How to ensure the safety of elevators

In this article, we will talk about elevator safety. We are so used to elevators that sometimes we don't even think about their condition, about our safety, about whether the elevators of our houses are serviced in a timely manner. Meanwhile, these questions are by no means empty. How do we and our loved ones not get into an accident in the elevator? How to prevent accidents, what should you pay attention to? What else do you need to know about elevators? We will answer these and other questions in this article.

With timely and proper maintenance, the elevator becomes one of the safest vehicles. Strict technical control and trouble-free operation of the elevator safety system completely exclude any possibility of accidents.

On the territory of the Russian Federation, the regulation of the Customs Union TR CU 011/2011 "Safety of elevators" is in force, which establishes the minimum requirements for ensuring this safety and based on which international standards are adopted, which are mandatory. From May 13, 2013The Federal Service for Environmental, Technological and Nuclear Supervision oversees the safety of elevators in the Russian Federation, and the Federal Agency for Technical Regulation and Metrology oversees the commissioning of elevators.

Catchers

To prevent accidents in elevators, they are first and foremost safety and speed limiters… Catchers are mounted on the car or on a counterweight, and in case of a dangerous situation they catch the drivers to stop the elevator car and hold it firmly at any height in the shaft.

As for speed limiters, these are devices that control the speed of the elevator car and the counterweight. The speed limiter is activated when the car's maximum descent speed exceeds the regulation for a certain type of elevator with the maximum permissible deviation and automatically activates the safety devices.

Arrestors are installed on all modern elevators, and if the elevator shaft is located above a room or passage where people can be, if the floors under the elevator shaft are not strong enough, the counterweights are also equipped with arresters. In this case, trouble-free operation is guaranteed by the reliable operation of the speed limiter, which must be regularly checked and, if necessary, adjusted.

Elevators whose speed is 1 m / s and more, as well as elevators of hospitals and institutions with a medical and preventive profile, are equipped with arresters for smooth stopping. The braking distance is regulated by the rules, and the corresponding setting of the safety devices is carried out according to the tables given in them.

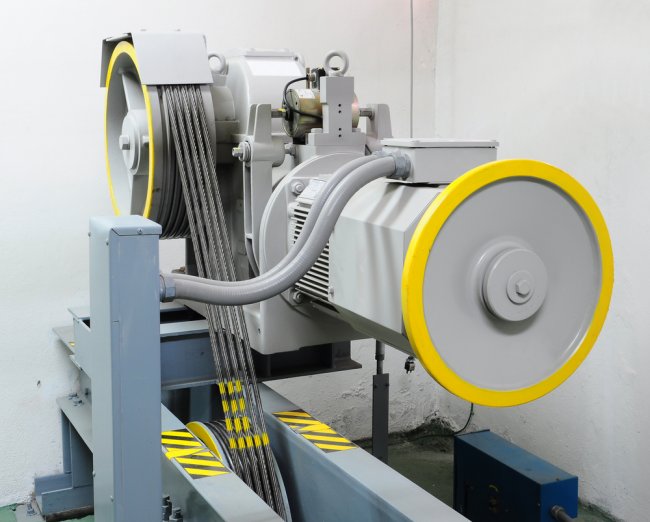

The speed limiter is a centrifugal regulator, the eccentric masses of which at a certain speed catch the shoe and stop. The mechanism is connected to a speed limiter rope and a tensioner located in the pit. When the speed exceeds the permissible value, the contact device turns off the winch and stops the elevator until the causes of the dangerous situation are determined.

The limiter is connected to a safety device that captures the rail and stops the moving parts of the elevator, keeping the car stationary and rigid. According to the nature of the increase in force in the elements of the safety devices during the stop of the car or the counterweight, the safety devices are distinguished with hard (instant) action and smooth stop.

Fire hazard

In the event of a fire, after receiving a "Fire" signal from the building's fire alarm system, the elevator automatically switches to the "Fire Danger" mode. In this mode, the elevator starts moving towards the floor of the entrance to the firemen's building.

In the "Fire Danger" mode, the elevator does not respond to calls and from any current position begins to move to the floor of the firemen's entrance to the building, automatically closing the doors. This is necessary in order to extinguish a fire in a timely manner.

When the car arrives at the floor of the entrance to the fire building, the elevator remains in the stop state with the doors open and is taken out of the "Fire Hazard" mode. The elevator can also be moved manually from the machine room from a fire hazard to normal operation.

To inform people that an elevator arriving at the landing floor cannot be used to transport passengers, the "No Entry" indicator should be placed on the landing floor. The indicator turns on when the elevator arrives at the landing floor.

Prevention and vigilance

Residents of houses equipped with elevators and other users of elevators should be vigilant and not lose sight of the signs of wear on the elevator chassis, which are as follows:

-

the cabin deviates from the vertical when moving;

-

the cabin moves with sudden movements;

-

there is a sound of metal elements rubbing;

-

the cabin vibrates when moving;

-

the stop does not occur precisely (more than 35 mm) in the landing hole.

It is best to press the «call» button and inform the dispatcher about the signs of undercarriage wear. Also, the "call" button must be pressed if the cabin is stuck and there is no need to try to get out of the cabin on your own, this is fraught with falling into the shaft.

In general, the life expectancy of the elevator from the moment of installation is 25 years, and after this period, the entire security system and the chassis of the elevator must be diagnosed by the technical control department, which will then establish the permissible period for the further operation of the elevator and his fate. Once every 12 months, a technical inspection of the elevator must be carried out, and once a month - an inspection.

One of the most important means of ensuring the safe operation of elevators is their dispatcher control and the dispatcher systems used for this.If the regularity of technical checks is violated and the operation of the worn chassis continues, the lives of passengers in the elevator will be at risk.