Causes of damage to the heating elements of electric furnaces

Life heating elements depends on a number of factors: on the operating temperature, the nature of its change over time, the design and size of the heater, the effect of the furnace atmosphere on it. It can be caused by the gradual oxidation of the working material (or by its pulverization, if we are talking about precious metals or heaters operating in a vacuum or in a protective atmosphere) or a loss of mechanical strength.

Life heating elements depends on a number of factors: on the operating temperature, the nature of its change over time, the design and size of the heater, the effect of the furnace atmosphere on it. It can be caused by the gradual oxidation of the working material (or by its pulverization, if we are talking about precious metals or heaters operating in a vacuum or in a protective atmosphere) or a loss of mechanical strength.

The materials used for heaters, when heated, form dense oxide films that protect the base material from further oxidation, therefore, up to certain (for each material) temperatures, oxidation develops extremely slowly, and after passing through this temperature level, the process accelerates sharply. Spraying materials in a vacuum or protective atmosphere also proceeds in the same way.

The maximum allowable temperature of a material should be the temperature at which the oxidation or dispersion process of the material increases sharply. If you exceed this level, the life of the heating element is significantly reduced.

When the heater oxidizes, the oxide film on it (usually non-conductive or low-conductive) gradually thickens and the cross-section of the metal core decreases. Therefore, the resistance of the heater gradually increases, and the power released in it decreases. When this reduction in power becomes significant (about 10-15%), the heater must be replaced with a new one, its service life ends.

When the heater oxidizes, the oxide film on it (usually non-conductive or low-conductive) gradually thickens and the cross-section of the metal core decreases. Therefore, the resistance of the heater gradually increases, and the power released in it decreases. When this reduction in power becomes significant (about 10-15%), the heater must be replaced with a new one, its service life ends.

The gradual process of increasing the resistance of the heater as a result of its oxidation or scattering is not always the reason for its replacement; very often the heater fails long before its resistance reaches its limiting value. The heater usually has several weakened areas, small cracks at the bends, inclusions of oxide films and the like, where a local increase in resistance is observed.

Such areas of increased resistance will cause local overheating in the heaters and more intensive oxidation at the places of this overheating. Intense oxidation, in turn, will lead to a further decrease in the cross-section of the heater at these points, a further increase in their temperature, the process will continue at an increasing rate and will lead to the heater burning out at one of these points.

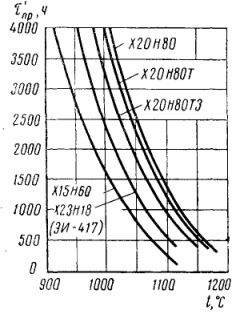

Service life of a 1 mm wire heater depending on its temperature (in air)

A similar effect can occur if the surface of the heater is dirty or incorrectly designed, if heat transfer to some of its parts is difficult (for example, in the parts of the heater shielded with refractory supports or hooks), resulting in local overheating .

This type of local overheating will not significantly affect the reduction of the service life of the heater in cases where their absolute values are low and the temperatures of the hottest zones will not reach the values at which intensive oxidation (or scattering) of the material begins.

Therefore, it is necessary to strive to ensure that there is a certain limit between the operating temperature of the heater and its maximum allowable heating temperature, which exceeds the value of possible local overheating. If this margin is small, then these local overheatings must be minimized by rational design and the choice of large cross-sections of the heater, since the larger these cross-sections, the smaller the percentage of local constrictions, the more less local will have overheating.

The reason for the failure of the heater can also be its insufficient mechanical strength at high temperatures, its tendency to creep or warp.For example, if the heater is designed in such a way that at operating temperature it begins to deform under its own weight (pulling the heater loops hanging on the hooks, warping the heater coils), then adjacent turns or loops can close , arcs in these places and, as a result, burn out the heater or simply local thinning of the section as a result of stretching with the formation of local overheating again.

The reason for the failure of the heater can also be its insufficient mechanical strength at high temperatures, its tendency to creep or warp.For example, if the heater is designed in such a way that at operating temperature it begins to deform under its own weight (pulling the heater loops hanging on the hooks, warping the heater coils), then adjacent turns or loops can close , arcs in these places and, as a result, burn out the heater or simply local thinning of the section as a result of stretching with the formation of local overheating again.

Finally, the heater can be damaged by chemical interaction at operating temperature with the lining materials. electric ovenwith which he comes in contact or with its atmosphere.

The performance of any material in the heating elements of an electric resistance furnace can be characterized by two temperatures—the recommended operating temperature and the maximum allowable temperature.

The maximum permissible temperature of the material corresponds to the temperature limit beyond which its intense oxidation or spattering begins and, accordingly, a sharp reduction in service life. The recommended temperature is below the maximum allowed.

In the area limited by the recommended material temperature, the service life of the heater is quite long, for metal alloys about 12000-15000 hours. In this area, limited local overheating is not terrible, because even with their significant sizes, the temperature of the heater will not exceed the maximum permissible value. Small heater cross-sections can therefore be used at such temperatures.Naturally, in all cases where possible, heaters should be designed in such a way that their design temperature does not exceed the recommended one.