Automatic temperature control in electric ovens

In electric resistance furnaces, in the majority of cases, the simplest type of temperature control is used - two-position control, in which the executive element of the control system - the contactor has only two end positions: «on» and «off».

In electric resistance furnaces, in the majority of cases, the simplest type of temperature control is used - two-position control, in which the executive element of the control system - the contactor has only two end positions: «on» and «off».

In the on state, the temperature of the furnace rises, because its power is always selected with a margin, and the corresponding steady-state temperature significantly exceeds its operating temperature. When turned off, the temperature of the oven decreases exponentially.

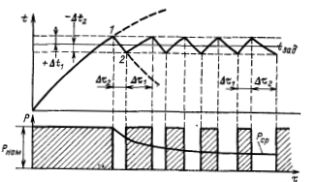

For the idealized case where there is no dynamic delay in the controller-furnace system, the operation of the on-off controller is shown in Fig. 1, in which the dependence of the furnace temperature on time is given in the upper part, and the corresponding change in its power in the lower part.

Rice. 1. Idealized scheme of operation of a two-position temperature regulator

When the furnace heats up, at the beginning its power will be constant and equal to the nominal one, so its temperature will rise to point 1 when it reaches the value Tbutt + ∆t1. At this point, the regulator will operate, the contactor will turn off the furnace and its power will drop to zero. As a result, the furnace temperature will begin to decrease along curve 1-2 until the lower limit of the dead zone is reached. At this point, the furnace will turn on again and its temperature will begin to rise again.

Thus, the process of regulating the temperature of the furnace according to the principle of two positions consists in its change along a saw curve around the set value in the intervals +∆t1, -∆t1 determined by the dead zone of the controller.

The average power of the furnace depends on the ratio of the time intervals of its on and off state. As the furnace heats up and charges, the furnace heating curve will become steeper and the furnace cooling curve will be flatter, so the cycle period ratio will decrease and therefore the average power Pav will also drop.

With two-position control, the average power of the oven is adjusted at all times to the power required to maintain a constant temperature. The dead zone of modern thermostats can be made very small and brought to 0.1-0.2 ° C. However, the actual fluctuations in the furnace temperature can be many times greater due to the dynamic delay in the controller-furnace system.

The main source of this delay is the inertia of the thermocouple sensor, especially if it is equipped with two protective shells, ceramic and metal.The greater this delay, the more the heater's temperature fluctuations exceed the controller's deadband. In addition, the amplitudes of these oscillations are highly dependent on the excess power of the furnace. The more the switching power of the furnace exceeds the average power, the greater these fluctuations are.

The sensitivity of modern automatic potentiometers is very high and can meet any requirement. On the contrary, the inertia of the sensor is large. Thus, a standard thermocouple in a porcelain tip with a protective cover has a delay of about 20-60 s. Therefore, in cases where temperature fluctuations are unacceptable, unprotected open-ended thermocouples are used as sensors. However, this is not always possible due to possible mechanical damage to the sensor, as well as leakage currents through the thermocouple in the devices, causing them to malfunction.

It is possible to achieve a reduction in the power reserve if the furnace is not turned on and off, but is switched from one power stage to another, and the higher stage should be only slightly more than the power consumed by the furnace, and the lower - not much less. In this case, the heating and cooling curves of the furnace will be very flat and the temperature will hardly exceed the dead zone of the device.

In order to make such a switch from one power stage to another, it is necessary to be able to adjust the furnace power smoothly or in steps. Such regulation can be carried out in the following ways:

1) switching furnace heaters, for example, from «triangle» to «star».Such a very rough regulation is associated with a violation of temperature uniformity and is used only in household electric heating appliances,

2) series connection with the furnace with adjustable active or reactive resistance. This method is associated with very large energy losses or a reduction in the power factor of the installation,

3) powering the furnace through a regulating transformer or an autotransformer with furnace switching at different voltage levels. Here, the regulation is also stepwise and relatively coarse, since the supply voltage is regulated, and the furnace power is proportional to the square of this voltage. In addition, there are additional losses (in the transformer) and reduction in power factor,

4) phase control with semiconductor devices. In this case, the furnace is powered by thyristors, the switching angle of which is changed by the control system. In this way, it is possible to obtain a smooth control of the furnace power over a wide range, almost without additional losses, using continuous control methods - proportional, integral, proportional-integral. In accordance with these methods, for each instant of time, the correspondence between the power absorbed by the furnace and the power released in the furnace must be fulfilled.

The most effective of all methods of temperature control in electric ovens is pulse regulation with thyristor regulators.

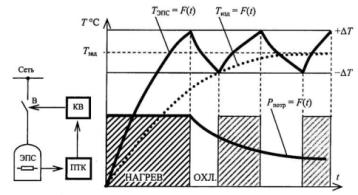

The pulse control process of the furnace power is shown in Fig. 2. The operating frequency of the thyristors is selected depending on the thermal inertia of the electric resistance furnace.

Rice. 2.Thyristor pulse temperature controller electric resistance furnace

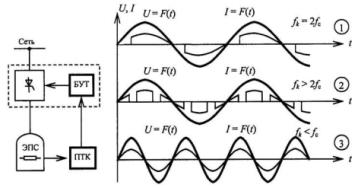

There are three main methods of heart rate regulation:

— pulse control at switching frequency — ek = 2ev (where ek is the frequency of the supply network current) with a change in the moment of ignition of the thyristor is called a phase pulse or phase (curves 1),

— pulse regulation with increased switching frequency is possible

— pulse regulation with reduced switching frequency (curves 3).

Through pulse control, it is possible to achieve a smooth power control over a wide range without additional losses, ensuring compliance with the consumed furnace and the power supply from the network.

Rice. 3. Connection diagram of the continuous temperature regulator

The main elements of the circuit: BT — thyristor block consisting of 6 thyristors, connected two in parallel in each phase of the furnace, BUT — thyristor control block, generates a signal to the thyristor control electrodes, PTC — heat control device, receives a signal from temperature sensor, processes and outputs a discrepancy in NO, PE — potentiometer element, has a slider moved by ED with a mechanical transmission, depending on the DT signal, DT — temperature sensor (thermocouple), ISN — stabilized DC voltage source, KL — linear contactor, VA1, VA2 — automatic switches to protect circuits from short circuits.