Ultrasonic welding

Ultrasonic welding uses high-frequency ultrasonic acoustic vibrations that are applied to joined parts that are assembled together under low pressure. This welding method is most often used to join thermoplastics and when bolting, soldering or gluing is not suitable.

Ultrasonic welding uses high-frequency ultrasonic acoustic vibrations that are applied to joined parts that are assembled together under low pressure. This welding method is most often used to join thermoplastics and when bolting, soldering or gluing is not suitable.

Although ultrasonic welding was developed as early as the 1940s, it was first used industrially in the early 1960s to weld fine wires in the electronics industry. In 1963, ultrasonic welding began to be used to bond polyethylene. Since then, ultrasonic welding has been used to weld aluminum and thin sheet metal in the automotive industry (ignition modules, terminal wires, wires).

The slow process of recognizing the advantages of ultrasonic welding in industry is due to the lack of powerful ultrasonic equipment that can guarantee consistent welding quality even for large parts.As a result, research in the 1980s and 1990s was mainly focused on the development of ultrasound equipment.

Although ultrasonic welding uses vibrations, this method is different from "vibration welding", also known as friction welding. In the case of vibration welding, one of the parts to be joined is held in place and the other is oscillating (by an electromagnetic or hydraulic drive).

Ultrasonic welding holds the two parts in place and uses high-frequency sound waves to create friction. The acoustic energy creates friction and produces heat that results in parts being welded in less than a second, making ultrasonic welding one of the fastest in use today.

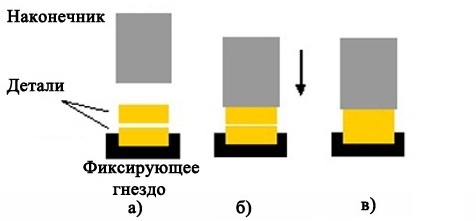

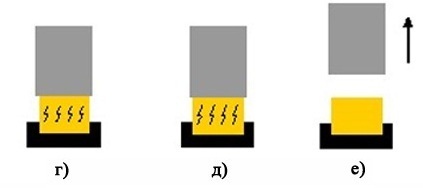

The process of ultrasonic welding is fully automated and is carried out on special installations. The principle of ultrasonic welding is shown in fig. 1, and the composition of a typical installation is shown in fig. 2.

Rice. 1. Principle of ultrasonic welding: a — alignment of parts, b — contact of parts with the tip, c — application of pressure, d — welding, e — holding, f — lifting of the tip

Rice. 2. Assembly diagram for sonic welding

The generator (in a separate unit) is used to convert electrical vibrations from the network into high-frequency (20 ... 60 kHz), the transducer, using piezoelectric elements, converts electrical vibrations into acoustic ones. The amplifier and sonotrode are passive resonant elements of the installation that serve to transfer vibrations from the transducer to the parts.

Typically, ultrasonic welding machines are equipped with a set of amplifiers with different displacement transformation ratios.The shape of the sonotrode is determined by the required weld configuration. Longitudinal radial, edge and other wave oscillations are created depending on the shape of the sonotrode. Each seam requires its own sonotrode.

The physical essence of the process consists in the appearance of very strong vibrations of small amplitude at the contact of two parts. Vibration combined with pressure removes impurities and oxides from the surface of the parts. Electrons begin to flow between the parts, forming a metallurgical seam.

Ultrasonic welding is ideal for making electrical connections, welding aluminum and copper, sealing the ends of copper pipes, welding plastics, embedding metal parts in plastics.

Rice. 3. Joints made by ultrasonic welding

Ultrasonic welding of plastics allows for more reliable joints than other methods. In this case, ultrasonic welding of plastics is fundamentally different from welding metals.

First, ultrasonic welding of metals occurs by means of transverse vibrations parallel to the welded surfaces. Ultrasonic welding of plastics uses longitudinal vibrations that are normal (ie at right angles) to the surfaces being welded. The shape of the sonotrodes, which transmit ultrasonic vibrations to metal and plastic seams, are also completely different.

Second, when welding metals, a seam is created by the frictional interaction of the surfaces, which creates a rigid connection without melting the material.Ultrasonic welding of plastic parts is based on melting the material in the same way as many other traditional welding methods, such as arc welding, resistance or laser welding), but in much lower temperature ranges.

Rice. 4. Ultrasonic welding equipment

The advantages of ultrasonic welding:

1. No special surface cleaning required.

2. No protective atmosphere required.

3. No welding consumables (wire, electrodes, solder, etc.) are required.

4. Low power consumption.

5. Short splicing time to form a joint (about a quarter of a second).

6. Full automation of the welding process and the possibility of easy integration with other production processes.

7. Possibility of welding materials of different nature, including those sensitive to high temperatures, since a small amount of heat is generated during welding.

8. Welding all kinds of details.

9. The welds created by this process are visually pleasing, neat.

10. Ultrasonic welding does not use corrosive chemicals and produces a small amount of fumes, unlike other methods.

Limitations of ultrasonic welding:

1. The most serious limitation in the use of ultrasonic welding is the size of the welded parts — no more than 250 mm. This is due to the limitations in the output power of the transducer, the inability of the sonotrode to transmit very high power ultrasound waves, and the difficulty in controlling the amplitude.

2. Ultrasonic welding also requires a lower moisture content in the materials being joined.Otherwise, vibration welding is preferred.

3. Ultrasonic welding is not effective for joining thick-walled materials. At least one of the parts to be connected must be light, as it «absorbs» a huge amount of energy.