Electric heating methods

Basic methods and methods of converting electrical energy into heat classified as follows. A distinction is made between direct and indirect electric heating.

Basic methods and methods of converting electrical energy into heat classified as follows. A distinction is made between direct and indirect electric heating.

In direct electric heating, the transformation of electrical energy into thermal energy occurs as a result of the passage of electric current directly through the heated body or medium (metal, water, milk, soil, etc.). In indirect electric heating, an electric current passes through a special heating device (heating element), from which the heat is transferred to a heated body or medium by conduction, convection or radiation.

There are several types of conversion of electrical energy into heat, which define methods of electrical heating.

Resistance heating

The flow of electric current through electrically conductive solids or liquid media is accompanied by the evolution of heat. According to the Joule-Lenz law, the amount of heat Q = I2Rt, where Q is the amount of heat, J; I — silatok, A; R is the resistance of a body or medium, Ohm; t — flow time, s.

Resistance heating can be done by contact and electrode methods.

Contact method It is used to heat metals both by the principle of direct electric heating, for example in electric contact welding devices, and by the principle of indirect electric heating — in heating elements.

Electrode method It is used to heat non-metallic conductive materials and media: water, milk, juicy fodder, soil, etc. The heated material or medium is placed between electrodes to which an alternating voltage is applied.

The electric current passing through the material between the electrodes heats it up. Ordinary (non-distilled) water conducts an electric current, because it always contains a certain amount of salts, bases or acids, which dissociate into ions that carry electric charges, that is, an electric current. The character of electrical conductivity of milk and other liquids, soil, succulent fodder, etc. is similar.

Direct electrode heating is performed only on alternating current, since direct current causes electrolysis of the heated material and its deterioration.

Electric resistance heating has found wide application in production due to its simplicity, reliability, flexibility and low cost of heating devices.

Electric arc heating

In an electric arc that occurs between two electrodes in a gaseous medium, electrical energy is converted into heat.

To ignite the arc, the electrodes connected to the power source are briefly touched and then slowly separated. The resistance of the contact at the moment of separation of the electrodes is strongly heated by the current passing through it.Free electrons, constantly moving in the metal, accelerate their movement with increasing temperature at the point of contact of the electrodes.

As the temperature increases, the speed of the free electrons increases so much that they break away from the metal of the electrodes and fly into the air. As they move, they collide with air molecules and separate them into positively and negatively charged ions. The air space between the electrodes is ionized and becomes electrically conductive.

Under the influence of the source voltage, positive ions rush to the negative pole (cathode), and negative ions to the positive pole (anode), thus forming a long discharge - an electric arc accompanied by the release of heat. The temperature of the arc is not the same in its different parts and is at metal electrodes: at the cathode — about 2400 ° C, at the anode — about 2600 ° C, in the center of the arc — about 6000 — 7000 ° C.

Distinguish between direct and indirect electric arc heating. The main practical application is found in direct arc heating in electric arc welding installations. In indirect heating installations, the arc is used as a powerful source of infrared rays.

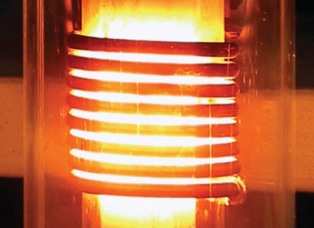

Induction heating

If a piece of metal is placed in an alternating magnetic field, then an alternating e is induced in it. d. s, under the influence of which eddy currents will arise in the metal. The passage of these currents into the metal will cause it to heat up. This method of heating the metal is called induction. The design of some induction heaters is based on the use of the surface effect phenomenon and the proximity effect.

Industrial (50 Hz) and high-frequency (8-10 kHz, 70-500 kHz) currents are used for induction heating. Induction heating of metal bodies (parts, details) is most widespread in machine building and equipment repair, as well as for hardening metal parts. The induction method can also be used to heat water, soil, concrete and pasteurize milk.

Dielectric heating

The physical essence of dielectric heating is as follows. In solid and liquid media with poor electrical conductivity (dielectrics) placed in a rapidly changing electric field, electrical energy is converted into heat.

Every dielectric contains electrical charges bound together by intermolecular forces. These charges are called bound charges, as opposed to free charges in conducting materials. Under the action of an electric field, the associated charges are oriented or displaced in the direction of the field. The displacement of the associated charges under the action of an external electric field is called polarization.

In an alternating electric field, there is a continuous movement of charges and therefore the intermolecular forces of the molecules associated with them. The energy expended by the source to polarize the molecules of non-conducting materials is released in the form of heat. Some non-conducting materials have a small amount of free charges that, under the influence of an electric field, create a small conduction current that contributes to the release of additional heat in the material.

When heating with a dielectric, the material to be heated is placed between metal electrodes — capacitor plates, to which high-frequency voltage (0.5 — 20 MHz and higher) from a special high-frequency generator. The dielectric heating body consists of a high-frequency lamp generator, a power transformer and a drying device with electrodes.

High-frequency dielectric heating is a promising heating method and is mainly used for drying and heat treatment of wood, paper, food and feed (drying grain, vegetables and fruits), pasteurization and sterilization of milk, etc.

Electron beam heating (electronic)

When a stream of electrons (electron beam) accelerated in an electric field encounters a heated body, the electrical energy is converted into heat. A characteristic feature of electronic heating is a high energy concentration density of 5×108 kW / cm2, which is several thousand times higher than in electric arc heating. Electronic heating is used in industry for welding very small parts and melting ultrapure metals.

In addition to the considered methods of electric heating, infrared heating (irradiation) is used in production and everyday life.