Laser welding

In the laser welding method, a concentrated light beam with a high energy density (beam diameter 0.1 ... 2 mm) is used to connect parts. According to the type of light beam, laser welding can be pulsed and continuous. Spot joints are welded in a pulsed manner, for continuous seams pulsed-periodic or continuous radiation is used. Pulse welding is also used when it is necessary to ensure minimal deformations from temperature heating and high accuracy, continuously — for high-speed welding in serial or mass production.

In the laser welding method, a concentrated light beam with a high energy density (beam diameter 0.1 ... 2 mm) is used to connect parts. According to the type of light beam, laser welding can be pulsed and continuous. Spot joints are welded in a pulsed manner, for continuous seams pulsed-periodic or continuous radiation is used. Pulse welding is also used when it is necessary to ensure minimal deformations from temperature heating and high accuracy, continuously — for high-speed welding in serial or mass production.

Laser welding is used to join various materials: steel, titanium, aluminum, refractory metals, copper, metal alloys, precious metals, bimetals, with a thickness of tens to several millimeters. However, laser welding reflective metals such as aluminum and copper is somewhat difficult. Laser welding of metals is shown in fig. 2.

The welding of active metals is carried out using shielding gas in the form of a jet directed in the area of exposure to the light beam.

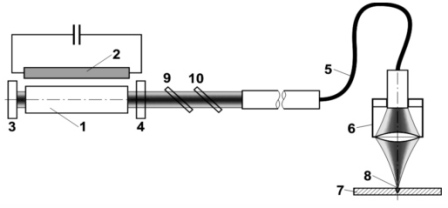

Photo 1 — Welding in solid state laser: 1 — active medium (ruby, garnet, neodymium), 2 — pump lamp, 3 — opaque mirror, 4 — translucent mirror, 5 — optical fiber, 6 — optical system, 7 — detail, 8 — laser beam at the focus point, 9, 10 — laser beam splitters.

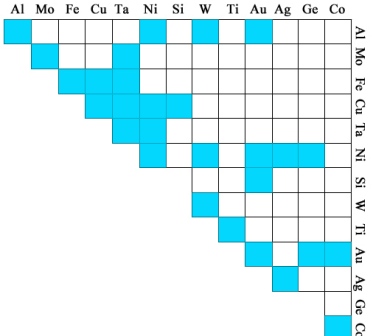

Photo 2 — Weldability of materials

According to the depth of penetration, there are three types of laser welding:

1) microwelding (less than 100 microns),

2) mini-welding (0.1 ... 1 mm),

3) macro welding (more than 1 mm).

Since the penetration depth usually does not exceed 4 mm, laser welding is widely used mainly in precision tool manufacturing, in the manufacture of electronic devices, watches, in aircraft construction, in the automotive industry, in pipe welding, and is also used widely in the jewelry industry.

Before butt welding and overlapping, ensure a gap of 0.1 ... 0.2 mm. With large gaps, burnout and lack of synthesis may occur.

The main parameters of the laser welding mode are:

1) pulse duration and energy,

2) pulse frequency,

3) the diameter of the light beam,

4) the distance from the smallest part of the focused beam to the surface,

5) welding speed. It reaches 5 mm / s. To increase the speed, the pulse frequency is increased or continuous mode is used.

Industry uses 2 types of lasers for laser welding:

1) solid-state - ruby, neodymium and YAG lasers (based on yttrium aluminum garnet);

2) gas CO2 lasers.

Recently, laser welding machines have also appeared, the active element of which is an optical fiber made of quartz.Such lasers allow welding of "problematic" materials — copper and brass with high reflectivity, titanium.

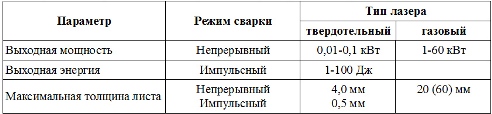

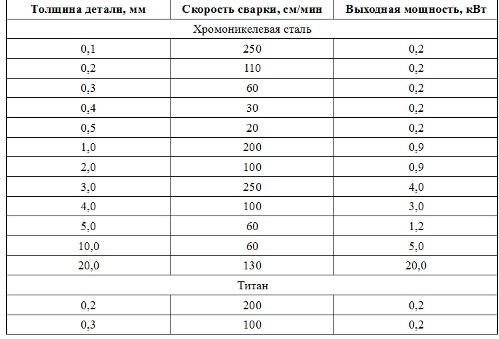

The capabilities of various laser welding machines are shown in Tables 1 and 2.

Examples of CO2 gas laser welding modes are shown in Table 3.

Table 1 — Sheet thickness and welding laser power

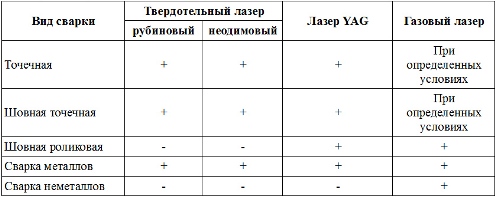

Table 2 — Applicability of lasers

Table 3 — Modes of laser butt welding with a gas laser

The diameter of the laser beam is usually 0.3 mm. Butt welds welded with a beam smaller than 0.3 mm may have lack of adhesion and lack of penetration. Welding with lasers up to 10 kW is usually done without filler.

Due to the small area affected by heat during laser welding, the weld cools very quickly. This can have both negative and positive consequences for the quality of the welded joint. Many metals give the best physical and mechanical properties with rapid cooling of the joints. However, when welding stainless steel, this can lead to weld fracture. Increasing the pulse width to 10 ms and preheating helps to eliminate this phenomenon.

With the right choice of welding materials and modes, laser welding produces seams of the highest quality.

Laser systems can be divided into 3 categories:

1) Enclosure devices. In such devices, the workpieces are placed in a special closed space containing a protective neutral atmosphere and a laser beam. The welder can control and monitor the welding process using a special optical system.

2) Devices intended for outdoor welding.The laser beam has several degrees of freedom and produces programmed movements. The welding zone is protected by a gas flow.

3) Devices intended for manual laser welding. Laser torches are very similar to TIG welding torches. The laser beam is transmitted to the torch using an optical fiber. During welding, the welder holds the laser torch in one hand and the filler material in the other.

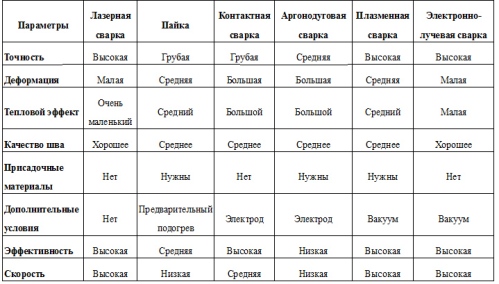

Table 4 — Comparison of different types of laser welding

Advantages of laser welding include:

1) a small area of thermal effect of the laser beam on the material and, as a result, insignificant thermal deformations;

2) the possibility of welding in hard-to-reach places, in an environment transparent to laser radiation (glass, liquids, gases);

3) welding of magnetic materials;

4) small diameter of the light beam, possibility of micro welding, narrow welding seam with good aesthetic characteristics;

5) the ability to automate the process;

6) flexible manipulation of the light beam through optical transmission;

7) the versatility of laser equipment (the possibility of use for laser welding and cutting, marking and drilling);

8) the possibility of welding different materials.

Disadvantages of laser welding:

1. High cost and complexity of laser equipment.

2. High requirements for preparation, cleaning of welding edges.

3. Impossibility of welding thick-walled parts, insufficient power.Increasing the power of welding lasers is limited by the fact that with a stronger effect of the laser beam on the metal, it is actively scattered in the welding zone, which damages the optical system of the device and deactivates the laser in a matter of hours.