Thermistor (posistor) protection of electric motors

The protection of asynchronous electric motors against overheating is traditionally implemented on the basis of thermal overcurrent protection. In the majority of operating motors, thermal protection against overcurrent is used, which does not accurately take into account the actual operating temperature regimes of electric motors, as well as its temperature constants over time.

In indirect thermal protection of an induction motor bimetallic plates include in the supply circuit of the stator windings of an asynchronous electric motor, and when the maximum permissible stator current is exceeded, the bimetallic plates, when heated, turn off the stator supply from the power source.

The disadvantage of this method is that the protection does not respond to the heating temperature of the stator windings, but to the amount of heat released, without taking into account the time of operation in the overload zone and the actual cooling conditions of the induction motor.This does not allow full use of the overload capacity of the electric motor and reduces the performance of equipment operating in intermittent mode due to false shutdowns.

Complexity of construction thermal relays, insufficiently high reliability of protective systems based on them led to the creation of thermal protection that responds directly to the temperature of the protected object. In this case, temperature sensors are mounted on the motor winding.

Temperature-sensitive protective devices: thermistors, posistors

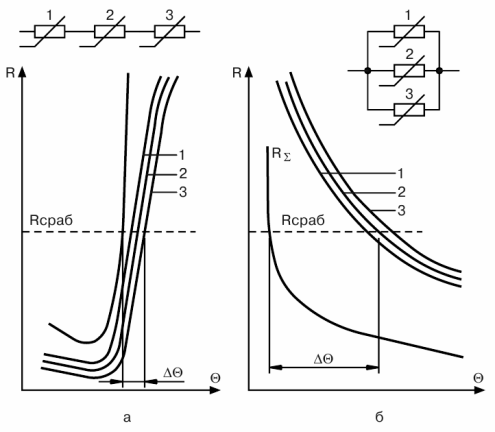

By using temperature sensors thermistors and positrons — semiconductor resistors that change their resistance with temperature…. Thermistors are semiconductor resistors with a large negative TSC. As the temperature increases, the resistance of the thermistor decreases, which is used for the motor shutdown circuit. To increase the slope of the resistance versus the temperature dependence, thermistors glued to three phases are connected in parallel (Figure 1).

Figure 1 — Dependence of the resistance of posistors and thermistors on temperature: a — series connection of posistors; b — parallel connection of thermistors

Posistors are nonlinear resistors with a positive TCK. When a certain temperature is reached, the resistance of the posistor increases sharply by several orders of magnitude.

To enhance this effect, posistors of different phases are connected in series. The characteristics of the posistors are shown in the figure.

The protection through positors is more perfect. Depending on the insulation class of the motor windings, reaction temperature positions = 105, 115, 130, 145 and 160 are taken.This temperature is called the classification temperature. The posistor changes its resistance sharply at temperature in no more than 12 s. When the resistance of three series-connected posistors should be no more than 1650 ohms, at temperature their resistance should be at least 4000 ohms.

The guaranteed service life of the posistor is 20,000 hours. Structurally, the posistor is a disk with a diameter of 3.5 mm and a thickness of 1 mm, covered with organic silicon enamel, which creates the necessary moisture resistance and electrical strength of the insulation.

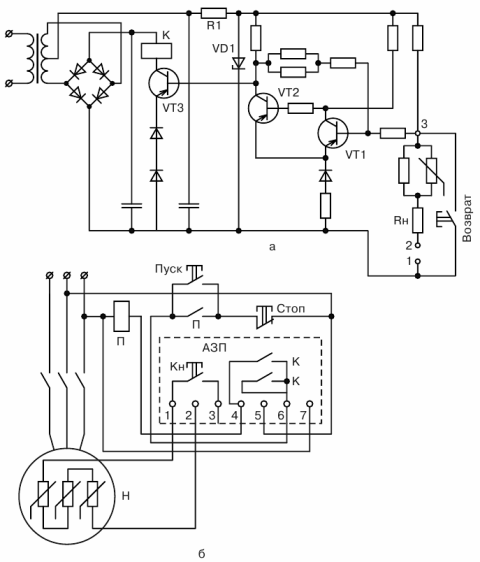

Consider the PTC protection circuit shown in Figure 2.

Figure 2 — Apparatus for protecting positors with manual return: a — schematic diagram; b — connection diagram to the motor

Contacts 1, 2 of the circuit (Figure 2, a) are connected to the posistors mounted on the three phases of the motor (Figure 2, b). Transistors VT1, VT2 are turned on according to the Schmid trigger circuit and operate in key mode. The output relay K is connected to the collector circuit of the final stage transistor VT3, which acts on the starter winding.

At normal temperature of the winding of the motor and its associated positors, the resistance of the latter is small. The resistance between points 1-2 of the circuit is also small, the transistor VT1 is closed (based on a small negative potential), the transistor VT2 is open (high potential). The negative potential of the collector of the transistor VT3 is small and closed. In this case, the current in the coil of the relay K is insufficient for its operation.

When the motor winding is heated, the resistance of the positors increases, and at a certain value of this resistance, the negative potential of point 3 reaches the trigger voltage. The relay operation mode is provided by emitter feedback (resistance in the emitter circuit VT1) and collector feedback between the collector VT2 and the base VT1. When the trigger is actuated, VT2 closes and VT3 opens. Relay K is activated, closing the signal circuits and opening the starter electromagnetic circuit, after which the stator winding is disconnected from the mains voltage.

After the engine has cooled down, it can be started after pressing the «return» button, which returns the trigger to its initial position.

In modern electric motors, the protective positors are mounted in front of the motor windings. On older motors, the posistors may be glued to the coil head.

Advantages and disadvantages of thermistor (posistor) protection

Thermosensitive protection of electric motors is preferable in cases where it is impossible to determine the temperature of the electric motor with sufficient accuracy from the current. This applies in particular to electric motors with long starting periods, frequent switching on and off operations (periodic operation) or variable speed motors (with frequency converters). The thermistor protection is also effective in case of heavy contamination of electric motors or failure of the forced cooling system.

The disadvantages of thermistor protection are that not all types of electric motors are manufactured with thermistors or posistors.This is especially true for domestically produced electric motors. Thermistors and posistors can be installed in electric motors only in stationary workshops. The temperature characteristic of the thermistor is quite inertial and strongly depends on the ambient temperature and the operating conditions of the electric motor itself.

Thermistor protection requires a special electronic block: a thermistor protection device for electric motors, a thermal or electronic overload relay, which contains adjustment and adjustment blocks, as well as output electromagnetic relays, which are used to turn off the starter coil or electromagnetic release.