Physical basis of methods for high-frequency heating of dielectrics (dielectric drying)

In industrial technological processes, it is often necessary to heat materials belonging to the group of dielectrics and semiconductors. Typical representatives of such materials are various types of rubber, wood, fabrics, plastics, paper, etc.

For electric heating of such materials, installations are used that use the ability of dielectrics and semiconductors to seize when exposed to an alternating electric field.

Heating occurs because in this case part of the energy of the electric field is irretrievably lost, turning into heat (dielectric heating).

From a physical point of view, this phenomenon is explained by the consumption of displacement energy electrical charges in atoms and molecules, which is caused by the action of an alternating electric field.

Due to the simultaneous heating of the entire volume of the product dielectric heating especially recommended for applications requiring even and gentle drying.This solution is best suited for drying heat-sensitive products in the food, industrial and medical industries to preserve all their properties.

It is important to note that the effect of an electric field on a dielectric or semiconductor occurs even in the absence of direct electrical contact between the electrodes and the material. It is only necessary that the material be in the area of the electric field acting between the electrodes.

The use of high-frequency electric fields to heat dielectrics was proposed in the 1930s. For example, US Patent 2,147,689 (filed to Bell Telephone Laboratories in 1937) states: "The present invention relates to a heating device for dielectrics, and the object of the present invention is to heat such materials uniformly and substantially simultaneously."

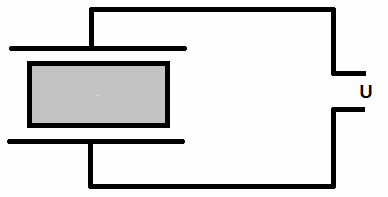

The simplest diagram of a device for heating with a dielectric in the form of two flat electrodes to which an alternating voltage is applied and a heated material placed between the electrodes is shown in the figure.

Dielectric heating circuit

The diagram shown is electric capacitor, in which the heated material acts as an insulator between the plates.

The amount of energy absorbed by the active power component material is determined and is found in the following ratio:

P = USe·I becausephi = USe2·w C tg delta,

where UTo — voltage on the plates of the capacitor; C is the capacitance of the capacitor; tg delta — dielectric loss angle.

Injection delta (angle of dielectric losses) complementary angle fi up to 90 ° (fi is the displacement angle between the active and reactive power components) and since in all dielectric heating devices the angle is close to 90 °, we can assume that the cosine phi approximately equal to tangent delta.

For an ideal lossless capacitor, the angle fi= 90 °, i.e. the current and voltage vectors are mutually perpendicular and the circuit has a purely reactive power.

The presence of a dielectric loss angle other than zero is an undesirable phenomenon for conventional capacitors because it causes energy losses.

In dielectric heating installations, it is precisely these losses that represent a useful effect. The operation of such installations with a loss angle delta = 0 is not possible.

For flat parallel electrodes (flat capacitor), the power per unit volume of the material between the electrodes can be calculated by the formula

Py = 0.555·e daTgdelta,

where f is the frequency, MHz; Ru — specific absorbed power, W / cm3, e — electric field strength, kv / cm; da = e / do is the relative dielectric constant of the material.

This is YThe comparison shows that the efficiency of dielectric heating is determined by:

-

parameters of the electric field generated by the installation (e and f);

-

electrical properties of materials (dielectric loss tangent and relative dielectric constant of the material).

As the analysis of the formula shows, the efficiency of the installation increases with increasing strength and frequency of the electric field. In practice, this is possible only within certain limits.

At a frequency higher than 4-5 MHz, the electrical efficiency of the high-frequency generator-converter decreases sharply, so the use of higher frequencies turns out to be economically unprofitable.

The highest value of the electric field strength is determined by the so-called breakdown field strength for each specific type of processed material.

When the strength of the breakdown field is reached, there is either a local violation of the integrity of the material, or the occurrence of an electric arc between the electrodes and the surface of the material. In this regard, the strength of the working field must always be less than that of the breakdown.

The electrical properties of the material depend not only on its physical nature, but also on the variable parameters characterizing its state — temperature, humidity, pressure, etc.

These parameters change during the technological process, which must be taken into account when calculating dielectric heating devices. Only with the correct consideration of all these factors in their interaction and change, the economically and technologically advantageous use of dielectric heating devices in industry can be ensured.

A high-frequency glue press is a device that uses dielectric heating, for example, to speed up the gluing of wood. The device itself is pretty much a regular glue press. However, it also has special electrodes for creating a high-frequency electric field in the part to be glued. The field quickly (within a few tens of seconds) raises the temperature of the product, usually up to 50 — 70 ° C. This significantly accelerates the drying of the glue.

Unlike high-frequency heating, microwave heating is dielectric heating with a frequency above 100 MHz, and electromagnetic waves can be emitted from a small emitter and directed at an object through space.

Modern microwave ovens use electromagnetic waves at much higher frequencies than high frequency heaters. Typical home microwaves operate in the 2.45 GHz range, but there are also 915 MHz microwaves. This means that the wavelength of the radio waves used in microwave heating is from 0.1 cm to 10 cm.

The generation of microwave oscillations in microwave ovens takes place with magnetrons.

Each dielectric heating installation consists of a frequency converter generator and an electrothermal device — a capacitor with specially shaped plates. Because dielectric heating requires a high frequency (from hundreds of kilohertz to units of megahertz).

The most important task of the technology for heating dielectric materials with high-frequency currents is to ensure the necessary mode during the entire processing process. The solution to this problem is complicated by the fact that the electrical properties of materials change during heating, drying or in result of other changes in the state of the material. The consequence of this is a violation of the thermal regime of the process and a change in the mode of operation of the lamp generator.

Both factors play a significant role. Therefore, when developing a technology for heating dielectric materials with high-frequency currents, the properties of the processed material must be carefully studied and the change in these properties must be analyzed throughout the technological cycle.

The dielectric constant of a material depends on its physical properties, temperature, humidity and electric field parameters. The dielectric constant usually decreases as the material dries and in some cases can change tens of times.

For most materials, the frequency dependence of the dielectric constant is less pronounced and should be taken into account only in some cases. For skin, for example, this dependence is significant in the low-frequency region, but as the frequency increases, it becomes insignificant.

As already mentioned, the dielectric constant of materials depends on the temperature change that always accompanies drying and heating processes.

The tangent of the angle of dielectric losses also does not remain constant during processing, and this has a significant impact on the course of the technological process, since the delta tangent characterizes the ability of the material to absorb the energy of an alternating electric field.

To a large extent, the tangent of the dielectric loss angle depends on the moisture content of the material. For some materials, the tangent delta changes by several hundred times from its initial value by the end of the machining process. So, for example, for yarn, when the humidity changes from 70 to 8%, the tangent of the absorption angle decreases 200 times.

An important characteristic of the material is breakdown electric field stress permitted by this material.

The increase in the breakdown strength of the electric field limits the possibility of increasing the voltage on the capacitor plates and thus determines the upper limit of the power that can be installed.

An increase in the temperature and humidity of the material, as well as the frequency of the electric field, leads to a decrease in the strength of the breakdown field.

In order to ensure a predetermined technological mode even with changes in the electrical parameters of the material during the drying process, it is necessary to adjust the operating mode of the generator. With the correct change in the operating mode of the generator, it is possible to achieve optimal conditions during the entire operating cycle and achieve high efficiency of the installation.

The design of the working condenser is determined by the shape and size of the heated parts, the properties of the heated material, the nature of the technological process and, finally, the type of production.

In the simplest case, it consists of two or more flat plates parallel to each other. Plates can be horizontal and vertical. Flat electrodes are used in installations for drying sawn timber, sleepers, yarns, gluing plywood.

The uniformity of the heating materials depends on the uniformity of the distribution of the electric field throughout the entire volume of the treated object.

The presence of inhomogeneity in the structure of the material, a variable air gap between the electrode and the outer surface of the part, the presence of conductive masses (holders, supports, etc.) near the electrodes lead to an uneven distribution of the electric field.

Therefore, in practice, a wide variety of design options for working capacitors are used, each of which is designed for a certain technological process.

Installations for heating with a dielectric in a high-frequency electric field have a relatively low efficiency at a rather high cost of the equipment included in these installations. Therefore, the use of such a method can be justified only after a thorough study and comparison of the economic and technological indicators of different heating methods.

A frequency converter is required for all high frequency dielectric heating systems. The overall efficiency of such converters is defined as the ratio of the power supplied to the capacitor plates to the power received from the power grid.

Values of the coefficient of useful action are in the range of 0.4 - 0.8. The amount of efficiency depends on the load on the frequency converter. As a rule, the highest efficiency of the converter is achieved when it is normally loaded.

The technical and economic indicators of dielectric heating installations significantly depend on the design of the electrothermal device. Properly selected design of the latter ensures high efficiency and machine time factor.

See also:

Dielectrics in an electric field