Advantages and disadvantages of different types of welding

Each type of welding has its advantages and disadvantages compared to others.

Each type of welding has its advantages and disadvantages compared to others.

Gas welding

The advantages of the gas method of welding and cutting include low cost and simplicity of equipment, cheap consumables (hydrogen, propane, methane, ethylene, benzene, gasoline, acetylene), an easy way to regulate combustion, the possibility of any location of the burner in space, high technology, independence from power sources.

The disadvantages of this method are the low efficiency of metal heating, wide seams and a wide zone of thermal effect on welded structures, low productivity, difficulties in automating the process.

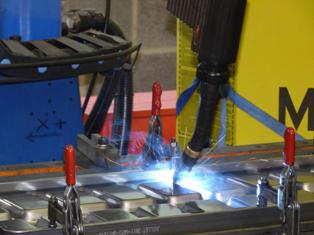

Electric arc welding

Benefits electric arc welding are high manufacturability, wide possibilities for mechanization or automation, smaller heat-affected zone compared to the previous welding method, ease of process control, relatively cheap consumables (welding electrodes), high productivity of the process.

The disadvantages are the need to use special welding converters (rectifiers, inverters) and welding transformers, energy dependence on the electrical network or generators, the need for preliminary preparation of edges (cutting, stripping, fixing parts).

Electroslag welding

The advantages of electroslag welding include: the possibility of welding thick-walled parts, the absence of the need for preliminary preparation of the surfaces to be welded, lower flux consumption compared to arc welding, the possibility of using electrodes of different shapes, improved macrostructure of the weld seam, high productivity, lower energy consumption, small dependence of the gap on the thickness of the metal, the possibility of using this method for remelting steel from waste in order to obtain castings, the possibility of adjusting the process in a wide range of welding currents 0.2 ... 300 A / sq. Mm over the cross-section of the welding electrode, good protection of the welding bath from the influence of air, the possibility of obtaining seams of variable thickness in one pass.

The disadvantages are: welding only in a vertical position (the angle of deviation from the vertical is no more than 30 degrees), the mixing of the metal of the electrodes with the base metal, the coarse-grained structure of the welded metal, the need to use special technological equipment (forming devices, strips, starting pockets, etc.), the impossibility of interrupting the welding before the end of the process, since defects are formed that cannot be removed.

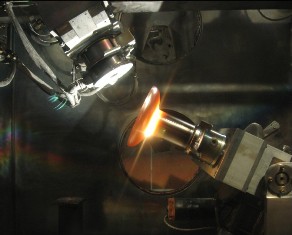

Electron beam welding

The advantages of welding with an electron beam are the following: high efficiency (up to 90%) of the conversion of the kinetic energy of accelerated electrons into thermal energy and high specific power of the beam, high temperature in the welding zone (up to 6000 degrees Celsius). Heat release only in the welding zone, good penetration of deep seams, focusing of the beam reaches values up to 0.001 centimeters, the possibility of using an electron beam for various types of work — drilling, welding, milling of almost any material, a wide range of workpiece thicknesses from 0.02 to 100 mm, high degree of automation.

Disadvantages include the availability of special equipment and highly qualified personnel, the presence of X-rays and the need to protect service personnel and a reduction in the service life of the electronic cathode as a result of its high heating (up to 2400 degrees).

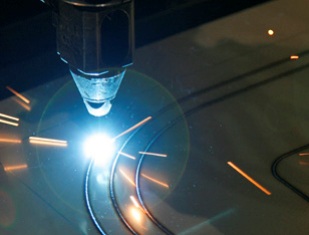

Plasma welding

The advantages of plasma welding are a high degree of heat concentration, good combustion stability, the ability to weld details up to 10 mm thick without preliminary edge preparation, the ability to work at low currents when microplasma welding thin parts (thickness 0.01. ..0.8 mm), the ability to effectively cut almost all types of materials, the ability to carry out the process of spraying or layering when introducing fillers (including refractory) into the plasma arc, the ability to weld metals to non-metals, the minimum area of thermal impact, the ability to work with refractory and heat-resistant metals, reduced consumption of shielding gases compared to the arc method, high adaptability of the process and the possibility of its automation.

Disadvantages of the plasma method include high-frequency noise with ultrasound, optical radiation (infrared, ultraviolet, visible spectrum), harmful ionization of the air, release of metal vapors during the welding process, fragility of the torch nozzle due to strong heating, the need for a special installation and highly qualified service staff.

Laser welding

Advantages of the laser welding method: high concentration of energy, which allows microwelding of details up to 50 microns thick, the possibility of welding heat-sensitive parts, the possibility of welding in hard-to-reach places, the possibility of welding in vacuum and shielding gases, the possibility of supply of strictly dosed energy to the welding zone, high industrial sterility of the process and lack of emissions of harmful vapors, high technology, high degree of automation, high productivity, the possibility of using a laser beam for cutting, layering and drilling.

The disadvantages are the need to purchase an expensive installation, high requirements for personnel qualifications, the presence of vibrations and the need to use vibration-resistant platforms, the need to protect personnel from laser radiation from the equipment.

Thermite welding

On to the benefits thermite welding include simplicity and low cost and disadvantages — high hygroscopicity of the process, danger of fire, explosion, impossibility of process control.

Cold welding

The advantages of the cold welding method are simplicity and the availability of technological equipment, while not requiring high qualification of personnel, the absence of harmful emissions, the possibility of welding without heating, a high degree of mechanization, low energy consumption and high productivity of the process.

The disadvantages include the presence of high specific pressures, a small range of thicknesses of the welded parts, the impossibility of welding high-strength metals.

Explosive welding

Advantages of explosion welding: high welding speed (milliseconds), the possibility of producing bimetallic joints, the possibility of cladding parts (coating with a metal layer with special properties), the possibility of producing curved and straight blanks on a large area, the ability to production of blanks for forging and stamping, the simplicity of the equipment used.

The disadvantages are the need for protection against blasting, the availability of personnel qualification for working with explosives, the impossibility of mechanization and automation.

Friction welding

The advantages of friction welding are high productivity, stable joint quality, the ability to make joints from different metals, the absence of harmful emissions, high energy characteristics, a high degree of mechanization and automation, the ability to use universal turning and drilling machines as the main equipment .

The disadvantages include the need to develop a technological process for each type of metal and configuration of the workpiece, the need to control the welding moment for the timely termination of the welding process, the need to create axial pressure using a special mechanism.