Measures to ensure the reliability of the operation of electrical devices

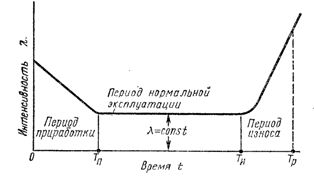

When considering the characteristics of any electrical device, three periods of its operation are distinguished: leakage, normal operation and wear.

When considering the characteristics of any electrical device, three periods of its operation are distinguished: leakage, normal operation and wear.

The expiration period of an electrical device related to the initial stage of operation of the device after its manufacture and installation. During this period, breakdowns often occur due to short-term overloading of parts, technological, manufacturing and assembly defects. The expiration period for most electrical devices is several tens of hours.

In order to reduce reliability failures during the expiration period, they usually strive to ensure that during the assembly of an electrical device in the factory, its installation, and also after major repairs, defective elements are not used in it. To do this, all finishing elements pass a preliminary test before assembly - a test for a certain time in conditions close to working conditions.For example, in direct current electric machines, before their release from the manufacturer, the grinding and loading of the brushes of the collector or slip rings and the adjustment of the bearing units are carried out.

Rice. 1. Curve of the degree of failure during operation of an electrical device

What is important is the TP drain time during which reliability corresponding to its normal operation is achieved. Failures during the run-out time from 0 to T = Tn additionally do not affect the reliability of the device during its operation in the period from Tp to Ti, where Ti is the wear time.

The period of normal operation of an electrical device comes after the end of the expiration period, and unlike the latter, it can be very long and amount to thousands and tens of thousands of hours. During normal operation, devices usually experience sudden failures.

During the period of normal operation, the lowest, approximately constant level of intensity of sudden failures is observed, and accordingly, the reliability of the device remains approximately the same throughout the period. The duration of the period of normal operation is limited by the wear of its elements.

A period of wear and tear of an electrical device occurs after the end of the period of normal operation. Malfunctions due to wear and tear begin to be added to sudden failures of electrical device elements, and the overall degree of failure increases. Time Tp can be called the average value of the service life of an electrical device, taking into account wear or its technical resource, provided that there is no repair.However, when the device is repaired by replacing worn parts, its service life can be significantly increased.

The operating time of the device with a constant frequency of failure in operation is always less than the durability or technical resource. At the same time, the average time of trouble-free operation of the device (or the average time to the first failure) Tav = 1 /λ is usually much longer than the longevity or technical resource. For example, if during the period of normal operation the intensity of sudden failures in the operation of the device is not high, then the time value Tav can be very large and can be measured in tens or hundreds of thousands of hours. This time shows how reliable the device is under normal use.

To characterize the reliability of an electrical device, the main thing is the period of normal operation, which is associated with long-term operation under certain climatic and other conditions. This period corresponds to the operation of electrical devices, both single and reusable, while the wear period applies only to refurbished reusable devices.

Repair of electrical appliances is carried out in order to reuse worn or damaged equipment and thus increase its service life. The number of electrical devices repaired often exceeds the number of new devices manufactured. That is why it is very important to properly organize the repair of electrical devices and achieve its high quality.Malfunctions and damage to electrical devices and their elements can be different: sudden damage, for example, cracks as a result of mechanical impact or heating, short circuit in the windings, destruction of the insulation or gradual damage, such as corrosion, wear, aging of the insulation.

The nature of the repair of electrical devices is determined by the type of damage. Sudden failures are eliminated in the course of the so-called emergency repair, which cannot be planned in advance. Gradual damage to device elements cannot be completely repaired. You can only extend the time during which they appear, for example, reduce the rate of wear or aging. Partial removal and prevention of gradual failures is the content planned repair of electrical appliances.

A special system for scheduled preventive repair and maintenance of electrical devices... It provides for the following types of work:

— Maintenance (daily inspection of devices, their lubrication, cleaning from dust, dirt and removal of minor damages); technical inspections (determining the condition of the devices and identifying the volume of preparatory work to be carried out during the next repair, cleaning the equipment and removing minor damage without disassembling);

— Maintenance — a minimum volume in terms of volume, ensuring the possibility of extending the operation of the device until the next major repair (cleaning of electrical equipment from dust and dirt, removal of minor damage and damage, washing of electric motor bearings and changing the oil in them , checking and troubleshooting the control device, changing the brushes; during current repairs, the equipment of the devices is disassembled);

— overhaul (work on the replacement or restoration of the main and, as a rule, the most complex elements of the devices: rewinding the windings of the stator of the electric motor, replacing the terminals of the high-voltage switch, eliminating damage to the switching device of a power transformer and etc., during major repairs they perform partial or complete disassembly of the repaired devices).

Rice. 2. Overhaul of the electric motor

Current repairs are carried out several times more often than the main ones. The periods between inspections and repairs of electrical devices are established in accordance with the manufacturers' instructions, the current rules for the technical operation of electrical installations.

Establishing the frequency of inspections and repairs allows you to plan and organize them in the most correct way, as well as to connect their implementation with the work of the enterprise, the workload of the repair personnel and the availability of the necessary materials and equipment. In order not to disturb the normal activities of the enterprise due to downtime of the equipment, the work on current and major repairs is carried out in strictly defined and predetermined terms.

In some cases, a major repair of an electrical device can be carried out, regardless of the arrival of the term set for it. For example, an overhaul may be carried out on a power transformer, where there is a sharp decrease in insulation resistance, damaged windings, terminals, etc., or an electrical device that has damages that prevent its further normal operation or pose a threat to the safety of service personnel can be found.

The correct execution of documentation contributes to the improvement of the organization of repair work, in addition, it allows you to get the necessary insight into the condition of the equipment of electrical devices and, on this basis, correctly determine the time and volume of subsequent repairs. Defect lists give a complete picture of the state of the equipment of electrical devices and therefore allow you to determine in advance and accurately the scope and nature of the work that needs to be done. The record of current repairs is made in a logbook or on forms. Special acts for the acceptance and delivery of repair works formalize the performance of major repairs.