Detection of defects in the contact connections of switchgear and overhead lines

As you know, depending on the design, purpose, method of connection of materials, field of application and other factors, there are contact joints with bolts, welded, soldered and crimped (pressed and twisted). Remote spacer wires can also refer to contact connections.

Defects of welded contact joints

During work in contact joints made by welding, the causes of defects can be: deviations from the specified parameters, undercuts, bubbles, caves, lack of penetration, sagging, cracks, slag and gas inclusions (cavities), unsealed craters, burning of the core wires, divergence of the connected wires, wrong choice of terminals, lack of protective coatings on the connections, etc.

Thermal welding technology does not ensure reliable operation of welded connectors for wires with a large cross-section (240 mm2 and more).This is due to the fact that due to insufficient heating during welding of the wires to be connected and uneven convergence of their ends, the outer layers are burned, the lack of penetration, shrinking voids and slags appear at the welding site . As a result, the mechanical strength of the welded connection decreases, which, at mechanical loads lower than calculated, leads to a break (burning) of the wire in the loop of the anchor.

Welding defects in anchor support loops have led to emergency shutdowns of short-lived overhead lines. If the individual wires break in the welded joint, this leads to an increase in the contact resistance and its temperature. The rate of development of defects in this case will depend significantly on a number of factors: the value of the load current, the wire voltage, the effect of wind and vibration, etc. Based on the experiments conducted, it was found that:

-

reduction of the active cross-section of the conductor by 20 — 25% due to breakage of individual conductors may not be detected during IR control from a helicopter, which is associated with the low emissivity of the conductor, the distance of the heat insulator from the track at 50 — 80 m, the influence of wind, solar radiation and other factors;

-

when rejecting defective contact joints made by welding, using a thermal imager or pyrometer, it should be borne in mind that the rate of development of defects in these joints is much higher than in bolted contact joints with pressing;

-

defects of contact joints made by welding at an excess temperature of about 5 ° C, detected by a thermal imaging camera during inspection by an overhead line helicopter, should be classified as dangerous;

-

steel sleeves that are not removed from the welded portion of the wires may give a false impression of possible heating, due to the high emissivity of the heated surface.

Defects of pressed contact connections

In the contact connections made by crimping, there are improper selection of lugs or sleeves, incomplete insertion of the core into the lug, insufficient pressing, displacement of the steel core in the wire connector, etc. As you know, one of the ways to manage the crimped connectors is to their DC resistance was measured.

The criterion for the minimum contact connection is the resistance of the equivalent section of the entire conductor. A molded connector is considered advantageous if its resistance is no more than 1.2 times the equivalent length of the entire wire.

The criterion for the minimum contact connection is the resistance of the equivalent section of the entire conductor. A molded connector is considered advantageous if its resistance is no more than 1.2 times the equivalent length of the entire wire.

When the clutch is pressed, its resistance drops sharply, but with increasing pressure it stabilizes and changes insignificantly. The resistance of the connector is very sensitive to the condition of the contact surface of the crimped wires. The appearance of aluminum oxide on the contact surfaces leads to a sharp increase in the contact resistance of the connector and an increase in heat generation.

The insignificant changes in the contact resistance of the contact joint during the pressing process, as well as the associated low heat release in it, indicate the insufficient efficiency in detecting defects in them immediately after assembly with the help of infrared devices.

During the operation of pressed contact joints, the presence of defects in them will contribute to more intensive formation of oxide films with an increase in transient resistance and the occurrence of local overheating. Therefore, it can be assumed that infrared control of new crimped contact connections does not allow the detection of crimp defects and should be performed for connectors that have been in operation for a certain period (1 year or more).

The main characteristics of molded connectors are the degree of crimp and mechanical strength. As the mechanical strength of the connector increases, its contact resistance decreases. The maximum mechanical strength of the connector corresponds to the minimum electrical resistance of the contact.

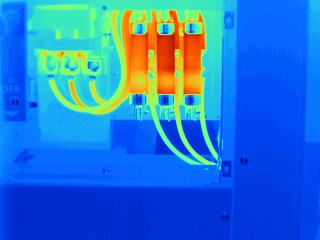

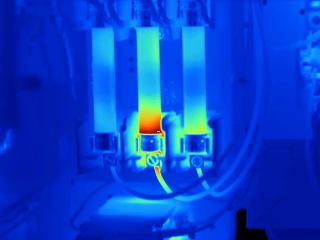

Defects of bolted contact connections

Contact connectors made with bolts most often have defects due to the lack of washers when connecting a copper wire to a flat terminal made of copper or aluminum alloy, the lack of Belleville springs, due to the direct connection of the aluminum tip to the copper terminals of indoor equipment with an aggressive or wet environment, as a result of insufficient bolt tightening torque, etc.

Bolted contact joints of aluminum busbars for high currents (3000 A and more) do not have sufficient stability in operation.If contact connections for currents up to 1500 A require tightening of bolts every 1-2 years, then similar connections for currents of 3000 A and more need annual repair, with the necessary cleaning of the contact surfaces. The need for such an operation is due to the fact that in pipelines for large currents (buses of power plants, etc.) made of aluminum, the process of formation of oxide films on the surface of the contact joints is more intense.

The process of formation of oxide films on the surface of bolted contact joints is facilitated by different temperature coefficients of linear expansion of steel bolts and aluminum rail. When short-circuit current or alternating current passes through the busbar, vibrations occur, especially when the busbar is long, and deformation (compaction) of the contact surface of the aluminum busbar occurs. In this case, the force that pulls the two contact surfaces of the bus together weakens and the layer of lubricant between them evaporates. As a result of the formation of oxide films, the contact area of the contacts, i.e. the number and size of the contact areas (points) through which the current passes decrease, and at the same time the current density in them increases. It can reach thousands of amperes per square centimeter, as a result of which the heating of these points increases significantly.

The temperature of the latter point reaches the melting point of the contact materials and a drop of liquid metal forms between the contact surfaces. The temperature of the droplets, increasing, reaches boiling, the space around the contact junction is ionized, and a multiphase short circuit can form in the reactor plant.Under the influence of magnetic forces, the arc can move tires RU with all the resulting consequences.

Operational experience shows that, along with high-current busbars, single-bolt contact connections have insufficient reliability. The latter, in accordance with GOST 21242-75, are allowed to be used at rated currents up to 1000 A, but they are damaged already at currents of 400-630 A. Improving the reliability of single-bolt contact connections requires a number of technical measures to stabilize the electrical their resistance.

The process of development of defects in a bolted contact connection, as a rule, takes a long time and depends on a number of factors: load current, mode of operation (stable load or variable), exposure to chemicals, wind load, bolt tightening forces, availability of contact pressure stabilization, etc.

The contact resistance of the contact connection gradually increases until a certain point in time, after which there is a sharp deterioration of the contact surface with intense heat release, which characterizes the emergency state of the contact connection.

Similar results were obtained by specialists from Inframetrix (USA) during thermal tests of bolted contact joints. The increase in the heating temperature during the tests is gradual throughout the year, and then a period of sharp increase in heat release begins.

Defects of contact joints made by twisting

Damage to contact connections made by twisting occurs mainly due to installation defects.Incomplete twisting of wires in oval connectors (less than 4.5 turns) will pull the wire from the connector and break it. Untreated wires create a high contact resistance, resulting in the wire in the connector overheating with possible burnout. There are cases of repeated pulling of lightning protection wire of the type AJS-70/39 from oval connector of the brand SOAS-95-3 from 220 kV overhead lines twisted at a lower number of turns.

Distance brackets

Distance brackets

The unsatisfactory design of some versions of spacers, exposure to vibration forces and other factors can lead to chafing or breakage of wires. In this case, a current will flow through the spacer, the value of which will be determined by the nature and degree of development of the defect.

Based on the materials "Infrared diagnostics of electrical equipment of distribution devices" Author Bazhanov S. A.