How to make a thermocouple

A thermocouple is a thermometer whose operation is based on the ability of two different metal conductors or semiconductors connected to each other to generate an emf proportional to the temperature of the junction, or, as they say, the junction. Thermocouples are connected to a millivoltmeter or potentiometer, according to the readings of which the temperature of the heated node is determined.

A thermocouple is a thermometer whose operation is based on the ability of two different metal conductors or semiconductors connected to each other to generate an emf proportional to the temperature of the junction, or, as they say, the junction. Thermocouples are connected to a millivoltmeter or potentiometer, according to the readings of which the temperature of the heated node is determined.

Read more about the device and the principle of operation of thermocouples here: Thermoelectric converters

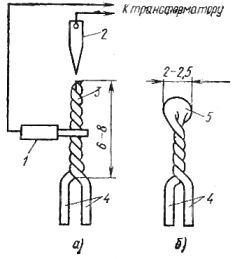

The thermocouple is easy to make yourself (Fig. 1, a, b). To do this, two wires 4 (for example, from chromel and copel alloys) are twisted together to a length of 6-8 mm and after careful stripping, they are soldered with pure tin or welded. Only acid-free fluids are used for soldering. After welding, the head 5 of the thermocouple can be forged with light blows with a hammer to obtain the shape of a spade.

Thermocouples with such a head are used to measure the temperature of the cores of machines and transformers.To install the thermocouple, the core sheets are moved apart and the spade-shaped head of the thermocouple is inserted into the gap formed.

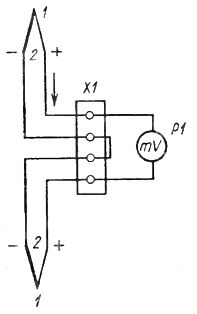

Often several thermocouples are built into an electrical product to measure the temperature of its various parts. In this case, the ends of the thermocouples are connected in series to the same device. The design of the switch must ensure that there is no contact between the thermocouples when switching from one thermocouple to another, otherwise the needle of the device will receive sharp shocks.

For all thermocouples to have the same resistance, they must be made of the same end length and of the same wire.

In addition, after production, the thermocouples must be checked with each other, for which they are immersed in a closed container with transformer oil heated to a temperature of 70 — 80 ° C, and by moving the switch knob from one thermocouple to another, it is detected thermocouple with maximum readings. This thermocouple is taken as a control and the readings of the other thermocouples are compared with its readings while shortening their lengths to equalize the resistances.

Rice. 1. Production of a thermocouple (a) and its appearance after welding (b): 1 — tongs, 2 — welding electrode, 3, 4 — wire, 5 — head

Rice. 2. Reverse serial connection of thermocouples: 1 — hot junction, 2 — cold junction

When making measurements with this method, remember that the current flowing through the thermocouple depends on the temperature difference between the monitored point and the end of the thermocouple to which the measuring device is connected.Therefore, to find the temperature of the controlled point, it is necessary to know the temperature at the location of the measuring device.

This property of the thermocouple makes it possible, if necessary, to measure the temperature difference at two controlled points for which two thermocouples are connected in an anti-series manner.