If the pulleys are properly installed, the belt will not fall off.

Improper position of the belt on the pulleys... Driven and driven pulleys must be placed exactly opposite each other so that their axes are parallel. If the pulleys are properly installed, the belt will not fall off.

The correctness of the relative position of the rollers is checked with a ruler, which must completely fit the rims of the two rollers (Fig. 2).

Incorrect selection of the diameters of the drive and driven pulleys... With a very small diameter of one of the pulleys, the wrapping angle decreases and the slippage of the belt increases, which worsens the operation of the transmission.

Belt drive pulley sizes are selected based on the following:

a) the ratio of the diameters of the rollers must be no more than 6 to 1,

b) the distance between the axes of the rollers must be in the range of three to ten times the sum of the diameters of the rollers,

c) the speed of the belt should not exceed 20 m / s.

Wrong choice of thickness and width of the belt... This leads to increased friction in the bearings and their rapid wear.