How to properly charge the battery

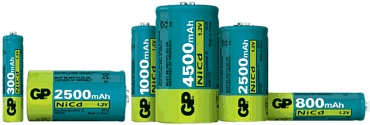

In the modern market for chemical sources of reusable direct current, the most common are batteries of the following six types:

In the modern market for chemical sources of reusable direct current, the most common are batteries of the following six types:

-

Lead-acid batteries;

-

Nickel-cadmium batteries;

-

Nickel-metal hydride batteries;

-

Nickel-zinc batteries;

-

Lithium-ion batteries;

-

Lithium polymer batteries;

Many people often have a very reasonable question, how to properly charge this or that battery so as not to spoil it ahead of time, extend its service life as much as possible and at the same time get high quality of our work? This article will help you get an answer to this question in relation to different types of batteries from the most common today.

The safest, traditional method of charging lead-acid batteries is DC charging, when its value in amperes does not exceed 10% (0.1C) of the battery capacity value in ampere-hours.

Despite this tradition, some manufacturers themselves indicate the exact value of the maximum allowable charging current for a particular battery, and this figure in amperes often reaches 20-30% (0.2C-0.3C) of the battery capacity for ampere-hours.So if the battery has a capacity of 55 amp-hours, then an initial charge current of 5.5 amps is the safest solution.

It should be remembered that the voltage of one cell of a lead-acid battery should not exceed 2.3 volts, therefore, when charging with direct current, you should monitor the voltage, for example, a 12-volt battery consists of 6 battery cells, which means that the total voltage at the end of the battery charging process should not exceed 13.8 volts.

For example, if a lead-acid battery with a capacity of 100 ampere-hours was charged with a constant current of 20 amperes, then after 6-7 hours of such charging 90% of its capacity will already be charged, then the constant should be set to voltage and after 17 hours charging will be fully completed.

Why so long? As the current will drop and the voltage will slowly, exponentially approach the target value of 13.8 volts. A battery charged in this way is reliable for both buffer and cycle operation.

There is another way to charge lead-acid batteries that is suitable for cyclic operation. This method allows you to charge the battery for 6 hours.

The charging current is set to 20% of the battery capacity in amp-hours, and the voltage is set to 14.5 volts (for a battery with a nominal voltage of 12 volts), and so the battery is charged for 5-6 hours, then the charger turn off...

To be honest, it should be noted that modern high-quality specialized chargers simply do not allow critical situations during the charging process.

Nickel cadmium batteries should be charged with caution, fearing overcharging at the very end, because in the process of charging the positive oxide-nickel electrode, the evolution of oxygen gradually increases, and the rate of current utilization gradually decreases. So the process of charging a nickel-cadmium battery is accompanied by an increase in its internal pressure.

It is best to charge nickel-cadmium batteries at temperatures from +10 to +30 degrees, since oxygen is absorbed by the negative cadmium electrode at an optimal rate.

For cylindrical roller batteries, high-speed charging is permissible because the electrodes are tightly assembled there, but their charging efficiency in the range of charging currents from 0.1C to 1C is almost unchanged. In the standard charging mode for nickel-cadmium batteries, in 16 hours the cell is fully charged from 1 volt to 1.35 volts at a current of 0.1 C, and in some cases 14 hours are enough.

To accelerate the charging of some modern nickel-cadmium batteries, an increased direct current can be applied, but in this case a special control system is required that does not allow recharging.

In general, nickel-cadmium batteries can be safely charged with a constant current of 0.2C-0.3C for a period of 6 to 3 hours, it is only important to monitor the charging time. Here we even allow recharging up to 120-140%, then the discharge capacity will be close to the battery rating.

For nickel-cadmium batteries, the memory effect is inherent, therefore, only a fully discharged battery should be charged, otherwise, due to the resulting under-discharge, an additional double electric layer, the battery will not be able to fully discharge the charge completely. Store nickel-cadmium batteries in a fully discharged state. For charging nickel-cadmium batteries, as well as for other types, special chargers are produced.

Nickel-metal hydride batteries were developed to replace nickel-cadmium batteries. With the same dimensions, they have 20% more capacity and are free of the memory effect, so they can be charged in any state. However, if the NiMH battery has been stored partially discharged for more than 30 days, it must be fully discharged before use and then fully charged again.

It is necessary to store nickel-metal hydride batteries in a partially charged state, approximately 40% of its nominal capacity. Before charging new batteries for use, it is useful to train them by fully discharging them and charging them 4-5 times, then the working capacity of the batteries will be greater than without such training.

Charging conditions are similar to nickel-cadmium - at a current of 0.1C, charging will last from 15 to 16 hours in time, these recommendations are standard for all manufacturers of nickel-metal hydride batteries; like nickel-cadmium batteries, nickel-metal hydride batteries are sensitive to overheating and should not be allowed to heat above 50 degrees.

Batteries of this type are charged with direct current at a voltage of 1.4 to 1.6 volts per battery cell, and a battery with a voltage of 0.9 volts is considered fully discharged, further discharge will be harmful to the battery.

When a nickel-metal hydride battery is almost fully charged, it starts to heat up more because the source energy is no longer going to support the chemical reaction of the charge, and if the charging current is high enough, the temperature of the battery starts to rise sharply after the boot process is complete. So, by installing a temperature sensor, you can monitor the charging status while the maximum allowable temperature is no more than +60 degrees. Special chargers are available for charging nickel-metal hydride batteries.

A nickel-zinc battery has a nominal voltage of 1.6 volts, that is, for charging you need to apply 1.9 volts to it, with a current of 0.25C. It can be fully charged in 12 hours with a special charger and from any country. It has no memory effect, but to extend the service life, increase the number of working cycles of a nickel-zinc battery, it only needs to be charged to 90% of its capacity.

Otherwise, it is similar to a nickel-metal hydride battery, but the discharge voltage here is 1.2 volts, and the number of duty cycles is three times less. The maximum permissible temperature is +40 degrees.

Lithium-ion batteries are usually charged first at a constant current of 0.2C to 1C at a voltage of 4 to 4.2 volts for 40 minutes, and then at a constant voltage of 4.2 volts per cell. If charging is done with a current of 1C, the time to fully charge the lithium-ion battery will be only 2-3 hours.

If the charging voltage exceeds 4.2 volts, the life of the Li-ion battery will be reduced. Additionally, lithium-ion batteries are highly discouraged from being recharged. this leads to the fact that lithium metal is deposited on the negative electrode and oxygen is actively released on the anode, as a result of which thermal leakage can occur, an increase in pressure inside the battery case, and this can lead to a decrease in pressure.

Thus, it is safe and proper to charge the Li-ion battery in such a way that the voltage does not exceed the value recommended by the battery manufacturer.

Some lithium-ion batteries contain protection circuits that protect the lithium-ion cell from overcharging, the protection is triggered when the battery temperature reaches +90 degrees. Some batteries have a built-in mechanical switch that responds to overpressure in the battery case.

Often, a monitoring system built into a lithium-ion battery monitors the value of the input charging voltage, and when the value falls within the allowable range, the charging process begins; if the limit voltage is exceeded or below the lower allowable value, charging will simply not start.

However, you should be careful with the process of charging lithium-ion batteries, monitor the voltage and current. Basically, any device using a lithium-ion battery often has a built-in charger or comes with an external charger.

Lithium-polymer batteries do not differ in the way of charging from lithium-ion batteries.The only difference is that a lithium-polymer battery contains a gel-like electrolyte, not a liquid, and even when overcharged or overheated, it doesn't explode like its lithium-ion counterpart does, it just swells. This explains the trend of displacement from the market of lithium-ion batteries lithium-polymer.

Also read on this topic: How do batteries work and work?