How to protect the metal sheaths of cables from corrosion

The metal sheaths of the cables during their operation are destroyed as a result of chemical (soil corrosion) or electrochemical interaction with the environment.

Exposed cables are sufficiently reliably protected from the corrosive effects of the ambient air by applying a layer of varnish or paint to the armor or sheath.

The intensity of soil corrosion, depending on the composition and moisture content of the soil, can be estimated by the value of the electrical resistance of the soil. Soils with high electrical resistance (resistance more than 20 Ohm per meter) do not cause severe corrosion, so when designing, they tend to choose a route of a cable line that has a low corrosive soil.

Sources and causes of corrosion of metal cable sheaths

The most dangerous source of corrosion for cable lines is electrified railway transport, tram, subway, where rails are used as conductors.

For example, the wire of the city tramcar is fed from the positive pole of the traction substation.The negative pole is connected by cable lines to various points on the track which are called suction points.

The return currents of the tram network flow along the rails to the suction points. Since the rails are not insulated from ground, the current passing through them is partially branched into the ground and follows the path of least resistance to the location of the suction points. If in the zone of action of these currents there are cable lines whose metal sheaths are good conductors, then stray currents from the ground pass into the sheaths of the cables and form a cathode zone with a negative potential, and near the suction points they leave them and form an anode zone with positive potential.

The return currents of the tram network flow along the rails to the suction points. Since the rails are not insulated from ground, the current passing through them is partially branched into the ground and follows the path of least resistance to the location of the suction points. If in the zone of action of these currents there are cable lines whose metal sheaths are good conductors, then stray currents from the ground pass into the sheaths of the cables and form a cathode zone with a negative potential, and near the suction points they leave them and form an anode zone with positive potential.

Corrosion of cable sheaths occurs in the anode zone, because it is here that oxygen is released, which oxidizes and corrodes the metal of the cable sheath.

Zoning is done by measuring the potential on the cable sheaths relative to ground. A positive potential indicates the presence of an anodic zone, a negative potential indicates a cathodic zone.

For armored power cables with lead sheaths laid in low-active soils (resistance more than 20 Ohm per meter), the average daily ground leakage current density should not exceed 14 mA / m2. Otherwise, measures are necessary to protect the cable sheaths from corrosion. For bare lead cables, the anode areas are considered hazardous regardless of the leakage current density.

Methods of protecting metal sheaths of cables from corrosion and stray currents

In order to protect the metal sheaths of cables from stray currents, in addition to eliminating violations in the implementation and operation of rail and suction networks of electrified transport, cathodic polarization, electrical drainage and protector protection are used.

In order to protect the metal sheaths of cables from stray currents, in addition to eliminating violations in the implementation and operation of rail and suction networks of electrified transport, cathodic polarization, electrical drainage and protector protection are used.

Cathodic polarization

Cathodic polarization means that a negative potential is created on the cable sheath by an external source which prevents current from the rails to the cable sheath

Electrical drainage

Electrical drainage consists of diverting the stray currents from the metal sheaths of the cables to the source of these currents.

Protective protection

The protective shield provides the connection of metal cable sheaths with a magnetic alloy electrode embedded in the ground and having a higher potential (about 1.5 V) than the cable sheaths. The current generated by the potential difference is enclosed between the protector (electrode) and the sheath of the cable. The protection zone of the tread is about 70 m.

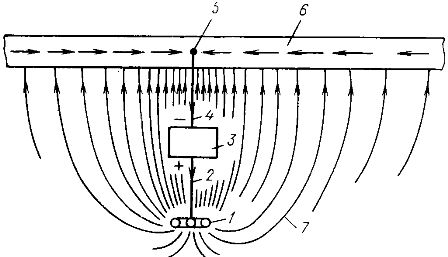

Scheme of cathodic protection of the metal sheath of the cable against corrosion: 1 — anode grounding, 2 — wire, 3 — direct current source (cathode station), 4 — wire, 5 — drain point (contact node), 6 — cable sheath , 7 — electromagnetic power lines.

Scheme of cathodic protection of the metal sheath of the cable against corrosion: 1 — anode grounding, 2 — wire, 3 — direct current source (cathode station), 4 — wire, 5 — drain point (contact node), 6 — cable sheath , 7 — electromagnetic power lines.