Application of magnetic fields for technological purposes

For technological purposes, magnetic fields are mainly used for:

For technological purposes, magnetic fields are mainly used for:

- impact on metal and charged particles,

- magnetization of water and aqueous solutions,

- impact on biological objects.

In the first case magnetic field it is used in separators for the purification of various food media from metal ferromagnetic impurities and in devices for the separation of charged particles.

In the second, with the aim of changing the physico-chemical properties of water.

In the third — to control the processes of a biological nature.

In magnetic separators using magnetic systems, ferromagnetic impurities (steel, cast iron, etc.) are separated from the bulk mass. There are separators with permanent magnets and electromagnets. To calculate the lifting force of magnets, an approximate formula known from the general course of electrical engineering is used.

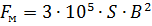

where Fm is the lifting force, N, S is the cross-section of a permanent magnet or magnetic circuit of an electromagnet, m2, V is the magnetic induction, T.

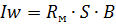

According to the required value of the lifting force, the required value of the magnetic induction is determined when an electromagnet is used, the magnetizing force (Iw):

where I is the current of the electromagnet, A, w is the number of turns of the coil of the electromagnet, Rm is the magnetic resistance equal to

here lk is the length of individual sections of the magnetic circuit with a constant cross section and material, m, μk is the magnetic permeability of the corresponding sections, H / m, Sk is the cross section of the corresponding sections, m2, S is the cross section of the magnetic circuit, m2, B is the induction, T.

Magnetic resistance is constant only for non-magnetic sections of the circuit. For magnetic sections, the value of RM is found using the magnetization curves, since here μ is a variable quantity.

Permanent magnetic field separators

The simplest and most economical separators are with permanent magnets, since they do not require additional energy to power the coils. They are used, for example, in bakeries to clean flour from ferrous impurities. The total lifting force of the tape recorders in these separators, as a rule, should be at least 120 N. In a magnetic field, the flour should move in a thin layer, about 6-8 mm thick, with a speed of no more than 0.5 m / s.

Permanent magnet separators also have significant disadvantages: their lifting force is small and weakens over time due to the aging of the magnets. Separators with electromagnets do not have these disadvantages, since the electromagnets installed in them are powered by direct current. Their lifting force is much higher and can be adjusted by the coil current.

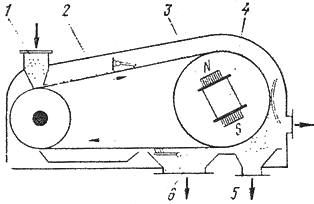

In fig. 1 shows a diagram of an electromagnetic separator for bulk impurities.The separation material is fed into the receiving hopper 1 and moves along the conveyor 2 to the drive drum 3 made of non-magnetic material (brass, etc.). Drum 3 rotates around a stationary electromagnet DC 4.

Centrifugal force throws the material into the unloading hole 5, and the ferro-impurities under the action of the magnetic field of the electromagnet 4 "stick" to the conveyor belt and are detached from it only after they leave the field of action of the magnets falling into the unloading hole for ferro- impurities 6. The thinner the product layer on the conveyor belt, the better the separation.

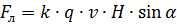

Magnetic fields can be used to separate charged particles in dispersed systems. This separation is based on Lorentz forces.

where Fl is the force acting on a charged particle, N, k is the proportionality factor, q is the particle charge, C, v is the particle velocity, m / s, N is magnetic field strength, A / m, a is the angle between the field and velocity vectors.

Positively and negatively charged particles, ions are deflected in opposite directions under the action of Lorentz forces, in addition, particles with different velocities are also sorted in a magnetic field in accordance with the magnitudes of their velocities.

Rice. 1. Diagram of an electromagnetic separator for bulk impurities

Devices for magnetizing water

Numerous studies conducted in recent years have shown the possibility of effective application of magnetic treatment of water systems — technical and natural waters, solutions and suspensions.

During the magnetic treatment of water systems, the following occurs:

- acceleration of coagulation — adhesion of solid particles suspended in water,

- formation and improvement of adsorption,

- the formation of salt crystals during evaporation not on the walls of the vessel, but in the volume,

- accelerating the dissolution of solids,

- change in the wettability of solid surfaces,

- change in concentration of dissolved gases.

Since water is an active participant in all biological and most technological processes, changes in its properties under the influence of a magnetic field are successfully used in food technology, medicine, chemistry, biochemistry, and also in agriculture.

With the help of local concentration of substances in a liquid, it is possible to achieve:

- desalination and improvement of the quality of natural and technological waters,

- cleaning liquids from suspended impurities,

- control the activity of food physiological and pharmacological solutions,

- control of the processes of selective growth of microorganisms (acceleration or inhibition of the rate of growth and division of bacteria, yeast),

- control of the processes of bacterial leaching of wastewater,

- magnetic anesthesiology.

Controlling the properties of colloidal systems, dissolution and crystallization processes is used to:

- increasing the efficiency of the thickening and filtration processes,

- reduction of deposits of salts, scale and other accumulations,

- improving plant growth, increasing their yield, germination.

Let's note the features of magnetic water treatment. 1. Magnetic treatment requires the mandatory flow of water at a certain speed through one or more magnetic fields.

2.The effect of magnetization does not last forever, but disappears some time after the end of the magnetic field, measured in hours or days.

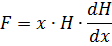

3. The effect of the treatment depends on the induction of the magnetic field and its gradient, the flow rate, the composition of the water system and the time it is in the field. It is noted that there is no direct proportionality between the treatment effect and the magnitude of the magnetic field strength. The tilt of the magnetic field plays an important role. This is understandable if we consider that the force F acting on a substance from the side of a non-uniform magnetic field is determined by the expression

where x is the magnetic susceptibility per unit volume of the substance, H is the magnetic field strength, A / m, dH / dx is the intensity gradient

As a rule, the magnetic field induction values are in the range 0.2-1.0 T, and the gradient is 50.00-200.00 T / m.

The best results of the magnetic treatment are achieved at a flow rate of water in the field equal to 1–3 m/s.

Little is known about the influence of the nature and concentration of substances dissolved in water. It was found that the magnetization effect depends on the type and amount of salt impurities in the water.

Here are some projects of installations for magnetic treatment of water systems with permanent magnets and electromagnets powered by currents of different frequencies.

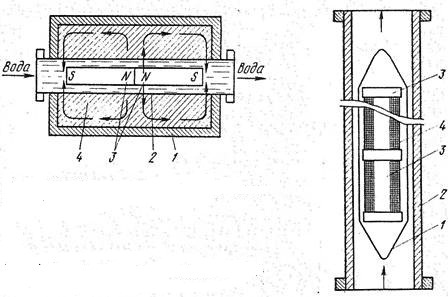

In fig. 2.shows a diagram of a device for magnetizing water with two cylindrical permanent magnets 3, Water flows in the gap 2 of the magnetic circuit formed by a hollow ferromagnetic core 4 placed in a case L The induction of the magnetic field is 0.5 T, the gradient is 100.00 T / m The width of the gap 2 mm.

Rice. 2. Scheme of a device for magnetizing water

Rice. 3.Device for magnetic treatment of water systems

Appliances equipped with electromagnets are widely used. A device of this type is shown in fig. 3. It consists of several electromagnets 3 with coils 4 placed in a diamagnetic coating 1. All this is located in an iron pipe 2. Water flows into the gap between the pipe and the body, protected by a diamagnetic cover. The strength of the magnetic field in this gap is 45,000-160,000 A / m. In other versions of this type of apparatus, the electromagnets are placed on the tube from the outside.

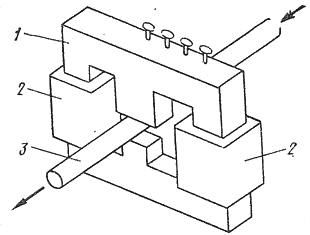

In all considered devices, water passes through relatively narrow gaps, therefore it is pre-cleaned from solid suspensions. In fig. 4 shows a diagram of a transformer type apparatus. It consists of a yoke 1 with electromagnetic coils 2, between the poles of which a tube 3 of diamagnetic material is laid. The device is used to treat water or cellulose with alternating or pulsating currents of different frequencies.

Only the most typical device designs that are successfully used in various areas of production are described here.

Magnetic fields also affect the development of the vital activity of microorganisms. Magnetobiology is a developing scientific field that is increasingly finding practical applications, including in the biotechnological processes of food production. The influence of constant, variable and pulsating magnetic fields on the reproduction, morphological and cultural properties, metabolism, enzyme activity and other aspects of the life activity of microorganisms is revealed.

The effect of magnetic fields on microorganisms, regardless of their physical parameters, leads to phenotypic variability of morphological, cultural and biochemical properties. In some species, as a result of treatment, the chemical composition, antigenic structure, virulence, resistance to antibiotics, phages and UV radiation can change. Sometimes magnetic fields cause direct mutations, but more often they affect extrachromosomal genetic structures.

There is no generally accepted theory explaining the mechanism of the magnetic field on the cell. Probably, the biological effect of magnetic fields on microorganisms is based on the general mechanism of indirect influence through the environmental factor.