Electrophysical methods for processing metals

The widespread use of difficult-to-machine materials for the production of machine parts, the complexity of the design of these parts, combined with the growing requirements to reduce costs and increase productivity, led to the development and adoption of electrophysical machining methods.

The widespread use of difficult-to-machine materials for the production of machine parts, the complexity of the design of these parts, combined with the growing requirements to reduce costs and increase productivity, led to the development and adoption of electrophysical machining methods.

Electrophysical methods of metal processing are based on the use of specific phenomena arising from the action of electric current to remove material or change the shape of the part.

The main advantage of electrophysical methods of metal processing is the ability to use them to change the shape of parts made of materials that cannot be processed by cutting, and these methods are processed under conditions of minimal forces or in their complete absence.

An important advantage of electrophysical methods for processing metals is the independence of the productivity of most of them from the hardness and brittleness of the processed material.The labor intensity and duration of these methods for processing materials with increased hardness (HB> 400) are less than the labor intensity and duration of cutting.

Electrophysical methods of metal processing cover almost all machining operations and are not inferior to most of them in terms of achieved roughness and accuracy of processing.

Electric discharge treatment of metals

Electric discharge processing is a type of electrophysical processing and is characterized by the fact that changes in the shape, size and surface quality of the part occur under the influence of electric discharges.

Electrical discharges occur when a pulsed electric current passes through a gap of 0.01 - 0.05 mm wide between the workpiece electrode and the tool electrode. Under the influence of electrical discharges, the workpiece material melts, vaporizes and is removed from the interelectrode gap in a liquid or vapor state. Similar processes of destruction of electrodes (details) are called electrical erosion.

Electrical discharges occur when a pulsed electric current passes through a gap of 0.01 - 0.05 mm wide between the workpiece electrode and the tool electrode. Under the influence of electrical discharges, the workpiece material melts, vaporizes and is removed from the interelectrode gap in a liquid or vapor state. Similar processes of destruction of electrodes (details) are called electrical erosion.

To enhance electrical erosion, the gap between the workpiece and the electrode is filled with a dielectric liquid (kerosene, mineral oil, distilled water). When the electrode voltage is equal to the breakdown voltage, a conductive channel is formed in the middle between the electrode and the workpiece in the form of a plasma-filled cylindrical region with a small cross-section with a current density of 8000-10000 A / mm2. The high current density, maintained for 10-5 — 10-8 s, ensures a temperature of the workpiece surface up to 10,000 — 12,000˚C.

The metal removed from the surface of the workpiece is cooled with a dielectric liquid and solidifies in the form of spherical granules with a diameter of 0.01 — 0.005 mm.At each subsequent moment in time, a current pulse pierces the interelectrode gap at the point where the gap between the electrodes is the smallest. The continuous supply of current pulses and the automatic approach of the tool electrode to the workpiece electrode ensure continuous erosion until a predetermined workpiece size is reached or all the workpiece metal in the interelectrode gap is removed.

The metal removed from the surface of the workpiece is cooled with a dielectric liquid and solidifies in the form of spherical granules with a diameter of 0.01 — 0.005 mm.At each subsequent moment in time, a current pulse pierces the interelectrode gap at the point where the gap between the electrodes is the smallest. The continuous supply of current pulses and the automatic approach of the tool electrode to the workpiece electrode ensure continuous erosion until a predetermined workpiece size is reached or all the workpiece metal in the interelectrode gap is removed.

Electric discharge processing modes are divided into electric spark and electric pulse.

Modes of electrospar characterized by the use of spark discharges of short duration (10-5 ... 10-7s) with straight polarity of connecting the electrodes (detail "+", tool "-").

Depending on the strength of the spark discharges, the modes are divided into hard and medium (for preliminary processing), soft and extremely soft (for final processing). The use of soft modes provides a deviation of the dimensions of the part up to 0.002 mm with a roughness parameter of the processed surface Ra = 0.01 μm. The modes of electric sparks are used in the processing of hard alloys, hard-to-machine metals and alloys, tantalum, molybdenum, tungsten, etc. They process through and deep holes of any cross-section, holes with curved axes; using wire and tape electrodes, cut parts from sheet blanks; chipped teeth and threads; parts are polished and branded.

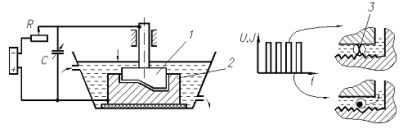

To carry out processing in electrospark modes, machines are used (see fig.), equipped with RC generators, consisting of a charged and discharged circuit.The charging circuit includes a capacitor C, which is charged through a resistance R from a current source with a voltage of 100-200 V, and electrodes 1 (tool) and 2 (part) are connected to the discharge circuit in parallel with the capacitor C.

As soon as the voltage on the electrodes reaches the breakdown voltage, a spark discharge of energy accumulated in the capacitor C occurs through the interelectrode gap. The efficiency of the erosion process can be increased by reducing the resistance R. The constancy of the interelectrode gap is maintained by a special tracking system , which controls the mechanism for the automatic feed movement of a tool made of copper, brass or carbon materials.

Electric spark machine:

Electrospark cutting of gears with internal meshing:

Electrospark cutting of gears with internal meshing:

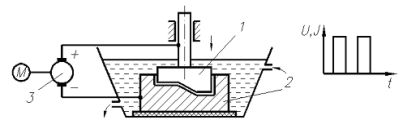

Modes of electric pulses characterized by the use of pulses of long duration (0.5 ... 10 s), corresponding to an arc discharge between the electrodes and more intense destruction of the cathode. In this regard, in electric pulse modes, the cathode is connected to the workpiece, which provides higher erosion performance (8-10 times) and less tool wear than in electric spark modes.

Modes of electric pulses characterized by the use of pulses of long duration (0.5 ... 10 s), corresponding to an arc discharge between the electrodes and more intense destruction of the cathode. In this regard, in electric pulse modes, the cathode is connected to the workpiece, which provides higher erosion performance (8-10 times) and less tool wear than in electric spark modes.

The most expedient field of application of electric pulse modes is the preliminary processing of workpieces of complex shaped parts (matrices, turbines, blades, etc.) made of hard-to-treat alloys and steels.

Electric pulse modes are implemented by installations (see fig.), in which unipolar pulses from an electric machine 3 or electronic generator… The emergence of E.D.S.induction in a magnetized body moving at a certain angle to the direction of the axis of magnetization makes it possible to obtain a current of greater magnitude.

Radiation treatment of metals

The types of radiation machining in mechanical engineering are electron beam or light beam machining.

The types of radiation machining in mechanical engineering are electron beam or light beam machining.

Electron beam processing of metals is based on the thermal effect of a stream of moving electrons on the processed material, which melts and evaporates at the processing site. Such intense heating is caused by the fact that the kinetic energy of the moving electrons, when they hit the surface of the workpiece, is almost completely transformed into thermal energy, which, concentrated on a small area (no more than 10 microns), causes it to heat up to 6000˚C.

During dimensional processing, as is known, there is a local effect on the processed material, which during electron beam processing is provided by a pulse mode of electron flow with a pulse duration of 10-4 ... 10-6 s and a frequency of f = 50 … 5000 Hz.

The high concentration of energy during electron beam machining in combination with pulse action provides machining conditions where the surface of the workpiece located at a distance of 1 micron from the edge of the electron beam is heated to 300˚C. This enables the use of electron beam machining to cut parts, fabricate mesh foils, cut grooves, and machine 1-10 micron diameter holes in parts made from difficult-to-machine materials.

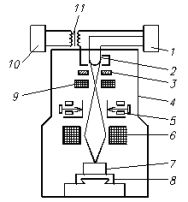

Special vacuum devices, so-called electron guns (see fig.), are used as equipment for electron beam processing.They generate, accelerate and focus an electron beam. The electron gun consists of a vacuum chamber 4 (with a vacuum of 133 × 10-4), in which a tungsten cathode 2 is installed, powered by a high-voltage source 1, which ensures the emission of free electrons that are accelerated by an electric field created between the cathode 2 and the anode membrane 3.

The electron beam then passes through a system of magnetic lenses 9, 6, an electrical alignment device 5 and is focused on the surface of the workpiece 7 mounted on the coordinate table 8. The pulse mode of operation of the electron gun is provided by a system consisting of a generator of pulses 10 and transformer 11.

A light beam processing method is based on the use of the thermal effects of the emitted light beam with high energy optical quantum generator (laser) on the surface of the workpiece.

Dimension processing with the help of lasers consists in the formation of holes with a diameter of 0.5 ... 10 microns in difficult-to-process materials, production of networks, cutting of sheets from complex profile parts, etc.