How to measure temperature with a thermoelectric thermometer

When measuring the temperature of an air stream or a liquid stream with a thermoelectric thermometer (a temperature measuring device whose receiving part is a thermocouple), its sensitive element (connection point) is set perpendicular to the stream or at an angle to it (to the stream) .

The working junction of the thermocouple should preferably be located on the axis of flow. If the thermocouple is installed in a chamber with process equipment or an air duct, the protruding part must be at least 20 mm. If the thermocouple is installed horizontally, its protruding part must be kept longer than 500 mm.

Before installing the thermocouple, nozzles or recesses are welded to the walls of the processing equipment, which are used to install thermometers.

The free ends of the thermocouple with the help of connecting wires are connected to the measuring device through the terminal block.The sum of the resistance of the connecting wires and the thermocouple must be less than the value indicated on the scale of the millivoltmeter.

The free ends of the thermocouple with the help of connecting wires are connected to the measuring device through the terminal block.The sum of the resistance of the connecting wires and the thermocouple must be less than the value indicated on the scale of the millivoltmeter.

If this condition is not met, then an additional resistor (coil) is used to adjust the resistance.

One of the features of working with thermoelectric thermometers is that in order to reduce the measurement error, it is necessary to ensure the constancy of the temperature at the free ends.

Since the temperature in the area where the head is located can fluctuate, then with the help of special compensation wires, which are close in characteristics to thermocouple thermocouples, these free ends tend to move away from the object, in the constant temperature zone to the secondary device. However, with a significant length of connecting line, this is not always possible.

In this case, the compensation wires are brought to a constant temperature zone and then copper connecting wires are laid.

Compensating wires are produced with a length of 20 to 50 m of types PVK, PKVG, PKVP (Tair = 40 — 60 ° C), PCL, GKLE (Tair <80 ° С dry rooms), KPZh (Tair> 100 ° C) and etc. In addition, wires with increased flexibility PKVG and PKVP can be used on mobile objects.

Compensating wires are produced with a length of 20 to 50 m of types PVK, PKVG, PKVP (Tair = 40 — 60 ° C), PCL, GKLE (Tair <80 ° С dry rooms), KPZh (Tair> 100 ° C) and etc. In addition, wires with increased flexibility PKVG and PKVP can be used on mobile objects.

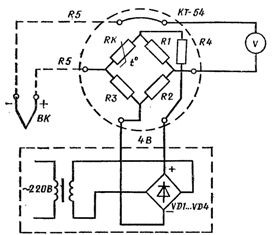

For automatic temperature compensation, KT-54 type boxes are used in the circuits, which are an unbalanced bridge powered by a direct current source.

When the ambient temperature deviates from 20 ° C, the balance of the bridge is disturbed.The value of the potential difference across the diagonal of the bridge is always equal to the change in the emf of the thermocouple, but with the opposite sign; thus compensating for temperature measurement error.

When using the KT-54 box, before measuring with the device turned off, use the corrector to set the pointer to zero. When connecting measuring devices, observe the polarity. The polarity of the thermoelectrodes is indicated on the thermocouple.

Rice. 1. Scheme of a thermoelectric thermometer with a compensation box, type KT-54

For calibrating thermoelectric thermometers, compensation boxes are equipped with replaceable additional resistors, the parameters of which are indicated in the technical sheet of the box.

During long-term operation of thermoelectric thermometers, it is necessary to periodically check them according to graphs and special calibration tables.

Thermoelectric thermometers are convenient for measuring high temperatures and in hard-to-reach places.

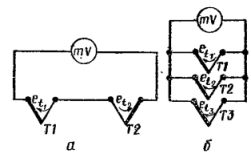

It is convenient to use thermocouples when it is necessary to know the temperature difference between some two points, in one of which one thermocouple is placed and in the other - the second thermocouple. In this case, the thermocouples are turned on oppositely, and then the measuring device measures the difference in thermo-EMF et1 — et1 = de, which is proportional to the temperature difference. The scale of such a measuring device can be calibrated directly in degrees.

Rice. 2. Schemes for switching on thermoelectric converters (thermocouples): a — when measuring the temperature difference between two points, b — when measuring the average temperature of several points.

It is recommended to use thermocouples when measuring the average temperature of several points. In this case, the connection points of the thermocouples are placed at the measurement points, the thermocouples are connected in parallel with each other (Fig. 2, b). The measuring device in this case shows the average value of thermo-EMF, which in turn is proportional to the average temperature of several points.