Asynchronous motors of the 4A series

Asynchronous motors of the basic version of the 4A series, along with general industrial ones, are designed to drive various equipment (metal cutting machines, mechanisms and machines). These motors are available in capacities from 0.06 to 400 kW with a rotation axis of 50 to 355 mm.

Asynchronous motors of the basic version of the 4A series, along with general industrial ones, are designed to drive various equipment (metal cutting machines, mechanisms and machines). These motors are available in capacities from 0.06 to 400 kW with a rotation axis of 50 to 355 mm.

By degree of protection engines can be in two versions: closed blown P44 and protected P23. The latter are produced only in the basic version. In industry, 4A motors are used in non-explosive environments. Motors with power from 0.06 to 0.37 kW are produced for voltages of 220 and 380 V, and from 0.55 to 11 kW - for voltages of 220, 380 and 660 V, when the stator windings are connected by a triangle or star with three the wire ends.

When connecting the stator windings Δ/Y, the rated voltage of motors of the 4A series with a power of 15 to 110 kW 220/380 and 380/660 V and from 132 to 400 kW — 380/660 V. These motors have six output ends and are designed to operate at mains voltage fluctuations of -5 to + 10% and current frequency ± 2.5% of the nominal value.

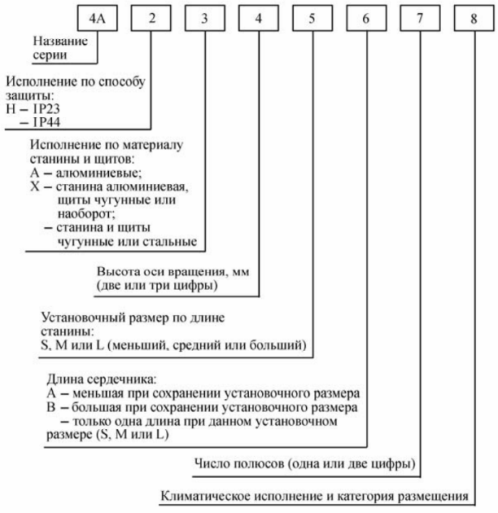

The first digit 4 of the reference designation indicates the serial number of the series, the letter A after the digit means motor type (asynchronous)… The letter A may be followed by the letter H, which means that the engine is protected, the absence of the letter H means that the engine is closed and blown. In addition, the designation indicates the design of the engine according to the material of the bed and shields: the letter A indicates that the bed and shields are aluminum, the letter X indicates that they are made of any combination of cast iron and aluminum, the absence of signs means that the bed and shields are made of steel or cast iron.

Two or three numbers in the designation indicate the height of the axis of rotation. The installation size along the length of the bed is characterized by the letters 5, M or L that appear after the numbers. When maintaining the mounting dimensions, the length of the stator core is indicated by the letters A or B. The absence of letters indicates the presence of only one length of the core. The last digits indicate the number of poles. The designations UZ, T2 or T1 indicate the climatic version and the placement category.

For example, 4AN280M6UZ means: the fourth single series 4A with a protected design with a rotation axis of 280 mm height and mounting size M, the motor has 6 poles, climate design and placement category UZ. Engines of the 4A series are produced with a shaft with cylindrical shaft ends: without a key with a diameter of 22, 32 and 40 mm, a length of 60, 160 and 200 mm at 3000 and 6000 min-1, with a key ( with a shaft length of 55, 100 and 130, the length of the key equal to 32, 80 and 120 mm, respectively). At a speed of 3000 min-1, as well as with a threaded part at a speed of 12000 and 18000 min-1, the motors are provided for the attachment of protective guards.

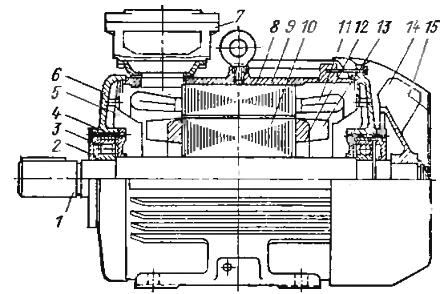

Asynchronous motor with a squirrel-cage rotor 4A: 1 — shaft, 2 — outer bearing cover, 3 — bearing, 4 — inner bearing cover, 5 — duct shield, 6 — bearing shield, 7 — input device, 8 — frame, 9 — stator core, 10 — rotor core, 11 — stator winding, 12 — rotor winding, 13 — rotor ventilation blades, 14 — fan, 15 — housing.

Along with the basic design, electrical modifications of the 4A series were developed, for example motors with increased starting torque, increased slip, multi-speed and built-in brake motors.

For drives of mechanisms with large static and inertial loads (compressors, conveyors, pumps, etc.), motors with increased starting torque at the time of starting are used. In these motors, the rotor is made with a double catenary cage cast from aluminum, which provides an increase of starting torque and reduction of inrush current.

Motors with increased slip are used to drive mechanisms operating in intermittent modes with frequent starts or pulsating load (piston compressors, sawmills, cranes, etc.). The rotor of these engines, unlike the basic version, has channels of reduced dimensions, in which a special alloy with increased resistance is poured. This allows for a soft mechanical response.

Two-, three- and four-speed motors are used from 500 to 3000 min-1 to drive mechanisms with stepped speed regulation (mechanisms for feeding woodworking machines, winches, etc.).

Unlike the basic version, when designating engines with increased starting torque, the letter P is added after the series, for example, 4AP160M4UZ.These motors are produced with a rotation axis from 160 to 250 mm high. When designating engines with increased slippage, the letter C is added after the series designation, for example, 4АС200М6УЗ. The height of the axis of rotation of these motors is 71-250 mm. In the designation of multi-speed motors, the number of poles is indicated additionally, for example, 4A10058 / 6 / 4UZ.

The 4A series motors are manufactured with low noise, built-in and built-in temperature protection. The low-noise ones are made with a rotation axis with a height of 56-160 mm. They operate in an environment with increased requirements for noise levels. In the designation of these engines, they write the letter H, for example, 4A160S6HV3. Motors built into mechanisms and metal cutting machines are made in the form of a wound stator core and rotor with and without a fan. In their designation, they write the letter B, for example, 4AV63A2UZ. These motors are available with IP44 protection.

Motors with built-in temperature protection are used to drive mechanisms operating with large overloads and frequent starts. In their designation, they write the letter B, for example, 4A132M4BUZ.

The following degrees of protection are provided for 4A series motors:

IP23 — protection against the possibility of contact of human fingers with live and / or moving parts in the machine, protected against solid foreign bodies with a diameter of at least 12.5 mm (number 2), protected against rain falling on the machine at an angle no more than 60° to the vertical (number 3), the alphabetic part of IP is the initial letters of the words International Protection.

IP44 - protection against the possibility of contact of a tool, wire or other similar objects, the thickness of which does not exceed 1 mm, with live or moving parts in the machine (first digit 4), protected against splashes of water from any direction falling on the casing (second digit).

IP54 — full protection of personnel from contact with rotating and live parts in the machine, as well as protection from harmful dust deposits inside the machine.

Cooling motors of grade AzP44 and 1P54 is done by a centrifugal fan located on the motor shaft on the side opposite to the working end. He blows air along the ribs of the bed. The engine with the degree of protection 1P23 has a cooling system in the form of bilateral symmetrical radial ventilation.