Dielectric Protective Equipment: Testing of Dielectric Gloves, Overshoes and Boots

Rubber dielectric protectors

Among the means that protect personnel from electric shock, the most common are dielectric gloves, galoshes, boots and carpets. They are made of rubber with a special composition with high electrical strength and good elasticity. However, special rubber is also destroyed by heat, light, mineral oils, gasoline, bases, etc., and is easily damaged mechanically.

Dielectric gloves

Dielectric gloves are produced in two types:

- dielectric gloves for electrical installations up to 1000 V, in which they are used as the main protective equipment when working under voltage. These gloves should not be used in electrical installations above 1000 V;

- dielectric gloves for electrical installations above 1000 V, in which they are used as an additional protective means when working with the main insulating protective means (rods, high voltage indicators, insulating and electrical measuring clamps, etc.).In addition, these dielectric gloves are used without the use of other protective equipment during operations with disconnector drives, switches and other equipment with voltages above 1000 V.

Dielectric gloves intended for electrical installations above 1000 V can be used in electrical installations up to 1000 V as primary protective equipment. Gloves should be worn to their full depth by pulling the mouth of the bell over the sleeves of the garment. It is unacceptable to wrap the edges of gloves or pull the sleeves of clothes over them.

Gloves made of dielectric rubber, seamless or stitched, with five or two fingers can be used in electrical installations. Only dielectric gloves marked for the protective properties of Ev and En are allowed to be used in electrical installations. The length of the gloves must be at least 350 mm. Dielectric gloves should be sized to allow knitted gloves to be worn underneath to protect the hands from freezing temperatures when working in cold weather. The width along the lower edge of the gloves should allow them to be pulled over the sleeves of the outer garment.

Rules for using dielectric gloves

Before use, the gloves should be inspected, paying attention to the absence of mechanical damage, dirt and moisture, and also check for punctures by turning the gloves towards the fingers.

Each time before use, dielectric gloves should be checked by filling them with air for tightness, i.e. for identification by holes and tears in them, which can cause an electric shock to a person.

When working with gloves, their edges should not be retracted.To protect them from mechanical damage, it is allowed to wear leather or cloth gloves and gloves over gloves.

Used gloves should be periodically washed with soda or soapy water, if necessary, followed by drying.

Dielectric glove testing

During work, electrical tests are carried out on dielectric gloves.

The gloves are immersed in a water bath at a temperature of (25 ± 15) ° C. Water is also poured into the gloves. The water level outside and inside the gloves should be 45-55 mm below their upper edges, which should be dry.

The test voltage is applied between the bath body and the electrode immersed in water inside the glove. It is possible to test several gloves at the same time, but it must be possible to monitor the value of the current flowing through each test glove.

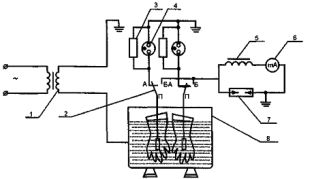

Dielectric gloves are discarded when they break or when the current passing through them exceeds the normalized value. A variant of the test setup is shown in the figure.

Rice. Schematic diagram of testing dielectric gloves, bot and galoshes: 1 — test transformer, 2 — switching contacts, 3 — shunt resistance (15 — 20 kOhm), 4 — gas discharge lamp, 5 — choke, 6 — milliammeter, 7 — limiter , 8 — bath with water

Norms and frequency of electrical tests of gloves are given in «Instructions for use and testing of protective equipment used in electrical installations» (SO 153-34.03603-2003).

At the end of the test, the gloves are dried.

Dielectric galoshes and boots

Dielectric overshoes and boots are used as additional protective equipment in operations performed with basic protective equipment.In this case, bots can be used both in closed and open electrical installations of any voltage, and galoshes — only in closed electrical installations up to and including 1000 V.

In addition, dielectric overshoes and boots are used as surge protection in electrical installations of all voltages and types, including overhead power lines. Dielectric overshoes and boots are worn over regular shoes that must be clean and dry.

Dielectric shoes must be different in color from other rubber shoes. Wellies and boots must consist of a rubber upper, a sole with rubber grooves, a textile lining and internal reinforcements. Shaped bots can be produced without lining. Bots must have cuffs. The height of the bot must be at least 160 mm.

Norms and frequency of electrical tests of dielectric galoshes and bots are given in «Instructions for use and testing of protective equipment used in electrical installations» (SO 153-34.03603-2003).

Rules for using dielectric shoes

Electrical installations must be equipped with dielectric shoes of several sizes. Before use, galoshes and boots must be inspected to detect possible defects (delamination of lining parts or lining, presence of foreign hard inclusions, etc.).

Dielectric carpets

Dielectric carpets are used in rooms with increased danger and especially dangerous in terms of electric shock. At the same time, the premises should not be damp and dusty.

Carpets are spread on the floor in front of equipment, where contact with live parts that are under voltage up to 1000 V is possible, during maintenance and repair of equipment, including in front of shields and assemblies, at rings and brushes of generators and electric motors, on a test wall, etc. .NS. They are also used in places where the switching on and off of knife switches, disconnectors, switches, rheostat control and other operations with switching and starting devices up to 1000 V and higher are carried out.

Dielectric carpets should be at least 75 x 75 cm in size. In damp and dusty rooms, their dielectric properties deteriorate sharply, therefore insulating supports should be used instead of carpets in such rooms.

Dielectric carpets are made in accordance with the requirements of the state standard, depending on the purpose and operating conditions of the following two groups: 1st group — normal performance and 2nd group — oil and gasoline resistant.

Carpets are produced with a thickness of 6 ± 1 mm, length from 500 to 8000 mm and width from 500 to 1200 mm. Carpets must have a ribbed face. Carpets must be of the same color.

An insulating stand is a flooring reinforced on supporting insulators with a height of at least 70 mm. Flooring with a size of at least 500 × 500 mm should be made of well-dried planed wooden boards without knots and inclined layers. The distances between the boards should be 10-30 mm. Boards must be connected without using metal fasteners. Flooring must be painted on all sides. It is allowed to make floor coverings from synthetic materials.

Insulation pads must be strong and stable. In the case of using removable isolators, their connection to the floor covering must exclude the possibility of slipping of the floor covering. To eliminate the possibility of the stand tipping over, the edges of the flooring must not extend beyond the supporting surface of the insulators.

Dielectric carpets and insulating supports are not tested in service. They are examined at least once every 6 months, as well as immediately before use. If mechanical defects are found, the carpets are removed from service and replaced with new ones, and the racks are sent for repair. After repair, the racks must be tested in accordance with the acceptance test standards.

After storage in a warehouse at a negative temperature, dielectric carpets must be stored wrapped at a temperature of (20 ± 5) ° C for at least 24 hours before use.