Spraying methods

Spraying — the technological process of forming coatings by spraying liquid dispersed particles that are deposited on impact upon impact with the surface. The cooling rate of the particles is 10,000-100,000,000 degrees per second, which results in very fast crystallization of the sprayed coating and low surface heating temperature.

Spraying — the technological process of forming coatings by spraying liquid dispersed particles that are deposited on impact upon impact with the surface. The cooling rate of the particles is 10,000-100,000,000 degrees per second, which results in very fast crystallization of the sprayed coating and low surface heating temperature.

Coatings are sprayed to increase corrosion resistance, wear resistance, heat resistance and repair of worn assemblies and parts.

There are several ways to spray coatings:

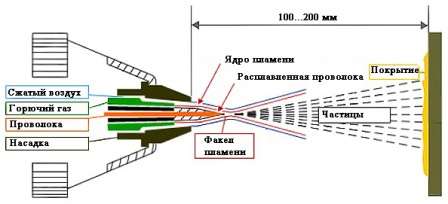

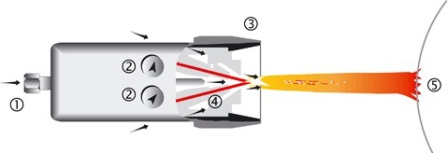

1) Flame spraying with wire, powder or stick (Fig. 1, 2). The dispersed material is melted in the flame of a gas burner by burning a combustible gas (usually a mixture of acetylene-oxygen in a ratio of 1: 1) and is carried to the surface by a jet of compressed air. The melting temperature of the sprayed material must be lower than the flame temperature of the combustible mixture (table 1).

The advantages of this method are the low cost of equipment and its operation.

Rice. 1. Flame wire spraying

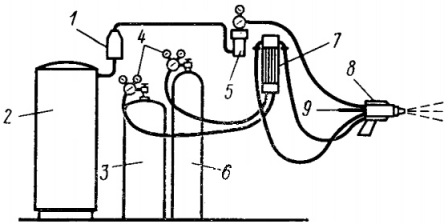

Rice. 2.Schematic of postal wire spraying equipment: 1 — air dryer, 2 — compressed air receiver, 3 — fuel gas cylinder, 4 — reducers, 5 — filter, 6 — oxygen cylinder, 7 — rotameters, 8 — spray torch , 9 — wire feeding channel

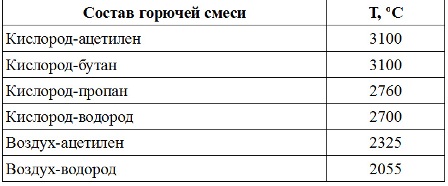

Table 1. Flame temperature of combustible mixtures

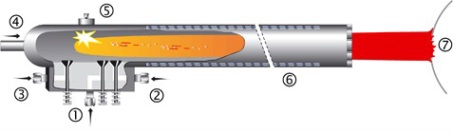

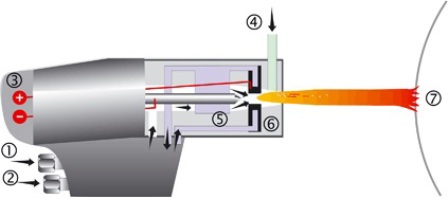

2) Detonation spraying (Figure 3) is carried out several cycles per second, for each cycle the thickness of the sprayed layer is about 6 microns. Dispersed particles have a high temperature (over 4000 degrees) and speed (over 800 m / s). In this case, the temperature of the base metal is low, which excludes its thermal deformation. However, deformation can occur from the action of a detonation wave and this is a limitation of the application of this method. The cost of detonation equipment is also high; a special camera is required.

Rice. 3. Spraying with detonation: 1 — acetylene supply, 2 — oxygen, 3 — nitrogen, 4 — sprayed powder, 5 — detonator, 6 — water cooling pipe, 7 — detail.

3) Arc metallization (Figure 4). Two wires are fed into the wire of the electrometalizer, one of which serves as the anode and the other as the cathode. An electric arc occurs between them and the wire melts. Spraying is done using compressed air. The process takes place with direct current. This method has the following advantages:

a) high productivity (up to 40 kg / h sprayed metal),

b) more durable coatings with high adhesion compared to the flame method,

c) the possibility of using wires of different metals makes it possible to obtain a "pseudo-alloy" coating,

d) low operating costs.

The disadvantages of metal arc metallization are:

a) the possibility of overheating and oxidation of the sprayed materials at a low feed rate,

b) combustion of alloying elements of the sprayed materials.

Rice. 4. Electric arc metallization: 1 — compressed air supply, 2 — wire feed, 3 — nozzle, 4 — conductive wires, 5 — detail.

4) Plasma spraying (Figure 5). In plasmatrons, the anode is a water-cooled nozzle and the cathode is a tungsten rod. Argon and nitrogen are commonly used as plasma forming gases, sometimes with the addition of hydrogen. The temperature at the outlet of the nozzle can be several tens of thousands of degrees; as a result of the sharp expansion of the gas, the plasma jet acquires a high kinetic energy.

The high temperature plasma spraying process allows the application of refractory coatings. Changing the spray pattern makes it possible to use a wide variety of materials, from metal to organics. The density and adhesion of such coatings are also high. The disadvantages of this method are: relatively low productivity and intense ultraviolet radiation.

Read more about this coating method here: Plasma Spray Coatings

Rice. 5. Plasma spraying: 1 — inert gas, 2 — cooling water, 3 — direct current, 4 — sprayed material, 5 — cathode, 6 — anode, 7 — part.

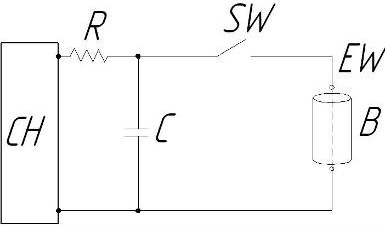

5) Electropulse spraying (Figure 6). The method is based on the explosive melting of a wire when an electrical discharge of a capacitor passes through it. In this case, about 60% of the wire melts, and the remaining 40% goes into a gaseous state. The melt consists of very small particles from a few hundredths to a few millimeters.If the discharge level is excessive, the metal in the wire completely turns into a gas. The movement of particles towards the sprayed surface is due to the expansion of the gas during the explosion.

The advantages of the method are the absence of oxidation as a result of air displacement, high density and adhesion of the coating. Disadvantages include the limitation in the choice of materials (they must be electrically conductive), as well as the impossibility of obtaining thick coatings.

Rice. 6. Schematic of electric pulse spraying: CH — power supply for the capacitor, C — capacitor, R — resistor, SW — switch, EW — wire, B — detail.

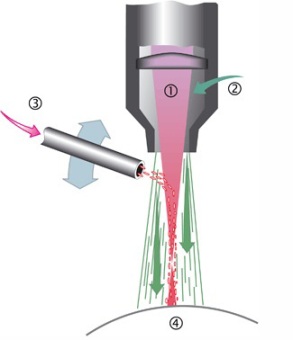

6) Laser spraying (Figure 7). In laser spraying, the powder is fed onto the laser beam through a feed nozzle. In a laser beam, the powder is melted and applied to the workpiece. The shielding gas serves as protection against oxidation. The field of application of laser spraying is the coating of tools for stamping, bending and cutting.

Powder materials are used for flame, plasma, laser and detonation spraying. Wire or stick — for gas-flame, electric arc and electric pulse spraying. The finer the powder fraction, the smaller the porosity, the better the adhesion and the higher the quality of the coating. The sprayed surface for each spraying method is located at a distance of at least 100 mm from the nozzle.

Rice. 7. Laser spraying: 1 — laser beam, 2 — protective gas, 3 — powder, 4 — detail.

Sprayed parts

Spraying of coatings is applied:

-

general mechanical engineering for strengthening parts (bearings, rollers, gears, gauges, including threaded ones, machine centers, dies and punches, etc.);

-

in the automotive industry for the coating of crankshafts and camshafts, brake knuckles, cylinders, piston heads and rings, clutch discs, exhaust valves;

-

in the aviation industry for covering nozzles and other elements of engines, turbine blades, for lining the fuselage;

-

in the electrotechnical industry — for coatings of capacitors, antenna reflectors;

-

in the chemical and petrochemical industry — for covering valves and valve seats, nozzles, pistons, shafts, impellers, pump cylinders, combustion chambers, for corrosion protection of metal structures operating in the marine environment;

-

in medicine — for spraying electrodes of ozonators, prostheses;

- in everyday life — to strengthen kitchen equipment (dishes, stoves).