What is partial, complex and full automation

Technological progress is characterized by a continuous expansion of production automation — from partial automation, that is, automatic execution of individual productions, operations, to complex automation, from complex — to full automation with an ever-increasing transition to workshops and automatic factories, providing the highest technical and economic efficiency. …

Partial automation

A prerequisite for production automation is the mechanization of all basic and auxiliary operations of the technological process. Partial automation is a distinctive feature of any production.

The transfer of human functions to the tool-moving machine removed the limitations imposed by human physical capabilities on the development of production and caused a sharp jump in its level and scale, known as the industrial revolution of the late 18th and early 19th centuries.

Since the creation of the first automatic machines, production automation has developed continuously and qualitatively.Replacing bulky steam engine with easy to operate and small in size electric motors fundamentally changed the principles of operation and design of working machines and changed the principles of management.

The individual drive of separate working bodies of the machines and the introduction of electrical connections between them greatly simplified the kinematics of the machines, made them less cumbersome and more reliable.

Compared to mechanical connections, more flexible and convenient in operation, electrical connections made it possible to create a combined electrical and mechanical programmed control, which ensured the automatic execution of immeasurably more complex operations than automatic machines with a mechanical programming device (Advantages of electrical automation systems).

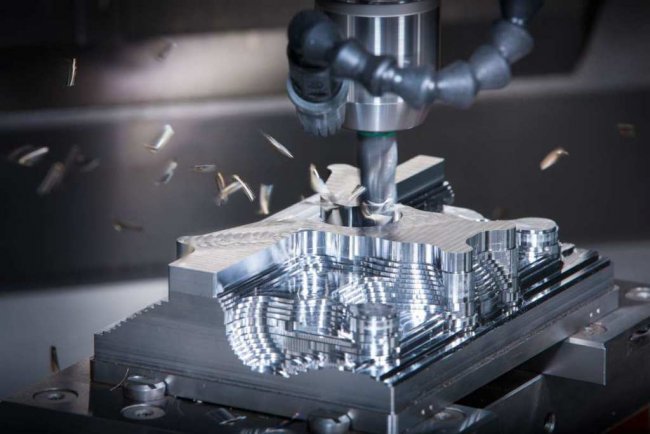

With the electrical connections, not only the necessary sequence of movement of the working organs is easily achieved, but this sequence is easily changed to restore the working machine to process a new product. For example, a modern computer-controlled automatic machine (cf. CNC machine) can handle parts of any shape. To restore such a machine, it is only necessary to change the program.

Electric programmed control can not only perform the necessary cycle of movement of working bodies without human intervention, but also ensure the automatic start of such a cycle when certain conditions are met, for example, when the machine is released from an already processed product, there is a new portion of material and its proper spaces, located in relation to the working organs...

To automatically perform such an operation, the machine must be equipped with sensitive elements — sensors that monitor the fulfillment of individual conditions. In addition, the control system itself must be able to check the set of fulfillment of these conditions, that is, to solve some logical problem (see:A logical operation).

Automatic regulators have become widespread, which, performing their functions much faster and more accurately than a person can, have provided a significant improvement in the technical and economic indicators of many industries and processes. They serve to maintain a constant voltage of the generator, revolutions of the engine, steam pressure and temperature in boilers, strip thickness in rolling mills, temperature in electric furnaces, etc.

There is no production where automatic controllers - devices for controlling automatic control systems - are not used. In some cases, these systems made it possible to create new processes and units that could not be implemented manually (eg nuclear power plants).

Complex automation

The greatest effect of the use of automatic control systems is achieved with comprehensive coverage of the automation of all machines and technological units of a workshop or section.

Integrated automation is a stage of production automation in which the entire set of material processing operations, including their transportation, is carried out through a system of automatic machines and technologies, units according to predetermined programs and modes, using various automatic devices united by a common management system.

With complex automation, human functions in the control of the technological process are reduced to monitoring the course of the process, analyzing its indicators and choosing the operating modes of the equipment as a set of tasks for automatic regulators and software devices in which the best indicators are achieved under these conditions.

The most easily integrated automation is carried out in continuous production, processes, separate sections of which are forcibly connected through a single material flow.

An example of complex process automation is an automatic line, in which each automatic machine, using a software device, performs a predetermined sequence of movements of its working organs to carry out a given phase of material processing, and the entire set of linear machines connected by automatically operating transport devices — a general sequence of processing phases until receiving the finished product.

Fully automated businesses are all Power plant (Nuclear power plant, thermal power plant, hydroelectric plant). The management of the main electrical and mechanical equipment in these stations is carried out automatically, and control over its operation is concentrated, as a rule, at one point, from where the shift dispatcher sets the necessary modes.

Operational management must be centralized and concentrated in the hands of one person. The need for such centralization is due to the fact that in order to make a decision on the choice of modes of individual technological units, a complete picture of the entire production, process, that is, the processing of all information coming from all sections of the process, is needed.

Therefore, among control systems, devices occupy a prominent place, the task of which is to organize communication between man and machines, to make it easier for a person to control processes, to relieve his nervous system, to free the brain from stressful and routine work.

In addition, a person often cannot process a large flow of information about the progress of processes without the help of additional devices.

For example, in the conditions of centralized management of branched power systems, the functions of the dispatcher of the central control point become increasingly complex, and decision-making, as a rule, is carried out under conditions of acute shortage of time. All this requires the rapid collection of diverse information to show a person in the form of an easily noticeable result, necessary for decision-making.

With centralized control, all production and process status information is centralized with shift dispatchers or operators.

To convey information to a person, there are numerous indicating and recording devices located on the control center boards in front of the operator or dispatcher. In addition to devices, the control room has technical devices that allow you to monitor various critical areas of production.

The photo shows the control room. It is the vertical panel(s) on which they are located mnemonic schemes controlled industries, processes, measuring instruments and various alarm indicators and panels of automatic control devices, sometimes also remote control keys and buttons.

Since in enterprises and industries with a large territory, the exchange of information between the objects of control and management and the dispatch center is carried out with the help of technical means of telemechanics, devices for reproducing these systems are placed on the dispatch panel.

A person controlling a process based on his knowledge of its properties and characteristics uses extensive foresight and is therefore able to significantly improve process control. In the narrow framework of this process, knowledge is a model of the process in the human brain.

Before choosing one or another control action, a person, using this "model", speculatively checks what the results of the actions will be on the output parameters of the process.

Only after being convinced that this influence will force the process to change in the desired direction or to keep its course unchanged, one transfers this influence to the real process, constantly comparing its course with the speculative results obtained and refining the model.

Similar to how a human does it, an automatic predictive control system can work. Such a system should have a process model, devices that provide self-tuning of the model parameters to match the actual process, and a device that automatically searches the model for such control actions that provide the best process performance. Detected influences should be automatically transferred to the actual process.

An example of a complex automatic control system is a continuous furnace for heating the material, equipped with temperature regulators in the working space and regulators of the flow of fuel and air supplied to the furnace burners.

The heating of the material leaving the furnace is determined by the temperature of its working space, the speed of movement of the material and a number of other factors. In turn, the temperature of the working space is determined by the amount of fuel consumption and the ratio of fuel - air consumption, and also depends on the speed of movement of the heated material.

The material temperature maintenance problem in this example cannot be solved by installing separate, unrelated temperature and flow controllers.

It is necessary that the reference to the temperature controller in the furnace increases automatically as the speed of movement of the material in the furnace increases, and the reference to the air flow controller increases as the fuel consumption increases.

Difficult tasks also arise in the creation of systems for controlling processes with multiple energy conversions. An example of blast furnace smelting. Here, the control law establishes a set of required values of individual process parameters (temperature, pressure, flow rate, etc.), each of which is affected by many disturbances caused by factors external and internal to that process.

The success of integrated automation of existing production areas is determined almost entirely by the compliance of existing equipment and technology with the requirements for automatic control.

The equipment of most operating enterprises is designed for manual control.Therefore, complex automation, as a rule, must be accompanied by modernization or complete replacement of equipment, a change in technology and organization of production, in which the possibilities of automatic control in terms of speed and accuracy would be fully used.

The complete automation of any production area must be preceded by a thorough technical and economic analysis of the entire set of measures to determine economic efficiency. Full automation allows you to centralize production and process management, reduce personnel, increase equipment productivity, improve product quality, and reduce costs.

For complex processes, the centralization of management requires the use of automatic management systems that allow collecting information about the progress of a controlled process and transmitting it to a person in a form convenient for him.

Integrated automation is a step towards full automation, ending with the creation of workshops and automatic factories.

Full automation

Full automation is a stage of production automation in which a system of automatic machines performs, without direct human participation, the entire range of operations of a given production, process, including the selection and establishment of work modes that provide the best performance in given conditions .

The duties of a person are reduced to monitoring the proper functioning of the management system and its individual units, as well as introducing tasks and criteria into this system that the process must satisfy.

For simple processes running under constant conditions, once selected and adjusted, the optimal mode can be maintained for a long time, and the concept of full automation coincides with the concept of complex automation.

For most processes subject to external disturbances, the main difference between full automation and complex automation is the transfer of the function of selecting and coordinating the operating modes of individual machines and units (including in emergency situations) from a person to an automatic control system.

The basis for the transition to full automation is the automatic search and establishment of optimal equipment operating modes and the automation of operational management, that is, the coordination of the modes of individual machines and units.

To solve these problems, computer technologies are widely used, in particular control machines (controllers, industrial computers), analyzing the course of production, the process, synthesizing the control laws and determining the optimality criteria. The automatic analysis of the technological flow and the synthesis of the control laws predetermine the self-adaptability of the systems for full automation.

Full automation systems have a hierarchical construction principle:

- At the 1st stage, there are software and logical control systems, as well as automatic control systems;

- on the 2nd stage — systems for automatic optimization of individual machines and aggregates;

- on the 3rd stage — automatic systems for operational management.

The three-level control hierarchy defines the functional structure of full automation systems.The hardware resolution of this system can be different, the system can be built as shown above, but it can be built without a clear separation of the functions performed by individual devices.

The growing complexity of the control tasks leads to an increase in the number and complexity of the equipment and, as a result, to an increase in the probability of disrupting the normal operation of the system.

The continuous intensification of processes and the increase in their scale and the correspondingly increasing threat of accidents make the problem of reliability even more important in the automation of production. Therefore, more and more reliable elements and methods for their connection are being developed, as well as methods for building reliable systems from insufficiently reliable elements are being sought.

The full automation system is a complex and branched automatic control system, which requires its high reliability, provided by both the reliability of individual elements and the reliability of the structure.

The task of full automation is the creation of automatic workshops and enterprises (automatic factories). The great economic effect of full automation is achieved by improving the use of equipment, ensuring the rhythm of the process with optimal productivity and product quality under the given conditions.

Look: Automation of technological processes, Industrial robots in modern production, Automation of power supply management systems

The development of automatic control technology is impossible without progress in equipment and especially in those elements from which control devices are built.The most important problem in the development of automatic control equipment and systems is increasing their reliability.