Non-impregnated fibrous electrical insulating materials

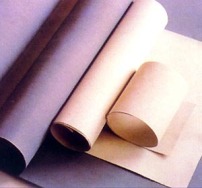

Non-impregnated fibrous electrical insulating materials include wood, as well as sheet and roll materials consisting of fibers of organic and inorganic origin. Fibrous materials of organic origin (paper, cardboard, fibers and fabrics) are obtained from plant fibers of wood, cotton and natural silk.

Non-impregnated fibrous electrical insulating materials include wood, as well as sheet and roll materials consisting of fibers of organic and inorganic origin. Fibrous materials of organic origin (paper, cardboard, fibers and fabrics) are obtained from plant fibers of wood, cotton and natural silk.

The normal moisture content of insulation board, paper and fiber ranges from 6 to 10%. Fibrous organic materials based on synthetic fibers (nylon) have a moisture content of 3 to 5%. The same moisture content is approximately the same for materials obtained on the basis of inorganic fibers (asbestos, fiberglass).

The characteristic features of inorganic fiber materials are their non-flammability and high heat resistance (up togirl C). In most cases, these valuable properties are reduced when these materials are impregnated. electrical insulating varnishes.

Electrically insulating papers obtained mainly from wood pulp. The mica paper used in the production of mica strips has the highest porosity.

Electrically insulating papers obtained mainly from wood pulp. The mica paper used in the production of mica strips has the highest porosity.

Electrical cardboard made from a mixture of cotton fibers and wood (sulfate) cellulose fibers taken in different ratios. Increasing the cotton fiber content reduces the absorption and shrinkage of the board. Some types of electrical boxes are made entirely of wood pulp (EMC brand) or cotton fiber (EMT brand).

Electric boards designed for use in air have a denser structure than boards designed for use in oil.

Fiber is a monolithic material obtained by pressing sheets of paper, pre-treated with a heated solution of zinc chloride and washed in water. The natural color of the fiber is gray. Fibers of other colors (red, black) are obtained by introducing suitable dyes into the material. The fibers lend themselves to all types of mechanical processing (turning, milling, drilling, threading; stamped up to 6 mm thick). Fiber sheets can be formed after soaking their blanks in hot water.

Letheroid — thin (0.1-0.5 mm) sheet and roll fibers used for the production of various types of electrical insulating gaskets, washers and shaped products. In leaf fibers and in letheroids, the volume resistance is 108-1010 ohm-cm, and the moisture content is 8-10%. For fibers, the ultimate strength in static bending is on average 100 kg / cm2.

Letheroid — thin (0.1-0.5 mm) sheet and roll fibers used for the production of various types of electrical insulating gaskets, washers and shaped products. In leaf fibers and in letheroids, the volume resistance is 108-1010 ohm-cm, and the moisture content is 8-10%. For fibers, the ultimate strength in static bending is on average 100 kg / cm2.

Asbestos papers, cardboards and tapes are made of chrysotile asbestos fibers (3MgO • 2 SiO2 • 2H20), which have the greatest elasticity and ability to be wound into threads. Heat resistance of chrysotile asbestos fibers 550-600 ° C; the melting of asbestos fibers occurs at 1500 ° C.Asbestos fibers do not have internal capillaries, which is why their hygroscopicity is lower than that of plant fibers.

Due to the fact that asbestos contains about 3-4% of iron oxides FeO, Fe2O3, etc., as well as adsorption water (0.95%), the electrical characteristics of asbestos materials are relatively low (pv = 108-109 ohm-cm ).

I have iron asbestos containing up to 8% iron oxides, specific volume resistance pv = 105-106 ohm-cm

Semiconducting tapes are made from the filaments of ferroasbestos, which are used to equalize the electric field on the surface of the windings of high voltage electrical machines.

From chrysotile asbestos threads, take heat-resistant electrical insulation tapes. To ensure a high breaking strength of 140-145 kg / cm2, cotton fibers are introduced into the asbestos threads.

From chrysotile asbestos threads, take heat-resistant electrical insulation tapes. To ensure a high breaking strength of 140-145 kg / cm2, cotton fibers are introduced into the asbestos threads.

Chrysotile asbestos fibers are used to produce asbestos insulation paper with a thickness of 0.2 to 0.5 mm. To improve the mechanical characteristics, 15-25% cotton fibers (type A paper) are added to the asbestos fibers. In this case, the heat resistance of this material is somewhat reduced. Asbestos paper with increased heat resistance (type B) is made entirely of asbestos fibers.

Asbestos board is made from chrysotile asbestos fibers. In electrical insulation, this material is mainly used impregnated (with varnishes, resins).

All asbestos materials are resistant to bases, but are easily destroyed by acids.

Electrically insulating glass fabrics and tapes made from glass filaments obtained from alkaline (alkaline content not more than 2%) or low-alkaline (alkaline content not more than 6%) glasses.The diameter of the glass filaments (made of continuous or staple fibers) is in the range of 3-9 microns.

The advantage of glass fibers over vegetable and asbestos fibers is their smooth surface, which reduces the absorption of moisture from the air. The hygroscopicity of glass fabrics and tapes is in the range of 2-4%. The heat resistance of glass fabrics and tapes is higher than asbestos.