Induction hardening — application, physical process, types and methods of hardening

This article will focus on induction hardening — one of the types of heat treatment of metals that provides the possibility of phase transformations, that is, the transformation of pearlite into austenite. Steel parts, due to induction hardening, acquire higher mechanical properties, since the quality of the steel increases significantly as a result of such treatment.

So, for heat treatment of metals, with the purpose of their surface hardening, they use induction heating... The technology allows you to choose different depths of the hardened layer, in addition, the process is easily automated, which is why this method is considered progressive. It is possible to solidify parts with different shapes.

Surface induction hardening is of two types: surface and bulk-surface.

Surface hardening with surface heating, this results in the workpiece being heated to the hardening temperature to the depth of the hardened layer, while the core remains intact. The heating time is from 1.5 to 20 seconds, the heating speed is from 30 to 300 ° C per second.

Volume hardening of the surface is characterized by heating of a layer larger than a layer with a martensitic structure, this is deep heating. The steel is annealed to a depth less than the thickness of the heated layer, which is determined by the hardening of the steel.

In deep zones deeper than the martensitic structure, which are heated to the solidification temperature, solidified zones with the structure of solidified sorbitol or troostite are formed. The curing time increases to 20-100 seconds, the heating rate decreases to 2-10 ° C per second compared to surface curing.

Heavy-duty axles, gears, crosses, etc. are subjected to volumetric surface hardening. The main difference between induction heating and other heating methods is the release of heat directly into the volume of the workpiece.

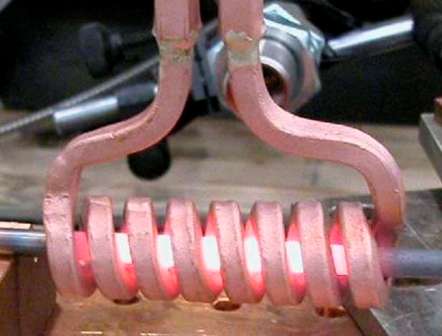

Basically the process is as follows. The hardened part is placed in the inductor, which is powered by alternating current. A variable magnetic field induces an EMF eddy currents occur in the surface layer of the workpiece, heating the workpiece. These areas, which are affected by an alternating magnetic field, are heated to high temperatures.

The heating speed is high and there is an option for local heating. The current density is higher on the surface of the workpiece due to the surface effect, which is why heating is possible only to the required depth. The core heats up slightly.87% of the power transmitted by the eddy currents of the workpiece is in the penetration depth.

Since the depth of current penetration is different at different temperatures of the metal, the process takes place in several stages. First of all, the surface layer of the cold metal is quickly heated, then the layer is heated deeper and the first layer is not heated so quickly further, then the third layer is heated.

In the process of heating each of the layers, the heating rate of each layer decreases with the corresponding layer's loss of magnetic properties. That is, heat spreads due to changes in the magnetic properties of the metal from layer to layer. This is active heating by current, it lasts literally seconds.

Induction heating, depending on the temperature distribution in the section of the workpiece, differs from heating by thermal conduction. In the heated layer, the temperature is significantly higher than in the center, there is a sharp drop, because in the central part of the part, the magnetic properties are still are not lost until the outside active current has already overheated the metal. By changing the frequency of the current and the duration of heating, the workpiece is heated to the required depth.

The design of the inductor usually determines the solidification quality of the part. The inductor is made of copper tubes through which water is passed to cool it. A certain distance, measured in units of millimeters, is maintained between the inductor and the part, and the same on all sides.

Quenching is done in a variety of ways, depending on the shape and size of the part, as well as the quenching requirements. Small parts are first heated and then cooled.In shower cooling, a cooling medium such as water is fed through holes in the inductor. If the part is long, the inductor moves along it during quenching and the water is fed through the shower holes after its movement. It is a continuous sequential curing method.

In continuous sequential curing, the inductor moves at a speed of 3 to 30 mm per second and portions of the part fall successively into its magnetic field. As a result, the part is successively, section by section, heated and cooled. In this way, individual parts of the workpiece can also be hardened if necessary, for example crankshaft journals or the teeth of a large gear wheel. Automation tools allow you to align the part evenly and move the inductor with high precision.

Depending on the brand of steel and the method of its pretreatment, the properties after hardening are different. Induction heating, cooling and low tempering modes also affect the results.

Unlike conventional hardening, induction hardening makes the steel 1-2 HRC harder, stronger, reduces less toughness and increases the endurance limit. This is due to the grinding of the austenite grains.

A high heating rate leads to an increase in pearlite-austenite transformation centers. The initial austenite grain turns out to be small, growth does not occur due to the high heating rate and lack of exposure.

Martensite crystals are smaller. The austenite grain is 12-15 points. When using steels with little tendency to grow austenitic grains, a fine grain is obtained.Parts with a slightly scattered initial structure are obtained as a result of better quality.

As a result of the distribution of residual stresses, the endurance limit increases. Residual compressive stresses are present in the hardened layer, while tensile stresses are present outside it. Fatigue failures are related to tensile stresses. Compressive stresses will weaken the destructive tensile forces under the action of external forces during the operation of the part. This is why the endurance limit increases as a result of induction hardening.

The decisive importance in induction hardening are: heating rate, cooling rate, mode of hardening at low temperatures.