Maintenance of electric motors

Current repairs are carried out to ensure and restore the operation of the electric motor. It consists in replacing or restoring individual parts. It is carried out at the place of installation of the machine or in the workshop.

Current repairs are carried out to ensure and restore the operation of the electric motor. It consists in replacing or restoring individual parts. It is carried out at the place of installation of the machine or in the workshop.

The frequency of current repair of electric motors is determined by the PPR system. It depends on where the motor is installed, the type of machine or machine it is used in, and the length of time it is run per day. Electric motors are mainly repaired once every 24 months.

When carrying out current repairs, the following operations are carried out: cleaning, disassembly, disassembly and detection of defects of the electric motor, replacement of bearings, repair of terminals, terminal box, damaged sections of coil windings, assembly of the electric motor, painting, idling and under load. For machines with direct current and electric motors with a phase rotor, the brush collection mechanism is additionally repaired.

Table 1 Possible malfunctions of electric motors and their causes

Malfunction Causes The electric motor does not start Open circuit in the power network or in the stator windings The electric motor does not rotate during starting, hums, heats up There is no voltage in one of the phases, the phase is interrupted, the electric motor is overloaded, the rotor bars are cut Reduced speed and hum Bearing wear, misalignment of end shields, shaft bending Motor stalls when load increases Undervoltage in the network, incorrect connection of windings, breakage of one of the stator phases, interruption of reversal, overload of the motor, breakage of the rotor winding (for a wound rotor motor) The motor makes a lot of noise when starting The fan casing is bent or foreign objects have fallen in The electric motor overheats during operation, the connection of the windings is correct, the noise is uniform High or low mains voltage, the electric motor is overloaded, the ambient temperature is high, the fan is defective or clogged, the surface of the motor is clogged The running motor has stopped Power supply interruption, long-term undervoltage, blocking of the mechanism Reduced resistance of the stator (rotor) winding Dirty or wet winding Excessive heating of motor bearings Out of alignment, defective bearings Increased overheating of the stator winding Phase interruption, overvoltage or undervoltage of the supply voltage, machine overload, short circuit from turn to turn, short circuit between winding phases When the electrical motor is on,protection is triggered Improperly connected stator windings, windings shorted to housing or to each other

Current repairs are carried out in a certain technological sequence. Before starting the repair, it is necessary to review the documentation, determine the operating time of the electric motor bearings and determine the presence of outstanding defects. A craftsman is appointed to carry out the work, the necessary tools, materials, devices, especially lifting mechanisms, are prepared.

Before starting disassembly, the electric motor is disconnected from the network, measures are taken to prevent accidental voltage supply. The machine to be repaired is cleaned of dust and dirt with brushes, blowing compressed air from the compressor. Unscrew the screws securing the cover of the terminal box, remove the cover and disconnect the cables (cables) powering the motor. The cable is retracted, respecting the necessary bending radius, so as not to damage it. Bolts and other small parts fold into a box that is included in a set of tools and accessories.

When disassembling the electric motor, it is necessary to put marks on the core to fix the position of the coupling halves relative to each other, as well as to note which hole in the coupling the half of the pin fits into. The pads under the legs must be tied and marked so that after repair, each group of pads is installed in its place, this will facilitate the alignment of the electric machine. Covers, flanges and other parts must also be marked. Otherwise, re-disassembly may be required.

Remove the electric motor from the base or workplace using the bolts. Do not use a shaft or end shield for this purpose. Lifting devices are used for removal.

The dismantling of the motor is carried out in compliance with certain rules. It starts with removing the coupling half from the shaft. In this case, manual and hydraulic pulls are used. Then the fan housing and the fan itself are removed, the bolts for attaching the bearing shields develop, the rear end shield is removed with light bumps with a hammer on the extension of wood, copper, aluminum, the rotor is removed from the stator, the front shield is removed, the bearings are dismantled.

After disassembly, the parts are cleaned with compressed air using a hair brush for the windings and a metal housing brush, the end shields and the frame. The dried dirt is removed with a wooden spatula. Do not use a screwdriver, knife or other sharp objects. The detection of a malfunction of an electric motor ensures an assessment of its technical condition and the identification of defective nodes and parts.

When defecting the mechanical part, the following is checked: the condition of the fasteners, the lack of cracks in the housing and the covers, the wear of the seats of the bearings and the condition of the bearings themselves. For a DC machines, a serious component that must be considered is the whole brush collection mechanism.

There are damage to the brush holder, cracks and brushes on the brushes, wear of brushes, scratches and indentations on the surface of the collector, the protrusion of mycinte seals between the plates. Most of the malfunctions of the brush collection mechanism are eliminated during routine repairs.In case of serious damage to this mechanism, the machine is sent for overhaul.

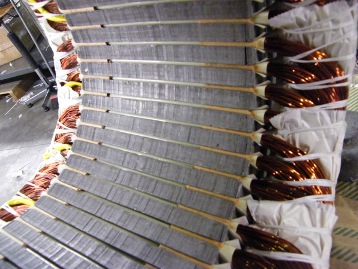

Malfunctions in the electrical part are hidden from the human eye, their detection is more difficult, special equipment is needed. In this case, the number of stator winding failures is limited by the following defects: open circuit, short circuit of individual circuits to each other or to the box, turn short circuit.

A break in the winding and its short circuit to the case can be detected using a megohmmeter. Rotation closure is determined using the EL-15 apparatus. A break in the squirrel cage rotor bars was found on a special installation. Eliminated malfunctions during routine repairs (damage to the front parts, breakage or burning of the output ends) can be established with a megohmmeter or visually, in some cases an EL-15 device is required. During fault detection, the insulation resistance is measured to determine the need for drying.

The repair of the DC motor is as follows. When the thread breaks, a new one is cut (for further use, a thread with no more than two cut threads is allowed), the bolts are replaced, the cover is welded. Damaged windings are covered with several layers of insulating tape or replaced if their insulation there are cracks, delamination or mechanical damage along the entire length.

If the faces of the stator winding are damaged, an air-dried varnish is applied to the defective area. Bearings are replaced with new ones if there are cracks, chips, dents, discoloration or other malfunctions.The landing of a bearing on a shaft is usually carried out by preheating to 80 ... 90 ° C in an oil bath.

The installation of bearings is carried out manually using special chucks and a hammer or mechanically using a pneumohydraulic press. It should be noted that due to the introduction of a single series of electric machines, the volume of repair of the mechanical part has sharply decreased, since the number of varieties of end shields and covers decreased, it became possible to replace them with new ones.

The procedure for assembling an electric motor depends on its size and design features. For electric motors of sizes 1 - 4, after pressing the bearing, the front end shield is installed, the rotor is inserted into the stator, the rear shield is placed, the fan and cover are put in and fixed, then the half-coupling is installed. In addition, depending on the scope of the current repair, idling, articulation with the working machine and load testing are carried out.

Checking the operation of the electric motor at idle speed or with an unloaded mechanism is carried out as follows. After checking the operation of the protection and the alarm, a trial run is carried out with listening for knocking, noise, vibration and subsequent shutdown. After that, the electric motor is started, the acceleration to the rated speed and the heating of the bearings are checked, the no-load current of all phases is measured.

The no-load current measured in individual phases should not differ from each other by more than ± 5%. A difference between them of more than 5% indicates a malfunction of the stator or rotor winding, a change in the air gap between the stator and the rotor, or a malfunction of the bearings.The duration of the inspection, as a rule, is at least 1 hour. The operation of the electric motor under load is carried out when the technological equipment is turned on.

Tests after repair of electric motors in accordance with current standards should include two checks - measurement of insulation resistance and protection effectiveness. For electric motors up to 3 kW, the insulation resistance of the stator winding is measured, and for motors over 3 kW additionally the absorption coefficient is measured… At the same time, for electric motors with a voltage of up to 660 V in the cold state, the insulation resistance must be at least 1 MΩ and at a temperature of 60 ° C — 0.5 MΩ. Measurements are made with a 1000 V megometer.

Testing the operation of the protection of machines up to 1000 V with a supply system with an earthed neutral is carried out by directly measuring the single-phase short-circuit current to the housing using special devices or by measuring the impedance of the "phase zero" circuit with subsequent determination of the single-phase short circuit current. The resulting current is compared with the rated current of the protective device, taking into account the PUE coefficients. It must be greater than the fuse current of the nearest fuse or circuit breaker.

In the process of carrying out current repairs, in order to improve the reliability of electric motors of old modifications, it is recommended to carry out modernization measures. The simplest of them is triple impregnation of the stator winding with varnish with the addition of an inhibitor.The inhibitor, dispersing into the varnish film and filling it, prevents the penetration of moisture. It is also possible to encapsulate the front ends with epoxy resins, but the engine may become irreparable.