Combating wood decay from overhead lines

In operation, especially in rural areas, there are a large number of lines with wooden supports and with wooden attachments subject to decay. In order to increase the reliability of the lines and reduce operating costs, it is necessary to carefully monitor the condition of the wood and take preventive measures to protect the wood from rotting — it is necessary to create the most unfavorable operating humidity conditions for rotting mushrooms (absolute humidity in the above-ground part is below 20% and in the underground part — above 70%).

In operation, especially in rural areas, there are a large number of lines with wooden supports and with wooden attachments subject to decay. In order to increase the reliability of the lines and reduce operating costs, it is necessary to carefully monitor the condition of the wood and take preventive measures to protect the wood from rotting — it is necessary to create the most unfavorable operating humidity conditions for rotting mushrooms (absolute humidity in the above-ground part is below 20% and in the underground part — above 70%).

To ensure that the support is dry, it is necessary, if possible, to protect it from rain, snow and groundwater. During construction and repair, it is necessary to pay special attention to the quality of the lining of the supports and to limit cuttings and fittings as much as possible. The place of articulation with the attachment is not processed. Holes for hooks, pins and bolts are drilled strictly according to their diameter. The heads of the supports are cut at an angle so that moisture is not trapped, and they are protected with plastic or slate.

To ensure that the support is dry, it is necessary, if possible, to protect it from rain, snow and groundwater. During construction and repair, it is necessary to pay special attention to the quality of the lining of the supports and to limit cuttings and fittings as much as possible. The place of articulation with the attachment is not processed. Holes for hooks, pins and bolts are drilled strictly according to their diameter. The heads of the supports are cut at an angle so that moisture is not trapped, and they are protected with plastic or slate.

When installing supports in the ground without a reinforced concrete attachment, the exit point from the ground is protected with antiseptic bandages. The foot of the support and the pit of the foundation must be thoroughly cleaned of the top layer of vegetation, roots and other organic materials.

Periodic inspection of the degree of decay of parts of wooden supports is carried out once every three years. The degree of decay is determined by external inspection (local external foci of decay, tapping (a clear ringing sound indicates healthy wood, a dull sound indicates decay of the core), as well as piercing wood in dangerous places with a probe in the form of a flat blunt awl with half a centimeter divisions.

The probe is inserted into the wood only by pressing the hand, without using a hammer. The thin outer wall must be pierced to reveal the actual depth of the internal decay. When checking wooden attachments, the wood hidden in the ground should be torn off at a depth of 0.3-0.5 m.

The vertical part of the supports is drilled in three points of the circle at an angle of 120 °. Horizontal parts (crossbars) are measured at two points: above (maximum decay) and below the log. The depth of decay was determined as the mean value of the measurements. The results of the measurements are recorded in the defect declaration, indicating the maintenance number.

The prop or attachment is considered unfit for further operation and must be replaced if the depth of its decay along the radius of the log is more than 3 cm with a log diameter of 25 cm or more, or is 20% of the diameter of a log thin logs.

On existing lines with wooden attachments, the decay of which was found during the inspection, it is necessary to replace them with reinforced concrete ones.The same attachments should be installed on lines with single-post supports when wood decay is found where the support emerges from the ground.

In the absence of reinforced concrete attachments, wooden attachments impregnated with an antiseptic or protected with antiseptic bandages may be permitted as an exception.

Antiseptic treatment of wooden supports

The best way to protect wood from rotting is factory impregnation of logs with a mixture of creosote and fuel oil in special pressure chambers. Wood impregnated in this way serves 20 years or more.

The best way to protect wood from rotting is factory impregnation of logs with a mixture of creosote and fuel oil in special pressure chambers. Wood impregnated in this way serves 20 years or more.

In the absence of impregnated wood at the plant, it is necessary to self-antisepticize the wood, which increases its service life by 3-4 times compared to untreated wood.

Diffusion method

The diffusion method of impregnation consists in applying a special paste to the surface of raw wood with a brush, which gradually, along with moisture, penetrates into the pores of the wood and preserves it, killing fungi that cause rot. The antiseptic method of raw wood gives the best results.

Dry wood with a moisture content of less than 20% is not treated diffusely.

If the wood is collected for the future, it is treated with a paste and placed in dense piles for 3 months, after which the antiseptic process is considered complete. The bowls are covered so that moisture does not evaporate from the wood.

If the wood will be used soon, it is covered with paste and stacked for 2-3 days until the paste hardens, after which a waterproofing layer is applied to the paste (petroleum bitumen heated to 180 ° C, coal varnish or bitumen emulsion, consisting of 53% petroleum bitumen, 1.35% wood tar, 0.25% sodium hydroxide and 45.4% water).Charcoal varnish is applied cold and hardens after 12-24 hours. The bitumen emulsion is also applied cold and hardens for 2-3 hours.

Wood material covered with waterproofing is immediately sprinkled with sand to increase its strength.

The parts of the supports buried in the ground impregnated in this way are wrapped with a layer of roofing tar paper or roofing felt to protect the waterproofing layer.

The wood of the working supports should be processed in places where rotting has begun.

As a preventive measure, the most critical supports are antiseptic: at railway crossings, communication lines, as well as installed in places with high humidity.

Antiseptic treatment of partners, curtains, holes

The parts affected by external decay are cleaned of decay and covered with a layer of paste with the help of a brush (recipes #1, 2, 3 and 4). All horizontal slots and connecting parts are filled with paste. After the paste dries, a waterproofing layer is applied to the treated surface — heated bitumen with sand or Kuzbasslak. The ends of racks, attachments and traverses are protected in the same way.

Antiseptic bandages

To protect the support areas in places especially susceptible to rotting (the outer part of the attachments near the surface of the ground), they are wrapped with antiseptic bandages. Moisture from the soil gradually penetrates the wood and rises to the top of the pole. Passing the dressing, she dissolves the antiseptic and irrigates the nearest part of the support with it.

A layer of special paste containing sodium fluoride is applied to a strip of roofing felt, roofing felt, parchment or burlap 50 cm wide.

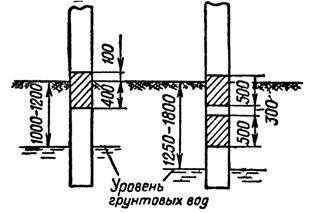

The degree of attachment damage by rotting depends on the groundwater level: the lower the groundwater level, the deeper the wood is affected.

Antiseptic dressings protect the wood under the dressing and the area 20-30 mm above and below the dressing.

One bandage is placed at a depth of 1–1.2 m at the groundwater level; two strips are placed at a depth of 1.2–2 m (Fig. 1).

Attachments made of untreated wood at the correct level are covered with paste and wrapped with a layer of roofing tar, brisol or parchment to prevent leaching of the antiseptic into the ground.

For a tight fit of the bandages, they are nailed with roofing nails and covered with wire. The surface of the waterproofing bandage is covered with bitumen.

Working devices, when signs of rotting in the "ground-air" zone are detected, are torn off at a depth of 30-40 cm, thoroughly cleaned of dirt and rot, then covered with a layer of paste 3-4 mm thick and tightly wrapped with an overlapping strip of roofing material or pergalin with a width of 15 cm. The bandage is fixed with nails and wire, after which the pit is covered with earth and rammed.

One bandage consumes 0.6-1.0 kg of paste and 0.4-0.5 kg of bitumen. The use of antiseptic dressings increases the service life of the attachment by 5-6 years.

Rice. 1. Placement of antiseptic dressings at different levels of groundwater

When passing the line through the pasture, in order to protect the animals from poisoning, it is necessary to sprinkle the outer part with earth or cover it with a layer of tar and bitumen. Do not spread or leave the paste in the workplace.

The recipe for pastes to combat wood decay from overhead lines

Mosenergo recipe No. 1: sodium fluoride — 36%; dinitrophenol — 10%; sodium or potassium dichromate — 12%; soda ash — 2%; sulphide liquid extract — 7%; water — 33%.

Mosenergo recipe No. 1: sodium fluoride — 36%; dinitrophenol — 10%; sodium or potassium dichromate — 12%; soda ash — 2%; sulphide liquid extract — 7%; water — 33%.

The sulfide extract of lye is dissolved in hot water, after which antiseptic and other components are added. In order to obtain a thicker, non-slippery paste, a little fat clay is added to the resulting composition.

Recipe number 2: uralite or triolite — 49%; bitumen — 17%; green oil — 24%; water — 10%.

Recipe number 3: sodium fluoride -40%; Kuzbasslak — 50%; water — 10%.

Recipe number 4: dinitrophenol — 50%; Kuzbaslak — 40%, water — 10%.

Recipe No. 5 TSNIIMOD — paste FHM -7751P: preparation FHM -7751 — 80%; kaolin — 15%; extract of sulfide liquid — 4.5%; moisturizing agent OP-7 — 0.5%.

To prepare pastes No. 1, 2, 3, 4, the antiseptic is ground, sifted through a sieve with holes with a diameter of 1-2 mm and mixed with water in a wooden or iron container.

The bitumen together with green oil (a flammable substance) should be carefully heated in a hood over low heat to 70 ° and, after complete dissolution, poured into a tank with an antiseptic and mixed well. If Kuzbasslak is used, it is heated to 40-50 ° and then mixed with an antiseptic.

Attention: antiseptics are poisonous and infect the mucous membrane and skin, and with prolonged exposure they destroy teeth and bones, causing poisoning. Kuzbaslak, bitumen and green oil affect the skin and eyes. When making pastes, you need to be careful, work in tight coveralls, gloves and glasses.

After working with antiseptics, especially before eating, wash your hands well with soap and wash the places where the antiseptic entered. Coveralls should be removed and stored in a warehouse with antiseptics.