How is the cable insulation test performed?

The quality of the insulation layer of the cable significantly affects the reliability of the electrical installation as a whole. It can change both during production in the factory and during storage, transportation, installation of the circuit and especially during its operation.

The quality of the insulation layer of the cable significantly affects the reliability of the electrical installation as a whole. It can change both during production in the factory and during storage, transportation, installation of the circuit and especially during its operation.

For example, moisture trapped in the insulation will freeze at negative temperatures and change its conductive properties. Determining its presence in this situation is very problematic.

Types of checks

Attention is constantly paid to the quality of the insulation, which is applied comprehensively:

-

periodic mandatory inspections by trained personnel;

-

automatic tracking by special control devices during the execution of a continuous technological cycle.

During cable evaluation, personnel determine its mechanical condition and check its electrical characteristics.

During an external inspection, which is mandatory in any inspection, quite often you can see only the ends of the cable taken out for connection, and the rest of it is hidden from view. But even with full access, it is impossible to determine the quality of the insulation layer.

Electrical checks allow you to identify all insulation defects, which allows you to draw a conclusion about the suitability of the cable for further work and give guarantees for its use. According to the degree of complexity, they are divided into:

1. measurements;

2. tests.

The first method is used for quality assessment in the following cases:

-

after purchase, before the start of laying in an electrical circuit, so as not to waste time laying and subsequent disassembly of a defective cable;

-

after completion of the installation works, to assess their quality;

-

when the tests are over. This makes it possible to assess the performance of the insulation exposed to overvoltage;

-

periodically during operation to control the safety of technical characteristics under the influence of operating current loads or environmental factors.

Cable insulation tests are performed after installation, before connection to work, or periodically during work, if necessary.

How the cable works

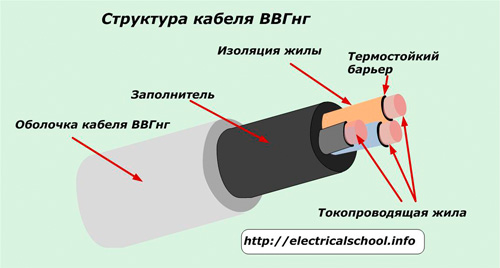

To explain the principle of electrical checks, let's look at the structure of a simple, common VVGng brand cable.

Each of its live conductors is equipped with its own layer of dielectric coating, which isolates it from neighboring conductors and ground leakage. Live conductors are enclosed in a filler and protected by a sheath.

In other words, each electric cable consists of metal conductors, most often based on copper or aluminum, and an insulating layer that protects the conductors from the occurrence of leakage currents and short circuits between all phases and ground.

Each cable is designed to transmit a certain type of energy under different operating conditions. Certain, specific requirements are imposed on it, agree PUE… They should be familiar with them before making electrical measurements.

Testing devices

Sometimes novice electricians use testers or multimeters to measure the insulation of a cable or wiring, on which a scale is applied to measure resistance in kilohms and megohms. This is a gross mistake. Such devices are designed to evaluate the parameters of radio components, they work on low-power batteries. They are not able to create the necessary load on the insulation of cable lines.

These purposes are served by special devices - megometers, called "megohmmeter" in the jargon of electrical engineers. They have many designs and modifications.

Before using any device, it is necessary to check its operability each time:

-

external review;

-

estimation of the time of passing the checks by the metrology laboratory according to the state of its seal on the case. Safety rules do not allow the use of a measuring device with a broken stigma, even when there is a passport for the check carried out before the end of its validity;

-

checking the timing of periodic insulation tests in the high-voltage part of the device by an electrical laboratory.A defective megohmmeter or damaged connecting wires can cause electric shock to personnel.

-

control measurement of known resistance.

Attention! All work with a megohmmeter is classified as dangerous! They can only be performed by trained, tested and approved personnel with electrical safety group III and higher.

Technical issues in the preparation of cables for measurement and insulation testing

Please note that the organizational part is described here very briefly and incompletely. This is a big, important topic for another article.

1. All measurement work should be done on vented cable and normally on the surrounding equipment. The effect of induced electric fields on the measuring circuit must be excluded.

This is dictated not only by safety, but also by the principle of operation of the device, which is based on supplying a calibrated voltage to the circuit from its own generator and measuring the currents that arise in it. The scale divisions of analog instruments and the readings of digital models in ohms are proportional to the magnitude of the leakage currents occurring.

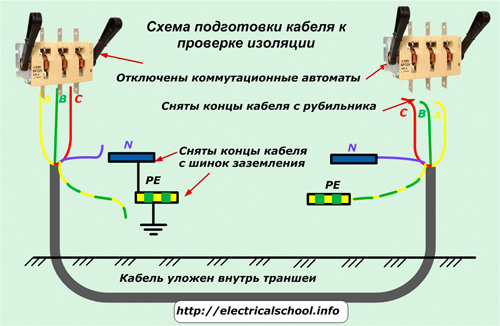

2. The cable connected to the equipment must be disconnected from all sides.

Otherwise, the insulation resistance will be measured not only on its core, but also on the rest of the connected circuit. Sometimes this technique is used to speed up work. But in any case, in order to obtain reliable information, the connection scheme of the equipment must be taken into account.

To disconnect the cable, its ends are not pierced or the switching devices to which it is connected are turned off.

In the second case, when negative results are obtained, it is necessary to check the insulation of the circuits of these devices.

3. The length of the cable can reach a large value of the order of a kilometer. At the farthest end, at the most unexpected moment, people can appear and with their actions affect the result of the measurement or suffer from a high voltage applied to the cable of a megohmmeter. This should be prevented by implementation organizational conditions.

Features of safe use of megohmmeter and measurement technology

Long cables laid in electrical networks near workers high voltage equipment, can be under induced voltage, and when disconnected from the ground loop, have a residual charge, the energy of which can harm the human body. The megohmmeter generates a surge voltage that is applied to the cable conductors that are insulated from ground. In this case, a capacitive charge is also created: each core acts as a capacitor plate.

Both of these factors together make it a safety condition that a portable ground be used when measuring the resistance of each core, both individually and as a complex. Without it, touching the metal parts of the cable without the use of electrical protective equipment is strictly prohibited.

How to measure the insulation resistance of wires to ground

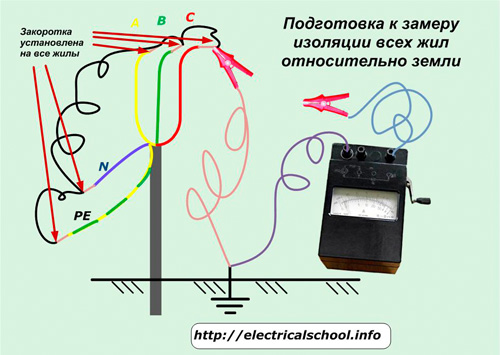

Consider as an example checking the insulation resistance of a single core to ground.

The first end of the portable ground is first firmly attached to the ground loop and is no longer removed until all electrical checks have been completed.One of the two megohmmeter leads is also connected here.

The other end of the ground, provided with an insulated pin with a protective ring and a quick-connecting clip of the "Crocodile" type, in compliance with the safety rules, is connected to the metal core of the cable to remove the capacitive charge from it. Then, without removing the ground, the output of the second wire from the megohmmeter is also switched here.

Only then is it allowed to remove the "crocodile" grounding for measurements by applying voltage to the prepared electrical circuit. The measurement time must be at least one minute. This is necessary to stabilize circuit transients and obtain accurate results.

When the megohmmeter generator is stopped, it is impossible to disconnect the device from the circuit due to the capacitive charge present on it. To remove it, it is necessary to reuse the second end of the portable ground, place it on the tested core.

The lead coming from the megohmmeter is removed from the core after a portable ground is connected to it. Thus, the circuits of the measuring device are always switched to the test circuit only when the mass is installed, which is removed during the measurement.

The described test of the insulation condition of the cable with a megohmmeter for phase C is demonstrated by the sequence of figures.

In the given example, in order to simplify the understanding of the technology, actions with other wires that remain under induced voltage are not described, which must be removed by installing a short circuit with additional portable grounding, which greatly complicates the circuit and measurements.

In practice, in order to speed up the work of checking the phase isolation to earth, all cable cores are short-circuited. This operation must be performed by authorized personnel. She is dangerous.

In the example under consideration, these are the phases PE, N, A, B, C. Then measurements are made using the above technology for all parallel-connected circuits at once.

Usually the cables are operated in good condition, then such a check is sufficient. If you get an unsatisfactory result, then you will have to carry out all the measurements in stages.

How to measure insulation resistance between cable conductors

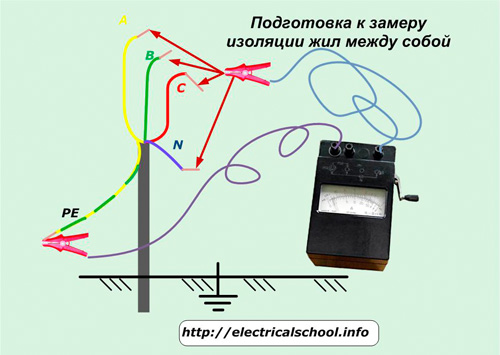

To better understand the process, let's simplify that the cable is not affected by induced voltage and has a short length that does not create significant capacitive charges. This will allow you not to describe the actions with portable grounding, which must be carried out according to the already considered technology.

Before measuring, it is necessary to check the assembled circuit and check with an indicator that there is no voltage on the veins. They must move apart without touching each other and the surrounding objects. The megohmmeter is connected at one end to the phase against which the measurement will be made, and the remaining phases are alternated in series with the second wire for measurements.

In our example, the insulation of all cores is measured in turn against the PE phase. When it is finished, then we choose for the next common phase, for example N. In the same way, we make measurements against it, but we no longer work with the previous phase. Its insulation between all cores is checked.

Then we select the next phase as common and continue the measurements with the remaining veins. In this way, we arrange all possible combinations of connection of the wire with each other in order to analyze the state of their insulation.

Once again, I would like to draw your attention to the fact that this test is described for a cable that is not subjected to induced voltage and does not have a large capacitive charge. It is impossible to copy it blindly for all possible cases.

How to document measurement results

The date and scope of the inspection, information about the composition of the team, the measuring devices used, the connection diagram, the temperature regime, the conditions for performing the work, all the obtained electrical characteristics must be stored in the protocol. In the future, they may be needed for a working cable and serve as evidence of a malfunction of a rejected product.

Therefore, a protocol is drawn up for the measurements carried out, certified by the signature of the manufacturer of the work. For its design, you can use an ordinary notebook, but it is more convenient to use a pre-prepared form containing information on the sequence of operations, reminders of safety measures, basic technical standards and tables prepared for filling.

It is convenient to compile such a document after using a computer, and then simply print it on a printer.This method saves time for preparation, registration of measurement results, gives the document an official look.

Characteristics of insulation tests

This work is carried out using special stands containing external sources of increased voltage with measuring devices, belongs to the category of dangerous. It is carried out by specially trained and authorized personnel who are organizationally part of a separate laboratory or office in the enterprises.

The testing technology is very similar to the insulation measurement process, but more powerful energy sources and highly accurate measuring instruments are used.

The results of the tests, as well as the measurements, are recorded in a protocol.

Insulation monitoring devices

Much attention is paid to the automatic inspection of the insulation condition of electrical equipment in the power industry. It can greatly improve the power reliability of users. However, this is a separate big topic that requires further disclosure in another article.