Maintenance of solar photovoltaic systems

A solar power plant is inherently an expensive system. And like any equipment, such systems need timely and high-quality service. Although at first glance it may seem so solar power plant it is not as complex a piece of equipment as other power generation installations, but its timely maintenance can increase productivity and significantly reduce potential repair costs.

The fact is that every element of the solar photovoltaic system must function reliably and this must be periodically monitored and, if necessary, defective parts must be repaired immediately. As a result, the solar power plant will generally work as efficiently as possible and last for a long time.

Just think, lightning strikes, birds, rodents, simple overvoltage — various environmental factors that are not noticeable at first glance can lead to a fire that is destructive to the station.

Even just micro-cracks on individual solar modules or damage to thin wires and even just loose terminals can damage the inverter equipment and the electricity generation process will be disrupted.

One way or another, from any such damage, the efficiency of the solar power plant is generally reduced. Therefore, at least regular service checks are required.

Of course, there are also such malfunctions in solar power plants, the roots of which are already laid at the stage of its delivery and installation. These are the so-called warranty cases where defects could have occurred during production or during the transportation of the panels.

Of course, there are also such malfunctions in solar power plants, the roots of which are already laid at the stage of its delivery and installation. These are the so-called warranty cases where defects could have occurred during production or during the transportation of the panels.

Multiple defective silicon cells in one panel will greatly affect the overall performance of a solar power plant, so such defective cells should be replaced as soon as possible. And since the supplier of the station initially gives a guarantee for materials and equipment, it is within his power to immediately replace the defect.

Timely inspection and monitoring of the parameters of all installed solar power plant equipment will help identify factory defects and manufacturing defects.

Another aspect of durability is the initially high-quality approach to building the station. That is: the cross-section of the wires must be selected correctly, the connectors must be of high quality, the grounding must be arranged correctly, etc.

In practice, at the design and construction stage, many factors must be taken into account that can uniquely affect the operation of a solar power plant: the degree of shading of the area, the geographical location, the angle of installation of the panels and especially the temperature characteristics.

For example, the higher the temperature of the solar module, the lower its performance. This means that such a module located on the roof of a building needs additional air circulation during summer days, which can be achieved immediately by leaving a gap between the roof and the modules. The less it overheats, the slower it will break down silicon modules.

In general, timely and professional service is a factor in reducing potential risks, maintaining returns and ensuring high technical and economic performance of the solar power plant throughout its operational life.

As soon as the station is put into operation, it is necessary to systematically monitor its condition in order to notice and eliminate problems as soon as possible.

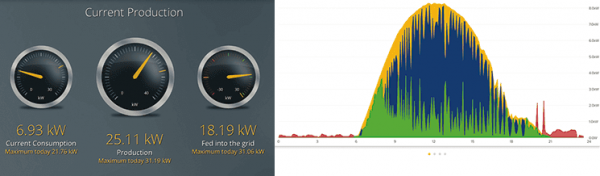

Today, remote software online monitoring allows you to measure many indicators: voltage, current, power, the amount of electricity produced and consumed, the state of connections, the working or emergency state of individual elements, the efficiency of converters, the battery charge level and many other system parameters .

The set of data obtained through remote online monitoring allows you to establish the fact that the solar power plant is stable or that it needs some kind of service.In case of detection of irregularities in the operation of the station, it is possible to remotely change some of the settings that allow changing the power distribution, as well as to upgrade the software of the station itself.

The operational maintenance of the solar plant, based on regular checks by the mobile team, allows on-site diagnostics and, if necessary, repair and restoration works.

The experts will check the equipment and cables for mechanical damage, measure the temperature of the connections of the power circuits, photovoltaic modules, inverters, check the insulation resistance and reliability of the contact and bolted connections, measure the resistance of the grounding of the station, clean the equipment from dirt and dust. After completion, the relevant acts will be drawn up.

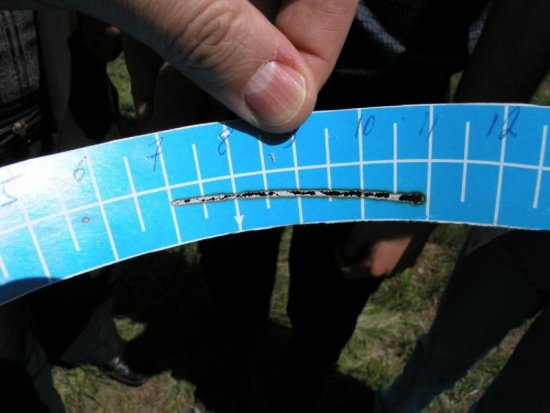

Only visual inspection will now allow you to effectively identify defective PV modules. In addition, the service department will identify the so-called hot spots, burn marks, places of delamination, bubbles, yellowed spots, damage to the junction boxes, etc.

During the service, special attention is paid to the integrity of the fences, the condition of the vegetation in and around the station, the sewage, etc. It is important to regularly clean the surfaces of the solar modules, so that the energy performance of the facility always remains at a high level, otherwise only solar dust can reduce its efficiency by a quarter.

Servicing of solar photovoltaic systems should only be entrusted to professionals.It is ideal if the system provider immediately provides a package of warranty services: IT and visual monitoring, analytics, identification and elimination of causes, and reporting. The service department must have a stock of all necessary spare parts.

The most reliable companies take full responsibility for the monitoring and maintenance of their photovoltaic systems. They often provide their customers with 24/7 support through the operations center. As a result, the operating and maintenance costs of solar PV systems are negligible compared to other types of power plants.